1GENERAL INFORMATION..................................................................................................5

2SAFETY...............................................................................................................................6

2.1 Explanation of symbols.......................................................................................................................... 6

2.2 Intended use.......................................................................................................................................... 7

2.3 Personnel qualification........................................................................................................................... 7

2.4 Additional safety instructions for instruments with ATEX approval only CPH8000/IS -ET/IS............... 8

2.5 Special hazards ..................................................................................................................................... 9

2.6 Labelling / safety marks....................................................................................................................... 10

3SPECIFICATIONS .............................................................................................................11

3.1 Base instrument................................................................................................................................... 11

3.2 Certificates........................................................................................................................................... 12

3.3 Pressure module.................................................................................................................................. 12

3.3.1 Internal sensors................................................................................................................................ 12

3.3.2 External pressure sensor CPT8100................................................................................................. 13

3.4 Electrical signals.................................................................................................................................. 14

3.4.1 Electrical input signals...................................................................................................................... 14

3.4.2 Electrical output signals ................................................................................................................... 14

3.4.3 HART module................................................................................................................................... 15

3.5 Resistance thermometer measurement .............................................................................................. 16

3.6 Resistance thermometer simulation .................................................................................................... 17

3.7 Thermocouple measurement............................................................................................................... 18

3.8 Thermocouple simulation..................................................................................................................... 18

3.9 Environmental parameters module...................................................................................................... 19

3.10 CPH8000 –IS Dimension in mm (in)................................................................................................... 20

3.10.1 Case for instrument model CPH8000 - /IS....................................................................................... 20

3.10.2 Front panel of model CPH8000 - /IS................................................................................................ 20

3.10.3 Case for instrument model CPH8000ET - ET/IS ............................................................................. 21

3.10.4 Front panel of model CPH8000 ET - ET/IS...................................................................................... 21

