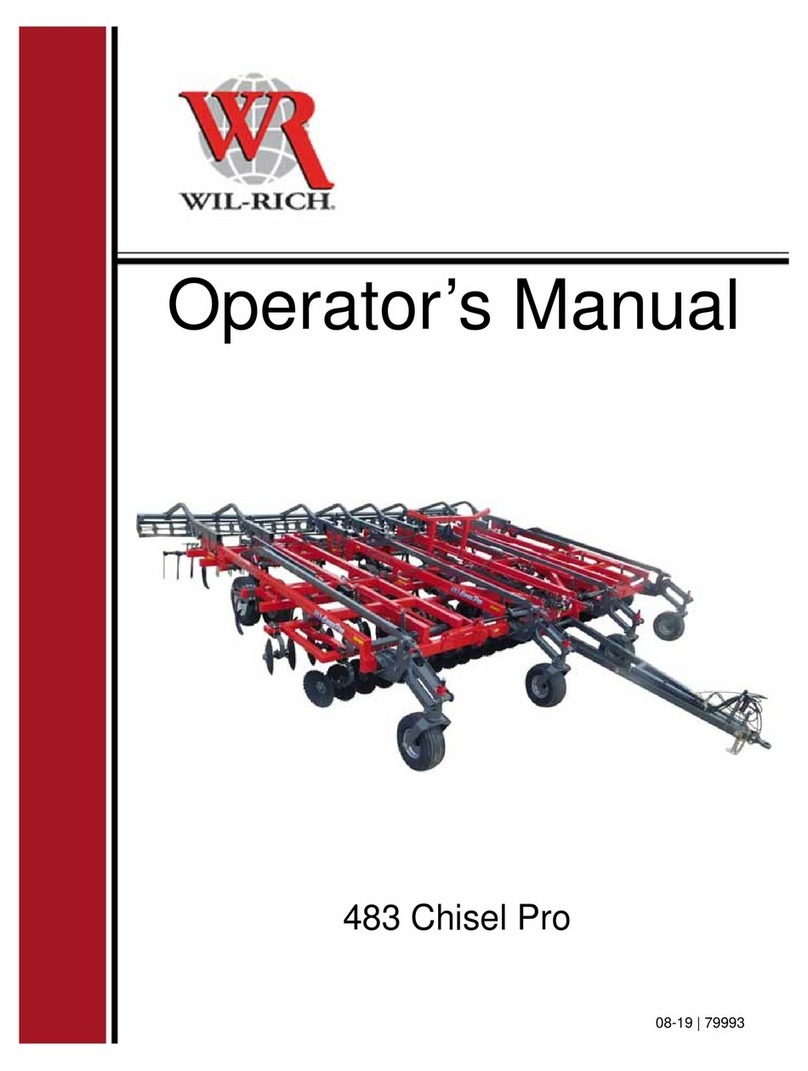

RIGID (16’ & 19’) 483 CHISEL PRO

1. Assembly

Assembly Introduction ............................................................................................................. 5

Main Axle Assembly .................................................................................................................. 8

Shank Assembly......................................................................................................................... 9

16’Shank Frame Layout ........................................................................................................ 10

19’ Shank Frame Layout........................................................................................................ 11

Gang and Axle Spacing.......................................................................................................... 12

Main Frame Assembly to Shank Frames.......................................................................... 13

Main Frame Assembly to Axle and Disc Frames............................................................ 14

Hitch Assembly ......................................................................................................................... 15

Manual Holder Assembly....................................................................................................... 17

Gauge Wheel Assembly......................................................................................................... 18

Gauge Wheel Spindle & Tire Assembly ............................................................................ 19

Disc Lift Assembly.................................................................................................................... 20

Adjust Arm Assembly .............................................................................................................. 21

Single Point Depth Control .................................................................................................... 22

Main Frame Shank Stub Assembly .................................................................................... 23

Main Lift Hydraulics ................................................................................................................. 24

Disc Lift Hydraulics .................................................................................................................. 25

Safety Light Assembly ............................................................................................................ 26

Branding Decal Layout ........................................................................................................... 27

Chrome Straight Spike Assembly........................................................................................ 28

Straight Spike Assembly ........................................................................................................ 29

Concave Twist Spike Assembly........................................................................................... 30

16’ Twisted Spike Layout....................................................................................................... 31

19’ Twisted Spike Layout....................................................................................................... 32

General Information

Orientation:

Any reference to left (L) or right (R) sides or components is to

be understood as being viewed from behind the implement and

looking forward.

Serial Number Break:

Every Implement has a serial number located on the body of

the frame. These serial numbers are consecutively assigned to

the implements as they are manufactured. To aid in part

ordering, we reference the serial number at the point the

change occurred to provide and accurate means of

determining proper parts.

P357194 – CHASIS GREY

SPRAY CAN

P351481 – RED PAINT

SPRAY CAN

P240799 – 460EP

GREASE