Viega MegaPress 304 User manual

Other Viega Plumbing Product manuals

Viega

Viega 8330.2 User manual

Viega

Viega Prevista Dry 8522.33 User manual

Viega

Viega Prevista Dry Plus 8570.35 User manual

Viega

Viega Eco Plus User manual

Viega

Viega 8351.1 User manual

Viega

Viega Eco Plus User manual

Viega

Viega Eco Plus User manual

Viega

Viega Prevista 8524.19 User manual

Viega

Viega Multiplex 6171.10 User manual

Viega

Viega Eco Plus User manual

Viega

Viega 8139 User manual

Viega

Viega Prevista 8620.2 User manual

Viega

Viega Prevista Dry WC User manual

Viega

Viega 6168.5 User manual

Viega

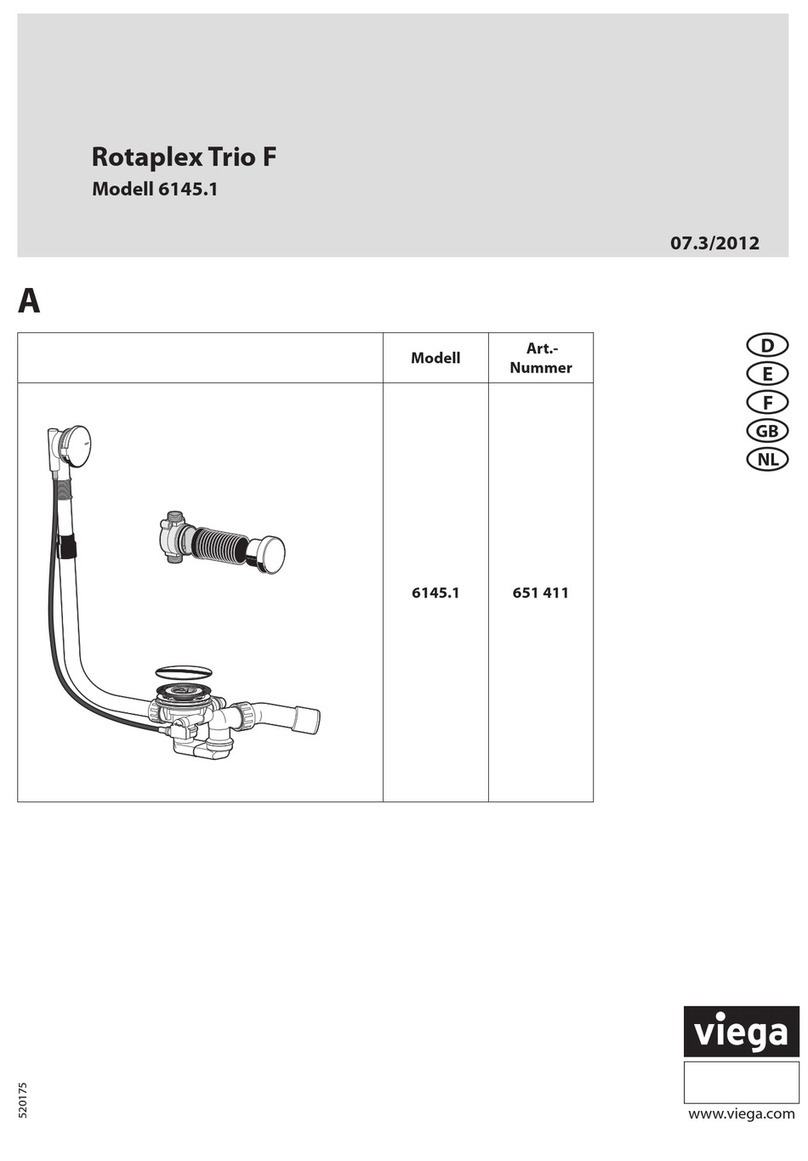

Viega Rotaplex Trio F User manual

Viega

Viega 8502 User manual

Viega

Viega 6161.86 User manual

Viega

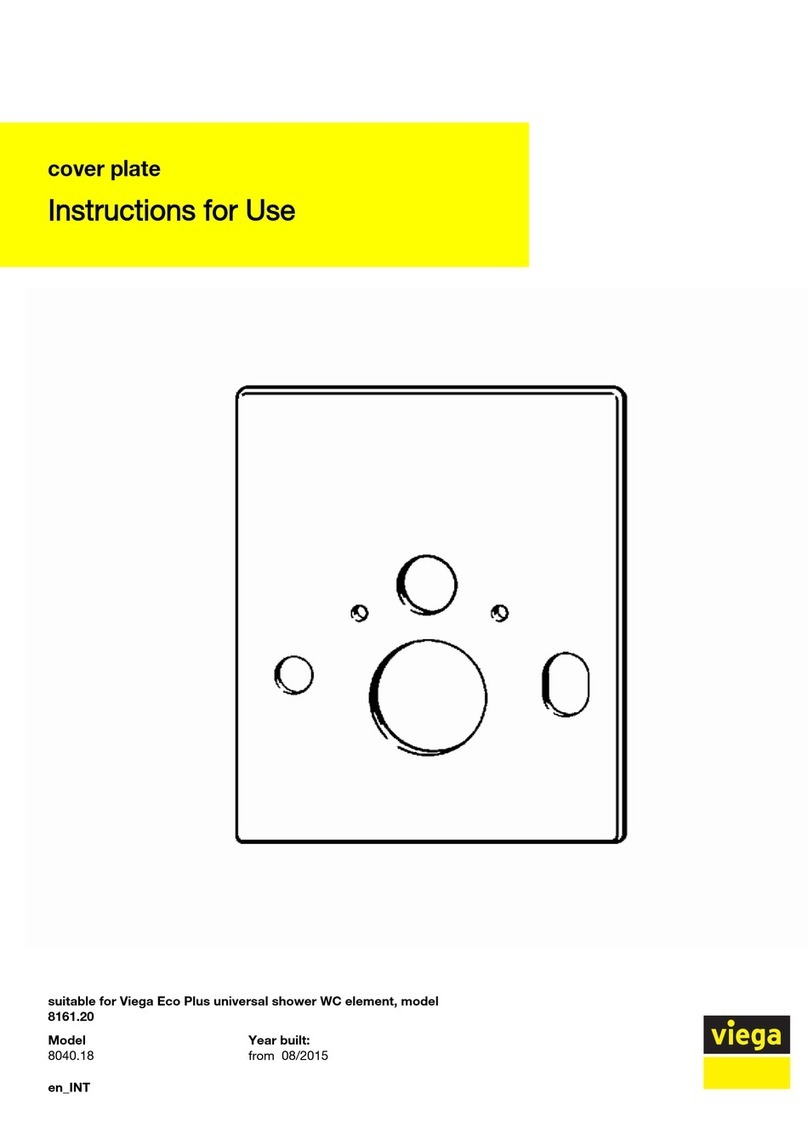

Viega 8040.18 User manual

Viega

Viega Prevista Dry 8573 User manual

Viega

Viega 6161.50 User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Kohler

Kohler K-12183 Homeowner's guide

Maxxus

Maxxus MX-M206-01 instruction manual

Kohler

Kohler Centerset K-15240 Homeowner's guide

Sanela

Sanela Lema SLP 59RB Instructions for use

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions