2018553_b•en•2018-02-01 We reserve the right to make technical changes 1

Operating and installation instructions

MSE Compact 2/3/4/6 REG

Keep for future use!

Valid from 1 February 2018

General information

The MSE Compact 2/3/4/6 REG motor control unit is an

electronic control device for the non-floating control of

up to 6 sun shading drives. The MSE and drives have a

230VAC power supply.

Connected drives can be operated on-site with a suitable

operating element, and control through a sun shading con-

trol system is also possible. The required control voltage

of 24V DC is generated in the MSEs. Multiple MSEs can

be consolidated to a group and controlled together.

Intended use

The MSE Compact 2/3/4/6 REG motor control unit was

developed to control sun shading systems. The approval

of the manufacturer must be obtained for uses outside of

the purposes listed in these instructions.

Safety instructions

WARNING

The electrical installation must be per-

formed by a certified electrician in ac-

cordance with the electrical installation

regulations published by the Association

of German Electrical Engineers (VDE

0100) or the standards and regulations of

the country in which the device is being

installed. The electrician must observe the

installation instructions included with the

supplied electrical devices.

WARNING

If hazard-free operation cannot be assu-

med, the device may not be started or

must be deactivated. This assumption is

justified if:

the housing or the connecting lines show

signs of damage,

the device is no longer working.

WARNING

It is important to comply with the fol-

lowing points in the interest of personal

safety.

■Make sure that no persons or objects are located in the

path of any driven parts (blinds, roller shutters, etc.)!

■Disconnect the MSE from the operating voltage if

cleaning or other maintenance work must be performed!

Function

Tripping a switch on the subassembly can activate one of

the two integrated control programs for the run time for 2

motors each at the same time. The defined run time always

remains effective in pairs, regardless of any group that may

have been built.

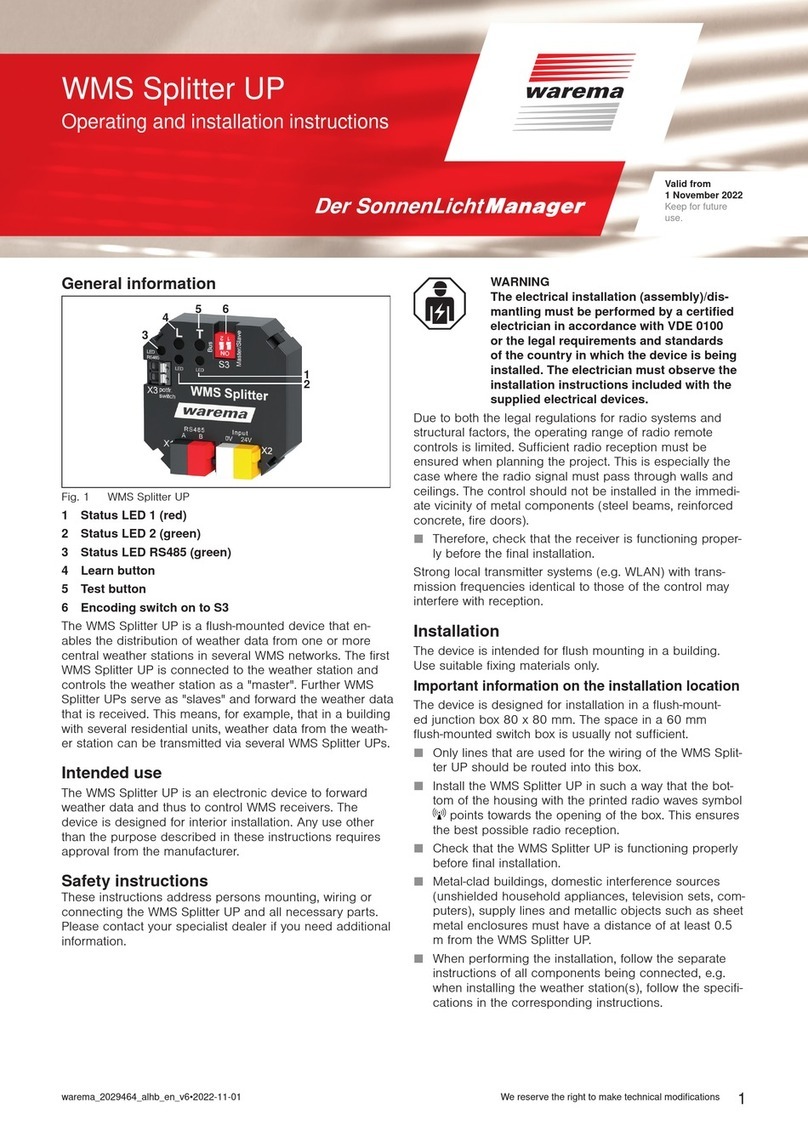

On the encoding switch you can perform the following set-

tings:

Motor Switch position Programme

1-2 S1 ON permanent mode

OFF* time mode

3-4 S2 ON permanent mode

OFF* time mode

5-6 S3 ON permanent mode

OFF* time mode

*= factory setting

ON

S1 S2 S3

Fig. 1 factory setting encoding switch

Program 1:

Local operation with time mode:

This control behaviour is especially useful for slat products,

such as external venetian blinds: The sun shading moves

into the corresponding direction after the button is pressed.

If the button is pressed for more than 2.5 seconds, the

control switches to lock mode. The button may then be

released. The sun shading system moves until the fixed run

time of 3 minutes has expired. To release lock mode and

stop the motor, the button opposite the move command

button must be pressed briefly. If you simply want to tilt the

slats, you can briefly touch one of the buttons.

Program 2:

Local operation in permanent mode:

This control behaviour is useful for roller shutters and fabric

products: the sun shading system moves after the local

button is pressed in the corresponding direction and im-

mediately goes into lock mode. The push button may then

be released and the sun shading system will move until

the fixed run time of 3 minutes has expired. To release lock

mode and stop the motor, the button opposite the move

command button must be pressed briefly.