1

warema_2029464_alhb_en_v6•2022-11-01 We reserve the right to make technical modifications

ARNINGW

The electrical installation (assembly)/dis-

mantling must be performed by a certified

electrician in accordance with VDE0100

or the legal requirements and standards

of the country in which the device is being

installed. The electrician must observe the

installation instructions included with the

supplied electrical devices.

Due to both the legal regulations for radio systems and

structural factors, the operating range of radio remote

controls is limited. Sufficient radio reception must be

ensured when planning the project. This is especially the

case where the radio signal must pass through walls and

ceilings. The control should not be installed in the immedi-

ate vicinity of metal components (steel beams, reinforced

concrete, fire doors).

Therefore, check that the receiver is functioning proper-

ly before the final installation.

Strong local transmitter systems (e.g. WLAN) with trans-

mission frequencies identical to those of the control may

interfere with reception.

Installation

The device is intended for flush mounting in a building.

Use suitable fixing materials only.

Important information on the installation location

The device is designed for installation in a flush-mount-

ed junction box 80 x 80 mm. The space in a 60 mm

flush-mounted switch box is usually not sufficient.

Only lines that are used for the wiring of the WMS Split-

ter UP should be routed into this box.

Install the WMS Splitter UP in such a way that the bot-

tom of the housing with the printed radio waves symbol

points towards the opening of the box. This ensures

the best possible radio reception.

Check that the WMS Splitter UP is functioning properly

before final installation.

Metal-clad buildings, domestic interference sources

(unshielded household appliances, television sets, com-

puters), supply lines and metallic objects such as sheet

metal enclosures must have a distance of at least 0.5

m from the WMS Splitter UP.

When performing the installation, follow the separate

instructions of all components being connected, e.g.

when installing the weather station(s), follow the specifi-

cations in the corresponding instructions.

General information

45

1

2

3

6

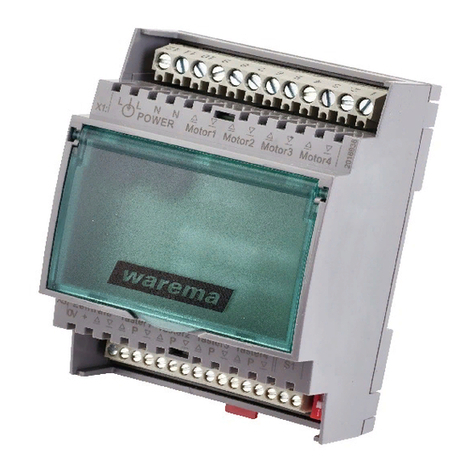

Fig. 1 WMS Splitter UP

1 Status LED 1 (red)

2 Status LED 2 (green)

3 Status LED RS485 (green)

4 Learn button

5 Test button

6 Encoding switch on to S3

The WMS Splitter UP is a flush-mounted device that en-

ables the distribution of weather data from one or more

central weather stations in several WMS networks. The first

WMS Splitter UP is connected to the weather station and

controls the weather station as a "master". Further WMS

Splitter UPs serve as "slaves" and forward the weather data

that is received. This means, for example, that in a building

with several residential units, weather data from the weath-

er station can be transmitted via several WMS Splitter UPs.

Intended use

The WMS Splitter UP is an electronic device to forward

weather data and thus to control WMS receivers. The

device is designed for interior installation. Any use other

than the purpose described in these instructions requires

approval from the manufacturer.

Safety instructions

These instructions address persons mounting, wiring or

connecting the WMS Splitter UP and all necessary parts.

Please contact your specialist dealer if you need additional

information.

Valid from

1 November 2022

Keep for future

use.

Operating and installation instructions

WMSSplitter UP