Group

21

Recondirioning

engine

Specificarions

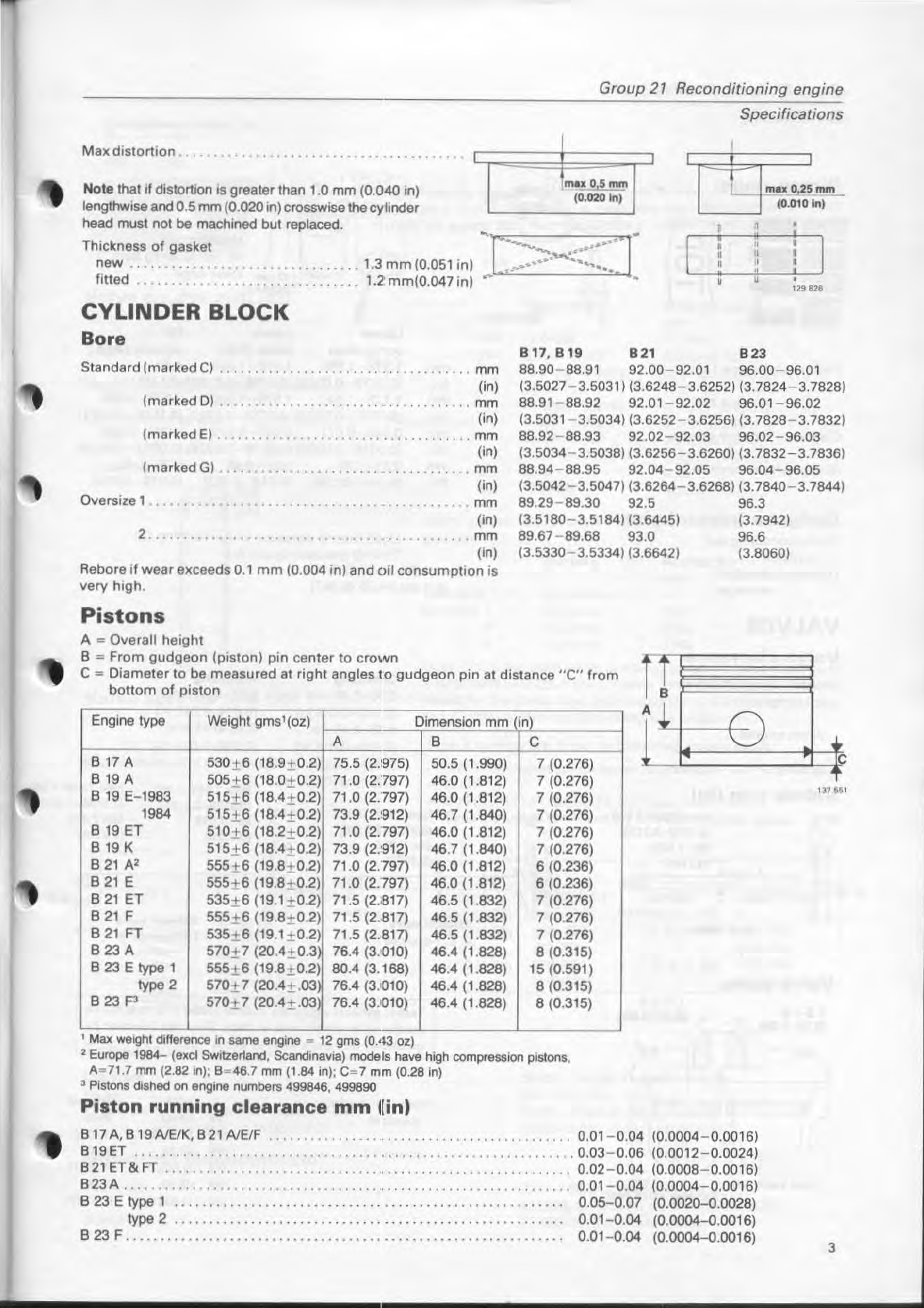

Max d

is

tortion

.....

I I

Na

te

thatll distortion is greater than 1.0 mm (0.040 in)

lengthwise and0.5 mm (0.020

in)

crosswisethecy1inder

head must not be machined but replaced.

mall 0

.5

mm

(0.

