C

C

Co

o

on

n

nt

t

te

e

en

n

nt

t

ts

s

s

1General Information.........................................................................................................5

2Safety..............................................................................................................................7

2.1 Intended use....................................................................................................................7

2.2 Personnel qualification.....................................................................................................8

2.3 Additional safety instructions for instruments with ATEX approval...................................8

2.4 Special hazards...............................................................................................................9

2.5 Labelling / safety marks.................................................................................................11

2.5.1 Product label .................................................................................................................11

2.5.2 Explanation of symbols..................................................................................................11

3Specifications ................................................................................................................12

4Design and Function......................................................................................................14

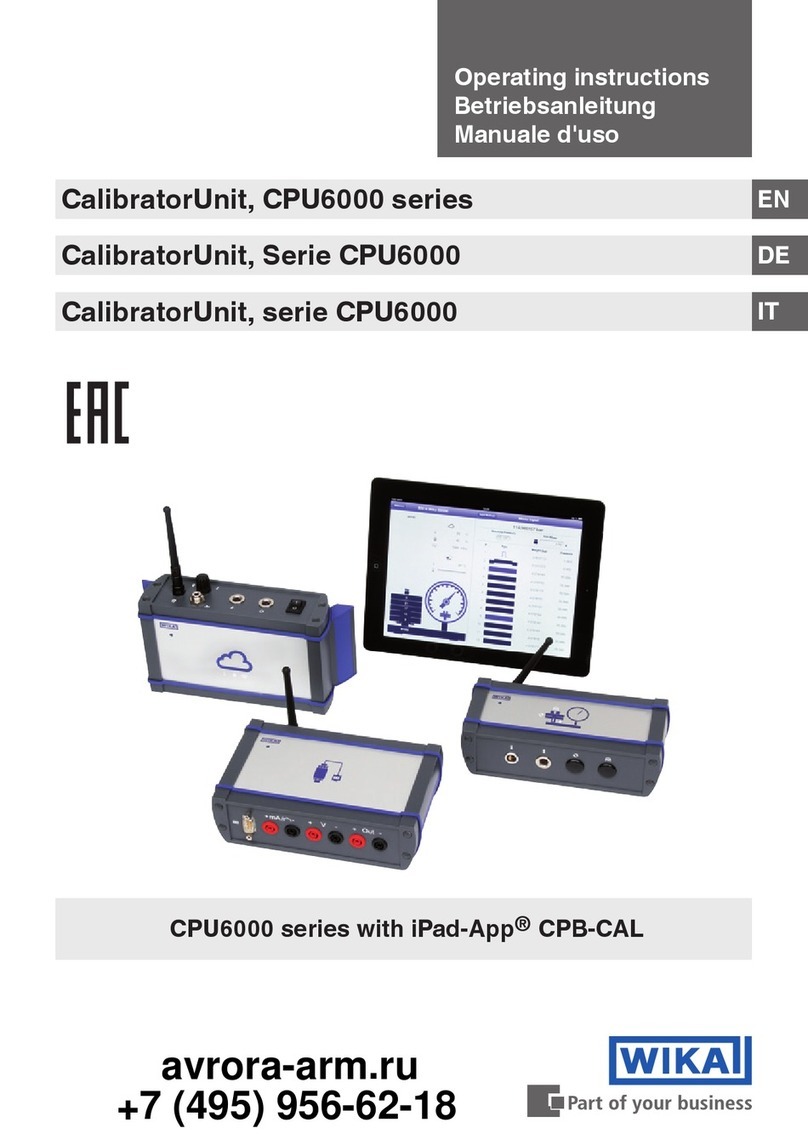

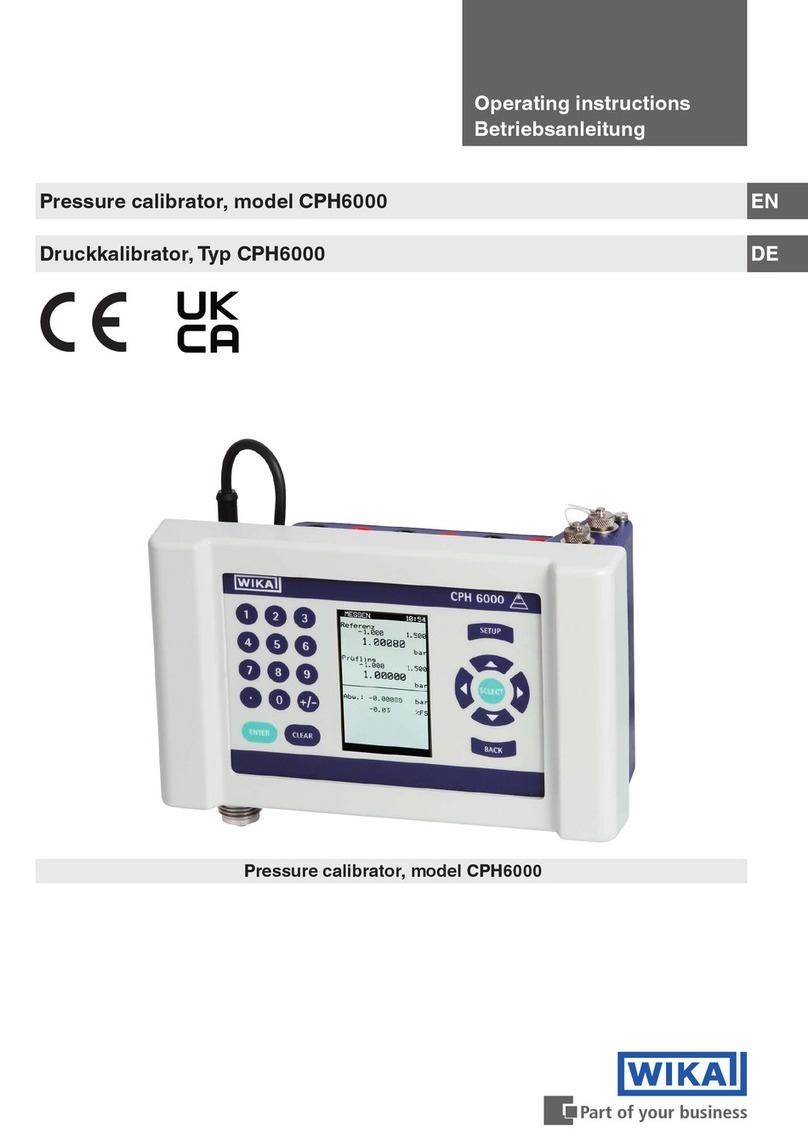

4.1 Short description / Description.......................................................................................14

4.2 Scope of delivery...........................................................................................................14

4.3 Pressure and electrical connections ..............................................................................15

4.4 Keypad..........................................................................................................................15

5Transport, packaging and storage .................................................................................16

5.1 Transport.......................................................................................................................16

5.2 Packaging......................................................................................................................16

5.3 Storage..........................................................................................................................16

6Commissioning, operation .............................................................................................17

6.1 Commissioning..............................................................................................................17

6.2 Calibrator display...........................................................................................................17

6.2.1 Main menu functionality.................................................................................................18

6.3 Using the backlighting....................................................................................................20

6.4 Using the "ZERO" function.............................................................................................20

