3

contents

HeavyCoat

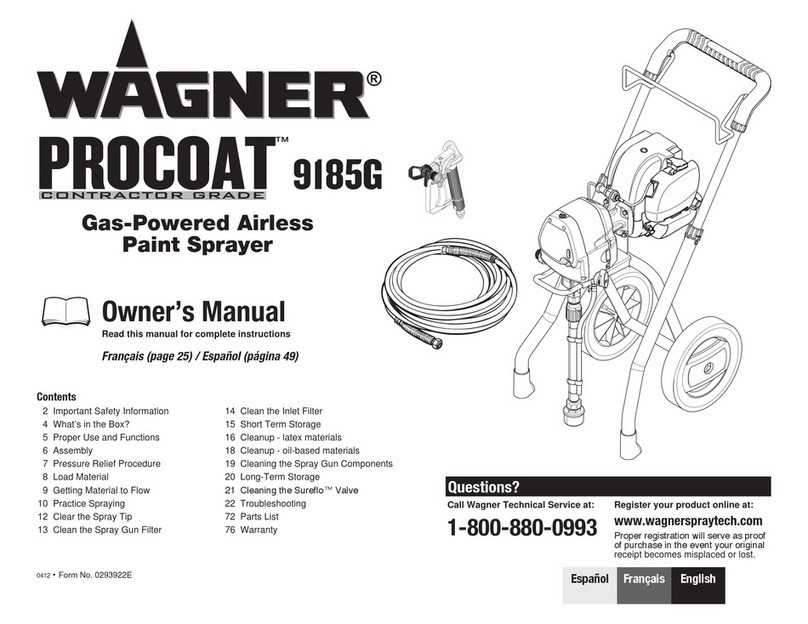

1 SAFETY REGULATIONS FOR AIRLESS

SPRAYING ______________________________ 4

1.1 Explanation of symbols used_____________________4

1.2 Safety hazards ________________________________4

1.3 Setup on an uneven surface _____________________6

1.4 Electrical safety _______________________________6

1.5 Gasoline engine safety__________________________6

1.6 Fueling (gas engine) ___________________________7

2 MAIN AREAS OF APPLICATION ____________ 8

2.1 Application___________________________________8

2.2 Coating materials______________________________8

3 DESCRIPTION OF UNIT ___________________ 9

3.1 Airless process ________________________________9

3.2 Functioning of the unit _________________________9

3.3 System diagram - gasoline HeavyCoat units _______10

3.4 System diagram - electric HeavyCoat units ________11

3.5 Technical data for HeavyCoat units ______________12

3.6 Transportation _______________________________13

3.7 Crane transport ______________________________13

4 OPERATION ____________________________ 13

4.1 Setup ______________________________________13

4.2 Starting the engine (gas models) ________________15

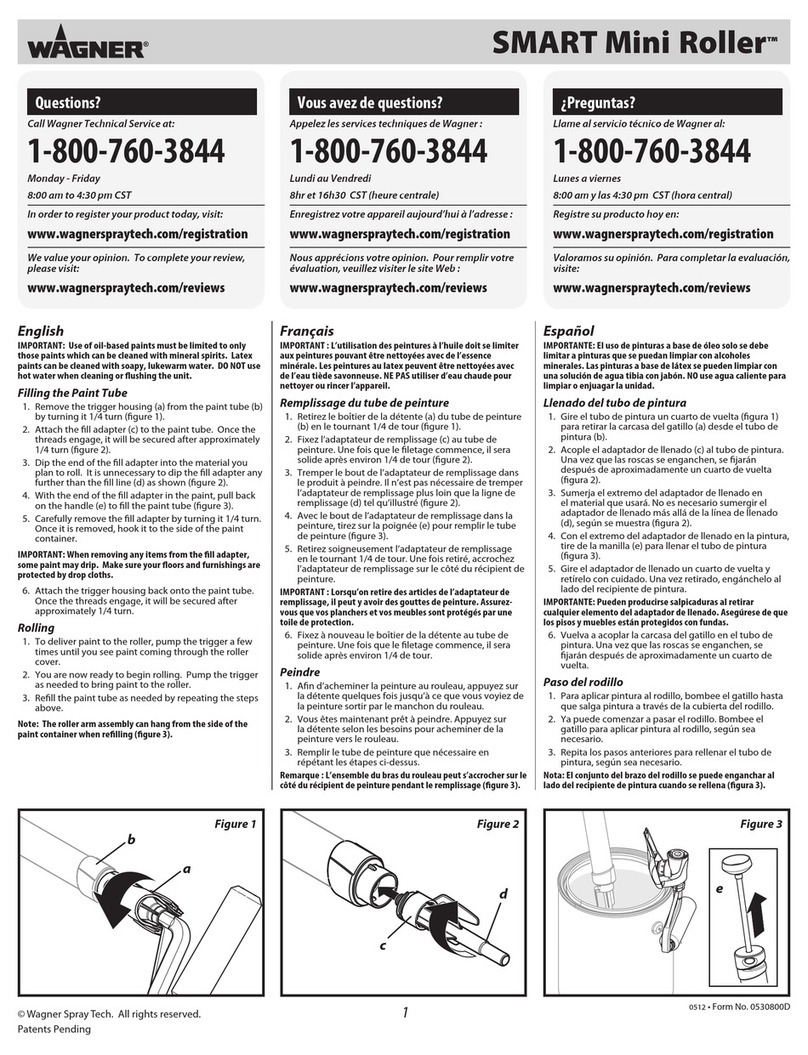

4.3 Preparing a new sprayer _______________________15

4.4 Preparing to paint ____________________________16

4.5 Painting ____________________________________17

4.6 Pressure relief procedure_______________________17

5 SPRAYING _____________________________ 18

5.1 Cleaning a clogged tip_________________________18

5.2 Interruption of work __________________________19

5.3 Handling the high pressure hose ________________19

6 CLEANUP ______________________________ 20

6.1 Special cleanup instructions for use with

ammable solvents ___________________________20

6.2 Cleaning the sprayer __________________________20

6.3 Cleaning the outside of the sprayer ______________20

6.4 Cleaning the lter screen_______________________21

6.5 Cleaning the airless spray gun __________________21

7 MAINTENANCE _________________________ 22

7.1 Daily maintenance____________________________22

7.2 Lubricating the upper packings _________________22