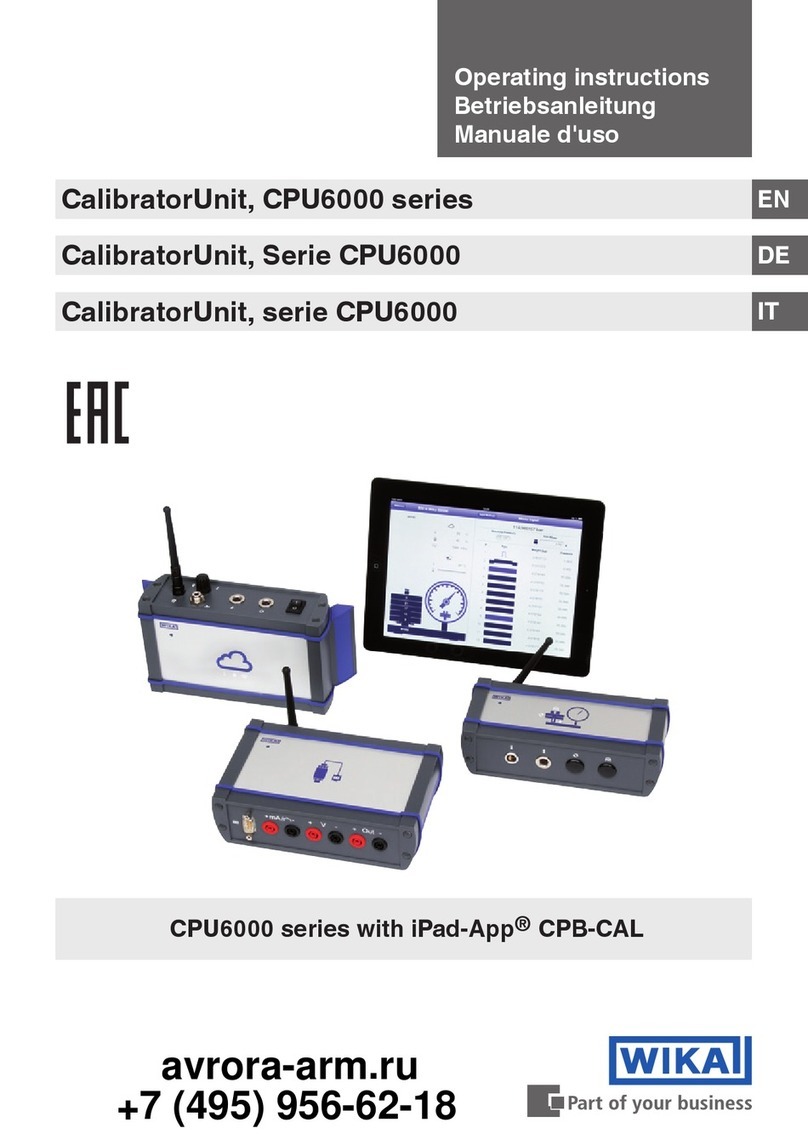

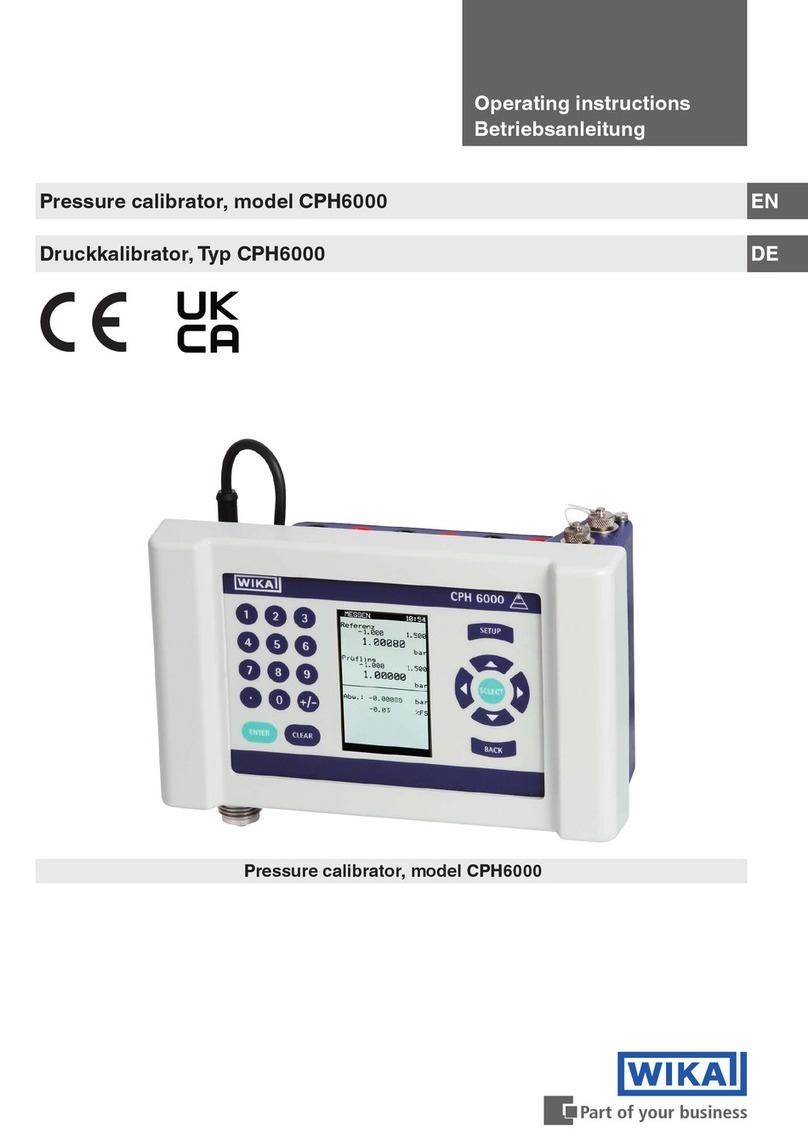

4DESIGN AND FUNCTION .................................................................................................22

4.1 Description........................................................................................................................................... 22

4.2 Scope of delivery ................................................................................................................................. 24

4.3 Power supply ....................................................................................................................................... 24

4.3.1 Smart Power Supply & Battery Charger model 212009................................................................... 24

4.3.2 Safety instruction.............................................................................................................................. 25

4.3.3 Liability Disclaimer............................................................................................................................ 25

4.3.4 LED status Functionalities................................................................................................................ 25

4.3.5 Operating the device........................................................................................................................ 26

4.3.6 Care and Maintenance..................................................................................................................... 26

4.3.7 Technical Specifications................................................................................................................... 26

5TRANSPORT, PACKAGING AND STORAGE ..................................................................27

5.1 Trasport................................................................................................................................................ 27

5.2 Packaging............................................................................................................................................ 27

5.3 Storage ................................................................................................................................................ 27

6COMMISSIONING, OPERATION ......................................................................................28

6.1 Commissioning .................................................................................................................................... 28

6.1.1 Instrument overview CPH8000 - /IS................................................................................................. 28

6.1.2 Instrument overview CPH8000ET - ET/IS........................................................................................ 29

6.1.3 Functional Modules.......................................................................................................................... 30

6.1.3.1 Input module for electrical/temperature signals............................................................................... 30

6.1.3.2 Output module for electrical/temperature signals............................................................................ 30

6.1.3.3 Pressure module.............................................................................................................................. 30

6.1.3.4 HART module .................................................................................................................................. 31

6.1.3.5 Environmental parameters module (optional).................................................................................. 33

6.2 Pressure............................................................................................................................................... 33

6.2.1 Pneumatic circuit CPH8000 - /IS (not avaiilable for CPH8000ET- ET/IS)....................................... 33

6.3 Electrical section.................................................................................................................................. 35

6.3.1 Misure segnali elettrici...................................................................................................................... 35