6WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

GB

2. Safety

2.1 Intended use

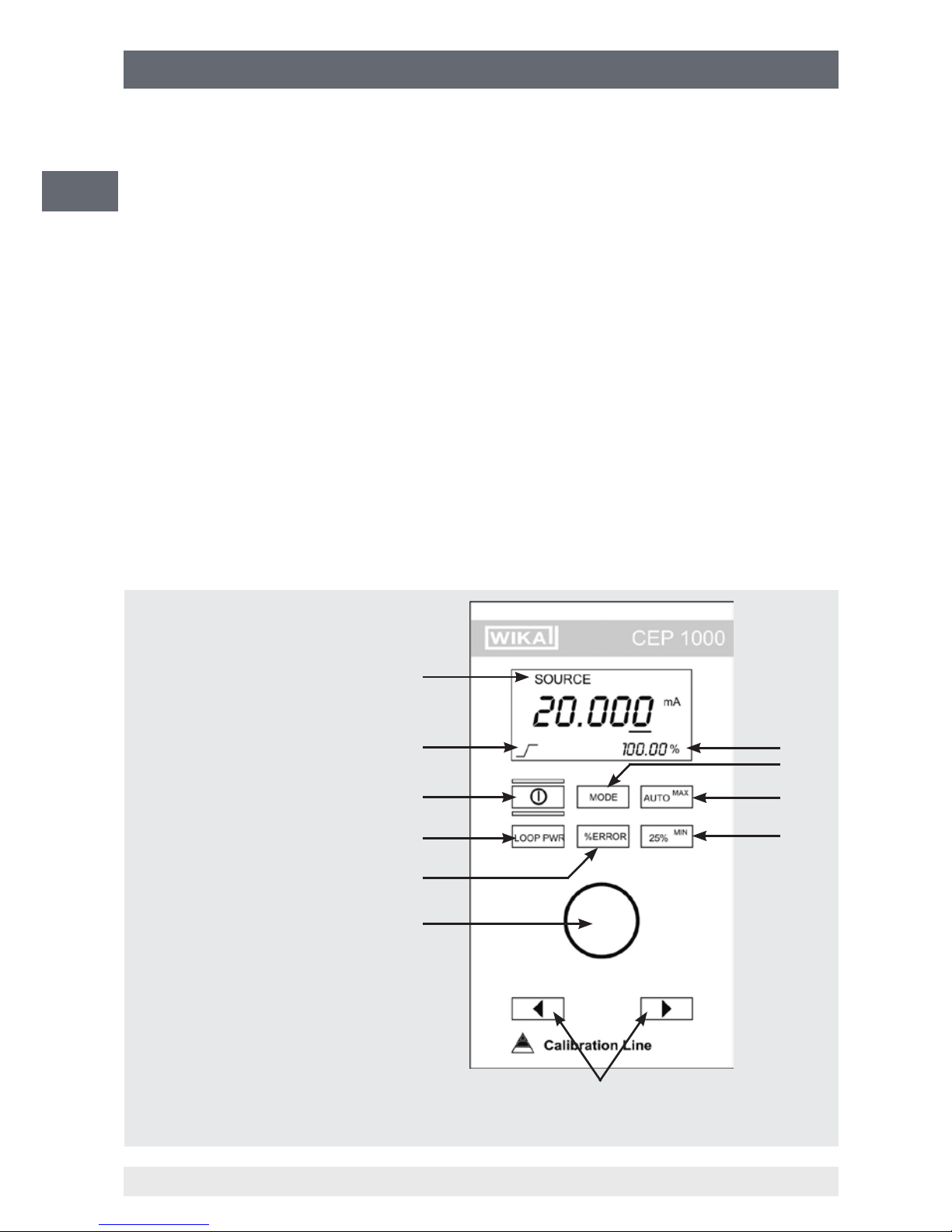

The precision loop calibrator CEP1000 is designed for high-accuracy measuring and

simulation of current and voltage.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be

observed. Should the instrument be improperly handled or operated outside of its

technical specications, it has to be taken out of service immediately and inspected by

an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in the instrument malfunctioning. Before putting it back into

operation, wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to

equipment.

■

The activities described in these operating instructions may only

be carried out by skilled personnel who have the qualications

described below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.