020

In) I

I

~

~'

-

10.010

ini

Th~~~~~~

~

.

f

.

~~~~~~

.............

.

..

1.3

mm

(0.051 in)

--

[>--~~::::~~T'

fitted 1.2

mm(0

.047 in)

~

~

CYLINDER

BLOCK

Bore

I • ,

i i

• ,

B17

,8

19

B21 8 23

.

i

,~~

Standard

(marked

el

..............................

mm 88.90-88.91 92.00-92.01 96.00-96.01

(i

n)

..

..........

mm

(in)

(3.5027-3.5031

~

(3.6248-3.6252~

(3.7824

-

3.7828~

(marked

D)

................

. 88.

91

-88.92 92.01- 92.02 96.

01

-96.02

(

3.5031

-3.5

034

~ (

3.6252

-

3.6256~

(3.7828-3.7832~

(marked

E)

...........

. . .

........

mm 88.92-88.93 92.02-92.03 96.02-96.03

(in)

.

mm

(in)

(

3.5034

-

3.5038~

(

3

.

6256

-

3

.

6260~

(3.7832-3.7836~

(marked

G)

. 88.94-88.95

92.04-92.05

96.04-96.05

(3.5

042

-

3

.S

047~

(3.6264-3.6268) (3.7840-3.7844)

Oversize 1

...

2.

..

.......

mm

(in)

.

..

mm

(in)

Rebore

ifwear

exceeds

0.1

mm

(0

.004 in)

and

oi!

c

onsumption

is

very high.

Pistons

A _ Overall height

B

'"

From

gudgeon

(

piston

) pin

center

to

crown

89

.29-

89.30 92.5 96.3

(3.5180- 3.S184) (3.6445) (3.7942)

89.67-89.68 93.0 96.6

(3.S33O- 3.5334) (3.6642)

(3

.8060)

e

'"

Diameter to

be

measured

at

right

angles

10

gudgeon

pin

at

dislan

ce "e" from

bottom

of

piston

Engine type Weight gms1(oz) Dimension mm

iN

A B C

817

A S30±6 (18.9±0.

2)

75.5 (2.975)

SO.5

(1.9901

7 (0.276)

819

A

5OS

±6 (18.0±0.2) 71

.0

(2.797) 46.0 (1.812) 7

(0

.276)

819

E- 1983 S15± 6 (18,4±0.2) 71.0 (2.797) 46.0 (1.812) 7 (0.276)

'984

S15t 6 (18,4±0.2) 73.9 (2.'91

2)

46.7 (1.640) 7 (0.276)

819

ET S10t 6 (18.2±0.2) 71.0 (2.797) 46.0 (1.812) 7 (0.276)

819

K S15±6 (18A±0.2) 73.9

(2.

'912)

46

.7 (1.840) 7 (0.276)

821

AZ

555±6 (19.8tO.2)

71

.0 (2.797) 46.0

(1

.812) 6 (0.236)

B

21

E 555±6 (l9.B ±0.2)

71

.0

(2

.797) 46.0 (1.812) 6 (0.236)

821

ET

535

±6 (19.1 t O.2) 71.5 (2.81

7)

46

.5 (1.832) 7 (0.276)

821

F

555

±6 (19.8tO.2) 71.5 (2.81

7)

46

.5 (1.832) 7 (0.276)

B

21

FT

535

±6 (19.1 t O.2) 71.5 (2.BI7)

46

.5 (1.832) 7 (0.276)

B23A

570

±7

(2O

.4±0.3 76.4 (3

.0

10)

46.4 (1.828) 8

(0

.315)

B23Elypel

555

±6 (19.8±0.2) 80.4

(3

.168) 46.4

(1

.828) 15

(0

.591)

typa 2

570

±7

(2O.4

±.

03 76.4

(3

.0

10)

46

.4 (1.828) 8 (0.315)

B23P

570

± 7 (20.4±.03 76.4 (3.010) 46,4

(1

.828) 8 (0.315)

I

Max

weight

ditlerence

'"

same

engine _

12

gms (OA3

Oz)

2Europe 1964-

(exel

Switzerland,

Scandinavl8)

medels have high compresslorl pistons,

A-

71.7

rTYTl

(2.82 in); 8_48

.7

mm

(1.84 in): C",7

mm

(0

.

28

in)

lplstons

dished

on

engine numbars 499846,

499890

Piston

running

clearance

mm

l[

in)

817A,B19A1E/K,B21A1E/F

............................

.

...............

0.01 -0.04

(0.0004-0.00

1

6)

819

ET

...................

0.03-0.06 (0.0012-0.0024)

821

ET&

FT

...........

..........

..

0.02-0.04 (0.0008-0.0016)

823A

..

................

.................

...

0.

01

- 0.04 (0.0004-0.001

6)

B 23 E type 1

......

. . . . . .

..

0.

OS

- 0.07 (0.0020-0.0028)

type 2

......

. . . . . . . . . . . . . . . . . . .

.. ..

0.Q1

-0.04 (0.0004-0.0016)

B 23 F

.........................................................

0.

01-0

.04 (0.0004-0.0016)

UJ

551

3