7

Figure 1-3 PSR Rack Mount Unit for two Power Supplies

Arcus Installation Kit –A USB flash drive, with PDF documentation files,

and the Wheatstone application installer programs, ships with Arcus.

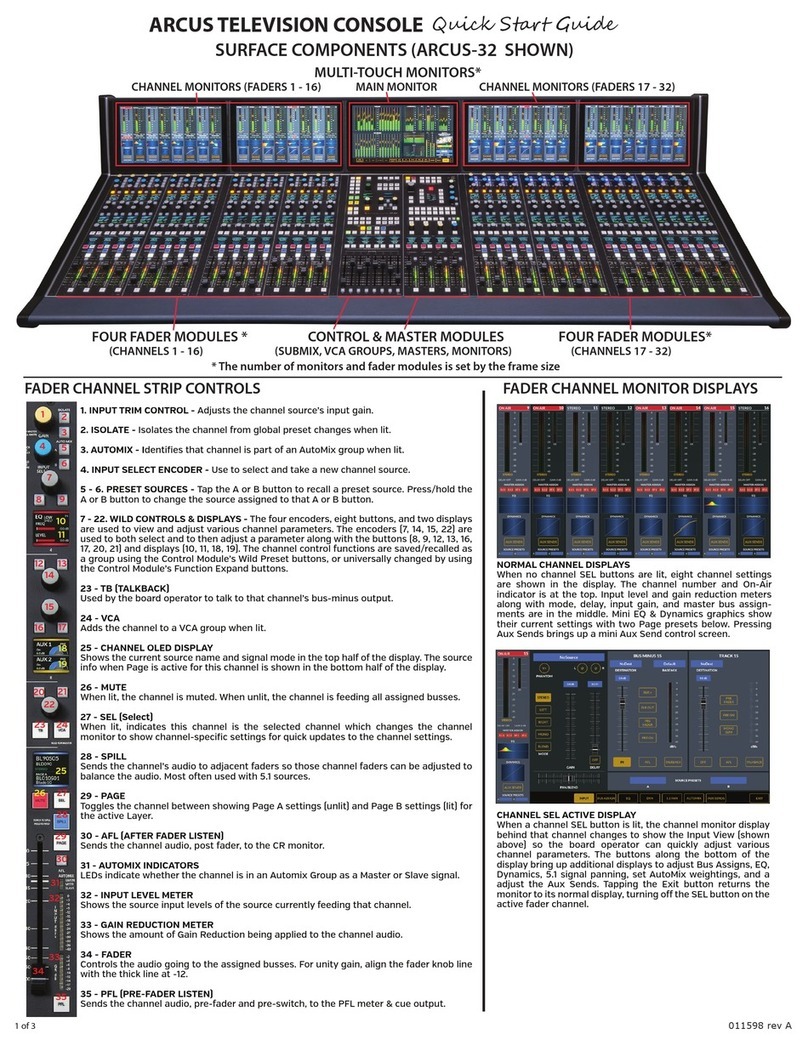

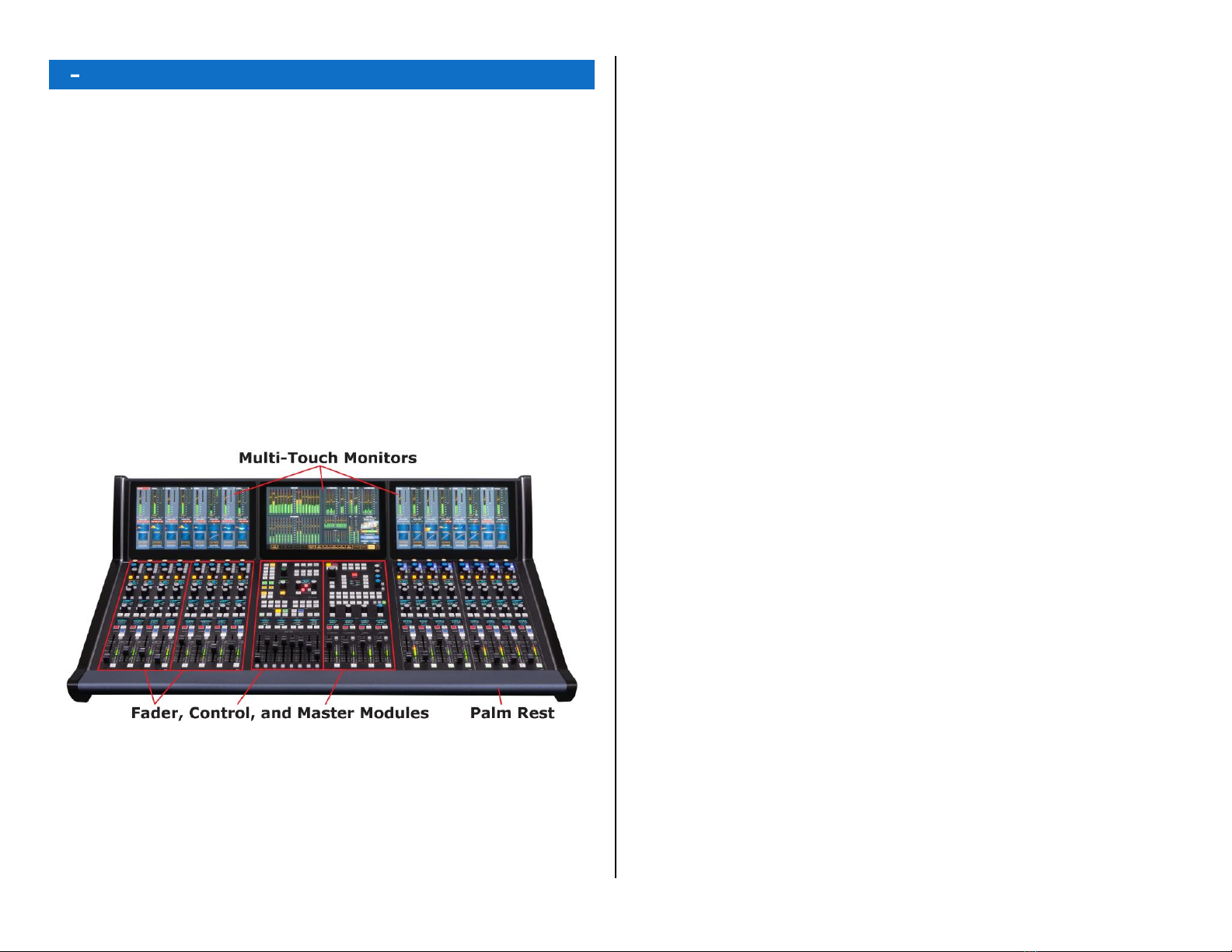

ARCUS OVERVIEW

Arcus is Wheatstone’s flagship television console. It incorporates the

same IP audio innovations as Wheatstone’s AoIP radio consoles and Blades

while maintaining the processing power found in our other TDM-based TV

consoles. Arcus is available in various frame sizes from the Arcus-16 with

sixteen channel faders on up to an Arcus-48 with forty-eight channel

faders. All this control power fits into a compact frame that’s only 46" (117

cm) wide frame for the Arcus-16, or 74" (188 cm) wide for the Arcus-32.

The console’s three main hardware components: Arcus Surface,

Gibraltar Mix Engine, and Surface Power Supply, along with the

optional Stagebox I/O Interface, are all FCC and CE certified.

The Arcus Surface is a compact audio-for-video controller. The fader

channel strips are mounted in Fader Modules which have four fader

channel strips. Each channel strip has a motorized fader, twenty control

buttons, six rotary encoders, and three color OLED displays. The channel

strip controls, along with the controls on the Master and Control Modules,

control the operation of the Gibraltar Mix Engine’s DSP, which contains the

Mixing and signal processing power for the Arcus’s input channels, Master

outputs, Submix groups, and VCA groups. EQ and Dynamics processing

are also available on every input channel along with monitoring controls

for the control room and three broadcast studios.

Designed for use in on-air studios, production suites, and remote

applications, the channel faders have ten layers of control, each with two

pages, to allow for control over even the most complex productions. One

can save and recall configurations for multiple shows and applications on

USB flash drives for instant console setup. All faders are motorized so their

physical positions quickly jump to their settings on each layer and page.

The Arcus integrates seamlessly with all major production automation

systems since it’s powered by Wheatstone’s award-winning WheatNet-IP

(WNIP) audio network, an AES67- and ST 2010-30-compatible IP audio

ecosystem, which allows for on-line Mixing, audio processing, and virtual

development tools including support for direct connection of SIP/VoIP and

codec appliances.

Arcus can access any resource connected to the facility’s WNIP network

using hardware fader channel controls or XY selector on the Control

Module, or thru software XY selectors on the main monitor. Since all Arcus

monitors are touchscreen, a row of intuitive View Select buttons along the

bottom of the main monitor allow one to quickly display various status and