6.4.1 Internal relative pressure sensor....................................................................................20

6.4.2 Internal absolute pressure sensor..................................................................................20

6.5 Other menu controlled functions....................................................................................21

6.5.1 Setting the contrast........................................................................................................21

6.5.2 Locking and unlocking configurations............................................................................21

6.5.3 Saving and recalling settings.........................................................................................22

6.5.4 Setting auto shut-off parameter .....................................................................................22

6.5.5 Activating and deactivating a display.............................................................................23

6.5.6 Low resolution function..................................................................................................23

6.5.7 Setting the resistance thermometer probe.....................................................................24

6.5.8 Damping / Average reading...........................................................................................24

6.6 Measuring pressure.......................................................................................................25

6.6.1 Media compatibility........................................................................................................25

6.7 Measuring current..........................................................................................................26

6.8 Measuring temperature with a resistance thermometer .................................................26

6.9 Performing a pressure switch test..................................................................................27

6.10 Calibrating transmitters..................................................................................................30

6.10.1 Using the mA measurement function.............................................................................30

6.10.2 Calibrating a pressure-to-current transmitter..................................................................30

6.10.3 “%-Error” function..........................................................................................................31

6.11 “MIN/MAX” value capture ..............................................................................................33

6.12 Factory settings.............................................................................................................34

6.13 Flow calibration..............................................................................................................35

7Maintenance, cleaning and servicing.............................................................................36

7.1 Maintenance..................................................................................................................36

7.2 Replacing batteries........................................................................................................36