Contents

Contents

1. General information 5

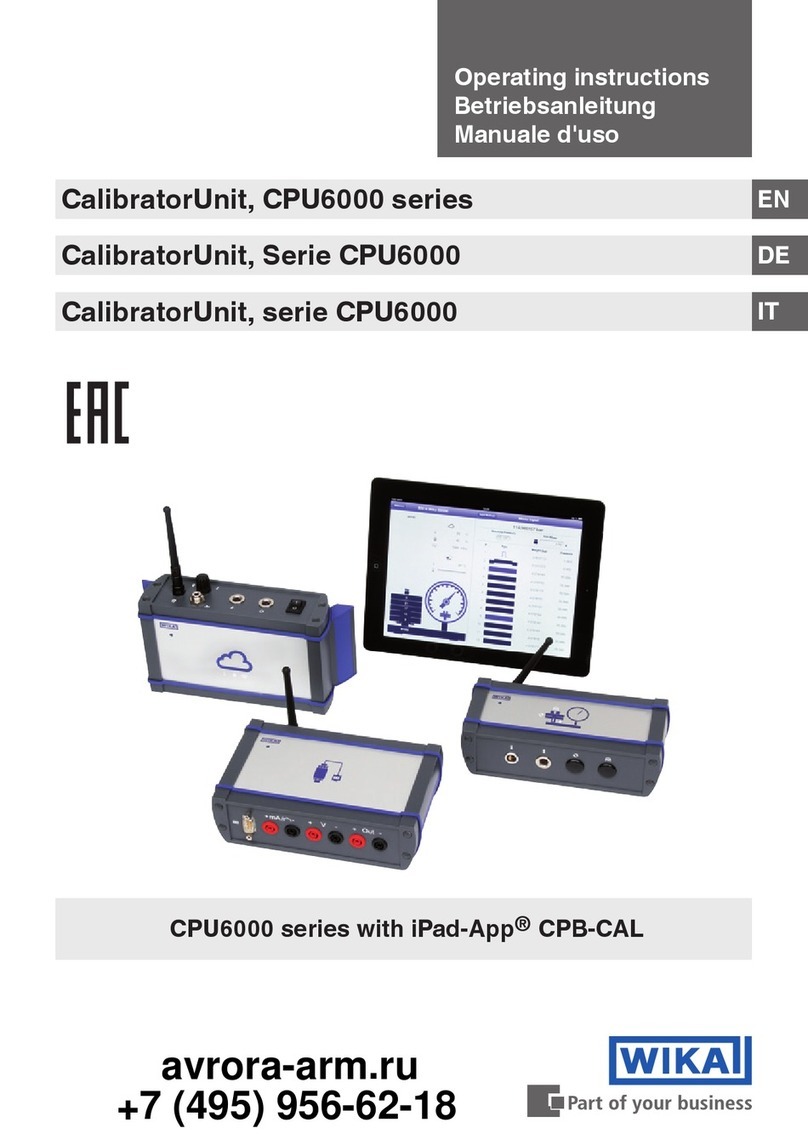

2. Short overview 6

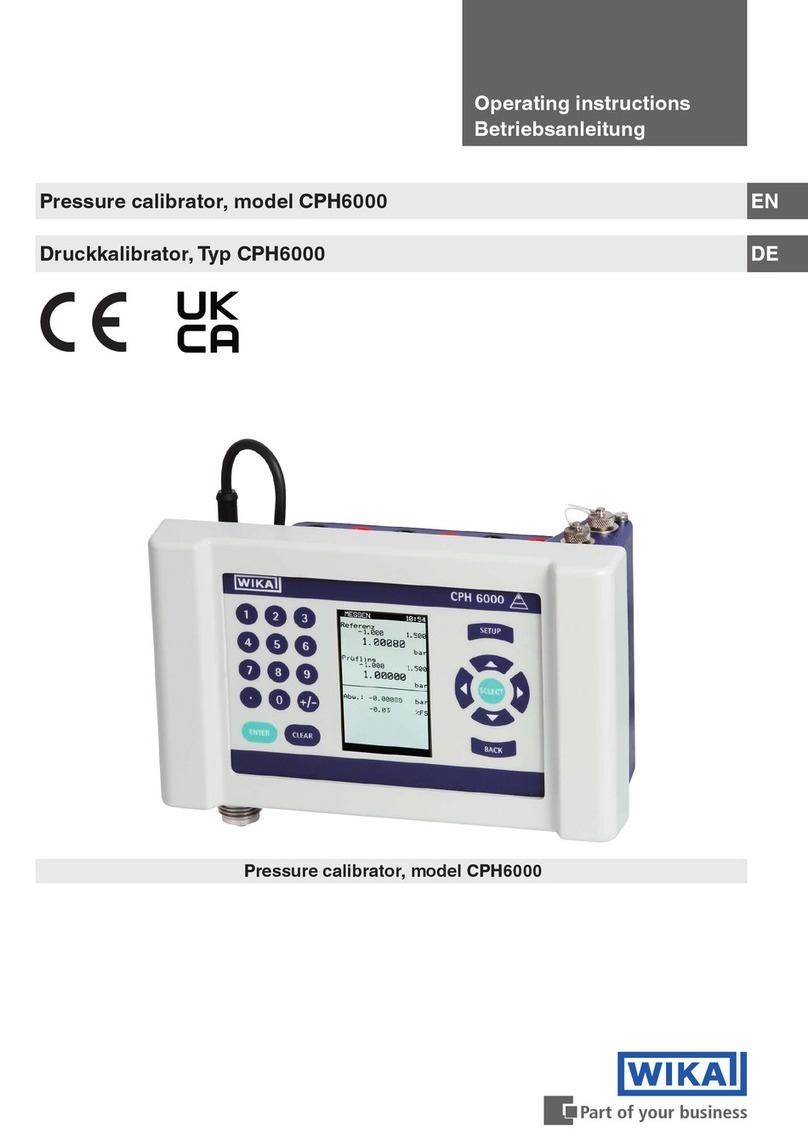

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . 7

3. Safety 8

3.1 Explanation of symbols. . . . . . . . . . . . . . . . . . . . 8

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Responsibility of the operator. . . . . . . . . . . . . . . . . . 9

3.5 Personnel qualification . . . . . . . . . . . . . . . . . . . . 10

3.6 Labelling, safety marks . . . . . . . . . . . . . . . . . . . . 10

4. Design and function 11

4.1 Front foil . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.1 Connections . . . . . . . . . . . . . . . . . . . . . . 12

4.1.2 Key function . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Batteries. . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Selecting the batteries or rechargeable batteries . . . . . . . . . 14

4.2.2 Using the power supply unit . . . . . . . . . . . . . . . . 14

5. Transport, packaging and storage 15

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Packaging and storage . . . . . . . . . . . . . . . . . . . . 15

6. Commissioning, operation 16