7.3 Maintaining the lter assembly__________________22

7.4 Maintaining the hydraulic system________________23

7.5 Maintaining the uid section ___________________24

7.6 High pressure hose ___________________________25

7.7 Basic engine maintenance______________________25

7.8 Servicing the hydraulic motor___________________26

7.9 Servicing the uid section ______________________28

7.10 Replacing the belt ____________________________30

8 TROUBLESHOOTING ____________________ 31

8.1 Airless gun __________________________________31

8.2 Fluid section_________________________________31

8.3 Hydraulic motors _____________________________32

8.4 Spray patterns _______________________________33

9 APPENDIX _____________________________ 34

9.1 Selection of tip _______________________________34

9.2 Servicing and cleaning of Airless hard-metal tips ___34

9.4 2Speed Tip table _____________________________35

9.5 Airless tip table____________________________ 36/37

ACCESSORIES AND SPARE PARTS ____________110

Spare parts list for the main assembly I____________ 110/111

Spare parts list for the main assembly II ___________ 112/113

Spare parts list for the cart assembly______________ 114/115

Spare parts list for the hydraulic system ___________ 116/117

Spare parts list for the uid section •

HeavyCoat 730 _______________________________ 118/119

Spare parts list for the uid section •

HeavyCoat 750 / 770 __________________________ 120/121

Spare parts list for the shovel valve HC 750 SSP ____ 122/123

Spare parts list for the hydraulic motor assembly ___ 124/125

Spare parts list for the high-pressure lter _________ 126/127

Spare parts list for bleed valve assembly __________ 128/129

Spare parts list for solenoid assembly_____________ 130/131

CONNECTION DIAGRAM 230V ______________132

CONNECTION DIAGRAM GAS ENGINE _______133

HYDRAULIC DIAGRAM ______________________134

ACCESSORIES FOR HC UNITS I _______________135

ACCESSORIES FOR HC UNITS II ___________136/137

IMPORTANT NOTES ON PRODUCT LIABILITY __138

3+2 YEARS GUARANTEE FOR PROFESSIONAL

FINISHING ________________________________138

SALES AND SERVICE COMPANIES ________147/148