2

Contents

VEGABAR 86 • 4 … 20 mA/HART

46321-EN-220624

Contents

1 For your safety ......................................................................................................................... 3

1.1 Authorised personnel ....................................................................................................... 3

1.2 Appropriate use................................................................................................................ 3

1.3 Warning about incorrect use............................................................................................. 3

1.4 General safety instructions............................................................................................... 3

1.5 EU conformity................................................................................................................... 3

1.6 SILqualicationaccordingtoIEC61508.......................................................................... 4

2 Product description ................................................................................................................. 5

2.1 Conguration.................................................................................................................... 5

3 Mounting................................................................................................................................... 6

3.1 General instructions for use of the instrument .................................................................. 6

3.2 Ventilation and pressure compensation............................................................................ 6

4 Connecting to power supply................................................................................................... 8

4.1 Connecting....................................................................................................................... 8

4.2 Single chamber housing................................................................................................... 9

4.3 Double chamber housing ................................................................................................. 9

5 Set up with the display and adjustment module ................................................................ 10

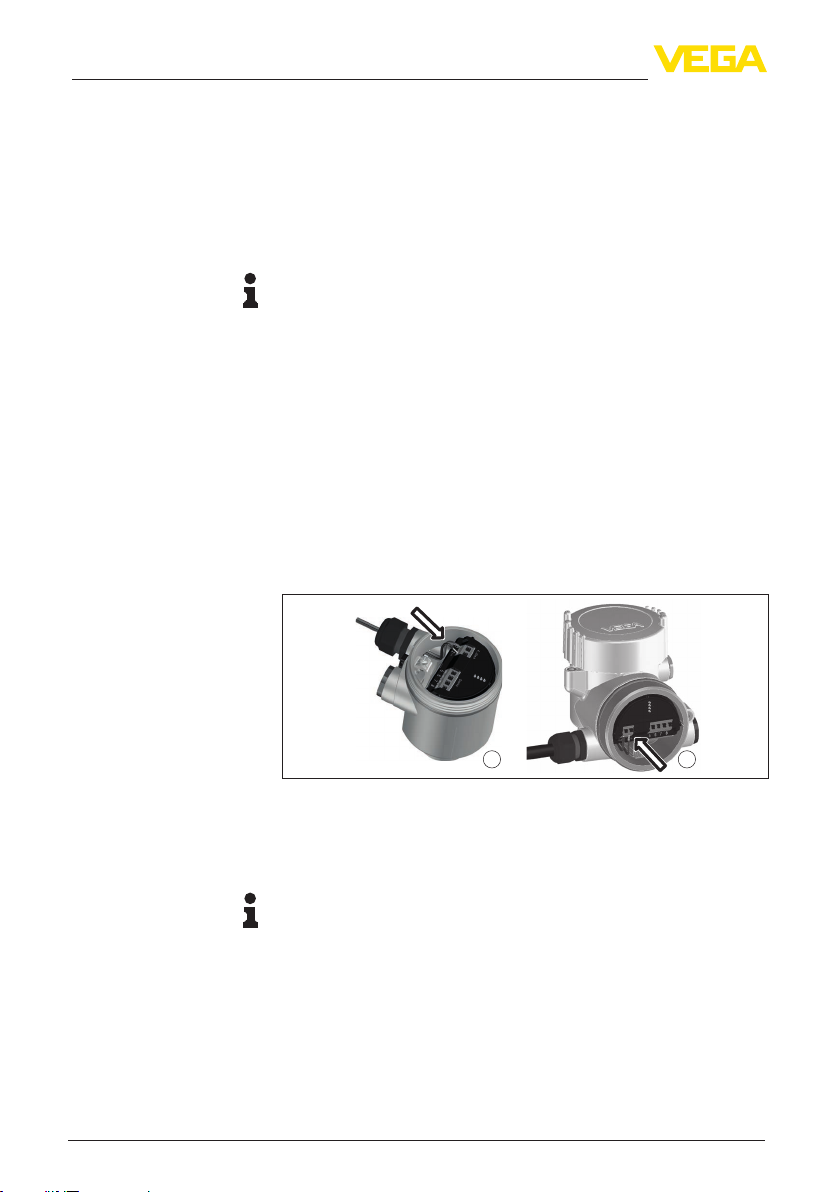

5.1 Insert display and adjustment module............................................................................ 10

5.2 Parameter adjustment .................................................................................................... 11

5.3 Menu overview ............................................................................................................... 14

6 Set up with smartphone/tablet, PC/notebook via Bluetooth ............................................. 16

6.1 Preparations................................................................................................................... 16

6.2 Connecting..................................................................................................................... 17

6.3 Sensor parameter adjustment........................................................................................ 17

7 Supplement ............................................................................................................................ 19

7.1 Technical data ................................................................................................................ 19

Information:

This quick setup guide enables quick setup and commissioning of

your instrument.

Youcanndsupplementaryinformationinthecorresponding,more

detailed Operating Instructions Manual as well as the Safety Manual

thatcomeswithinstrumentswithSILqualication.Thesemanualsare

available on our homepage.

Operating instructions VEGABAR 86 - 4 … 20 mA/HART:

Document-ID 45041

Safety Manual VEGABAR series 80 - Two-wire 4 … 20 mA/HART

with SIL qualication: Document-ID 48369

Editing status of the quick setup guide: 2022-04-20