6.1 Main display . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Menu bar . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.1 “Measuring” menu function . . . . . . . . . . . . . . . . . 18

6.2.2 “Output” menu function . . . . . . . . . . . . . . . . . . 19

6.2.3 “Pulse output” menu function . . . . . . . . . . . . . . . . 19

6.2.4 “UPPER”, “LOWER” and “MORE” menu function . . . . . . . . . 19

6.2.5 “Documentation” menu function . . . . . . . . . . . . . . . 20

6.2.6 “Automatic output function” menu function. . . . . . . . . . . . 20

6.2.7 “Frequency or pulse output” menu function . . . . . . . . . . . 20

6.2.8 “Contrast” menu function . . . . . . . . . . . . . . . . . 20

6.2.9 “Automatic switch-off” menu function . . . . . . . . . . . . . 21

6.2.10 “Time” menu function . . . . . . . . . . . . . . . . . . . 21

6.2.11 “Probe-specific coefficients” menu function . . . . . . . . . . . 21

6.2.12 “ZERO” menu function . . . . . . . . . . . . . . . . . . 22

6.2.13 “Terminal emulation” menu function . . . . . . . . . . . . . . 22

6.2.14 “Parameter selection” menu function . . . . . . . . . . . . . 22

6.3 Cursor control/set-point control . . . . . . . . . . . . . . . . . 22

6.4 Using the measuring modes (lower display) . . . . . . . . . . . . . 23