control screens to adjust EQ and Dynamics, set up talkbacks, configure

Mix-minus feeds and bus matrices, assign mic muting and AutoMix group

control, and manage console sources and destinations.

Every fader channel has three OLED displays to show relevant channel

status and for user-set channel control functions. Another eleven OLED

displays on the Control and Master Modules show status and/or levels for

Aux, Sub Mix, or VCA groups, master outputs, monitor outputs, pane and

delay settings, source selection and levels, and talkback destinations.

Arcus’s I/O is entirely through the WNIP network so there are no

limitations regarding fixed connection points on the console chassis itself

since there are none! The Arcus Surface can access any source on the

network, and any channel can connect to any audio source or destination,

using any preferred audio format, at any time—regardless of whether it’s

HD/SDI, AES, MADI, AoIP, TDM, or analog. Unrestricted routing means

any source can be assigned to any channel, as needed. The days of having

to block out channels, based on input type, is a thing of the past, as is

having to repurpose inputs because of physical chassis limitations.

The Gibraltar Mix Engine can be mounted within the Mix room or in

any convenient rack within 330’(100 m) of the Arcus Surface (an optional

Fiber Interface allows for much longer connection distances). Two Mixer

Links (primary & secondary) connect the Surface to the Mix Engine. The

Mix Engine incorporates a WheatNet-IP (WNIP) interface, with a gigabit

Ethernet jack on a GBR card, to stream audio between the Arcus and the

other WNIP devices on the network.

The Mix Engine’s CPU includes DARS I/O to synchronize the Mix engine

with an in-house 48 kHz reference, although these days more often the

network will have a PTPv2 master clock, networked with the WNIP system,

to synchronize the Arcus to a 48 kHz sample rate to synchronize with your

video equipment and ST 2010-30- and AES67-compatible devices.

Each Arcus ships standard with a single output Surface Power Supply

(SPS-432), shown in Figure 1-3. It includes an IEC AC cord and a 16-foot

DC cable with locking connectors to connect the supply to the rear module

DC IN jack on the Arcus Surface.

The Arcus console ships with a factory default configuration so it can be

powered up and used straight out of the shipping crate. The default

settings are easily changed once the console is physical installed and

networked with one or more Wheatstone Blades or the Stagebox I/O

Interface to supply audio I/O for the console. The Arcus can then be

configured for use in a newsroom, production suite, remote van, sports

venue, or any number of other applications, using the two Windows PC

apps included with the console: Arcus Surface Setup and Navigator,