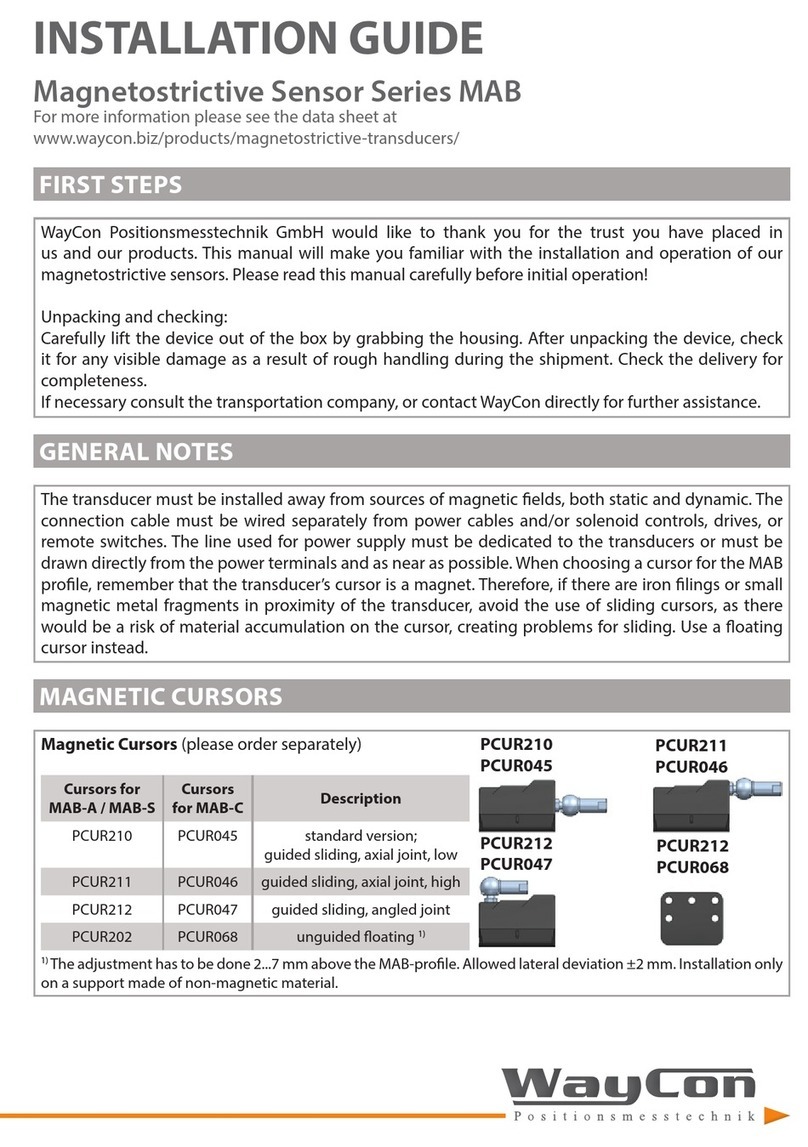

ACCESSORY CABLE

LAS-T5:

Cable with mating connector M12, female, 5 pins

K5PXM-S-M12 X m, straight connector, shielded

K5PXM-SW-M12 X m, angular connector, shielded

21

43

5

Pin Cable colour

1 BN

2 WH

3 BU

4 BK

5 GY

LAS-T, LAS-TL:

Cable with mating connector M12, female, 8 pins

K8PXM-S-M12 X m, straight connector, shielded

K8PXM-SW-M12 X m, angular connector, shielded 21

7

6

5

4

3

8

Pin Cable colour

1 WH

2 BN

3 GN

4YE

5 GY

6 PK

7 BU

8 RD

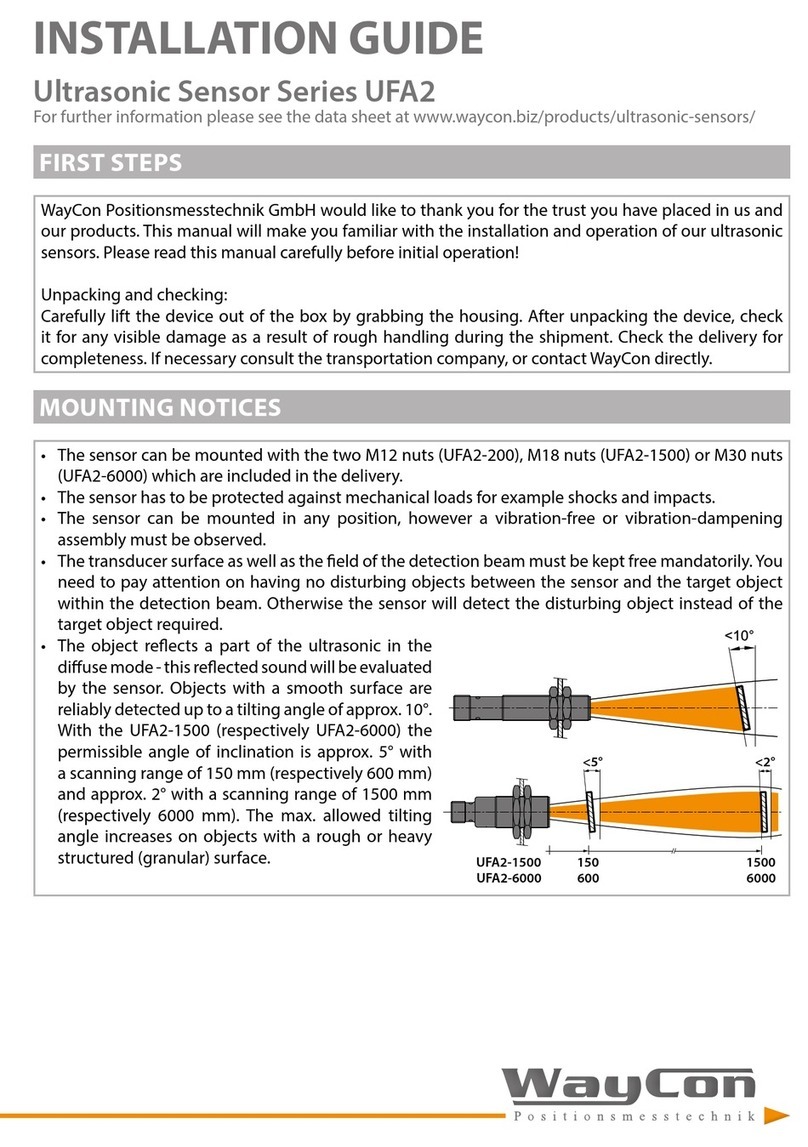

TROUBLESHOOTING

Error Possible cause Correction

The sensor does not

measure

The sync. input or the teach-in wire is

connected to + V.

Connect the sync. Input or the teach-in

wire to 0 V.

The receiving beam is covered by an

object / edge / step.

Make sure that no object blocks the laser

beam. Is the laser sot visible for the sensor?

No receiving signal (transparent or

highly reective object).

See gure 4 (above). If possible, use a

diuse reecting surface (e. g. white paint).

The sensor has incorrect

measuring values

Mutual optical interferences between

two or more sensors.

Switch o close sensors that might

inuence the receiving unit of the sensor.

Strong ambient light (e. g. direct sun

light).

Prevent ambient light with a shield.

Semi-transparent, transparent, or

highly reective objects.

Make sure that the laser spot falls on a

diuse reecting target.

The sensor does not reach

the specied accuracy

Rough surface A sensor with a laser line will work better.

Colour edges Mount the sensor the correct way.