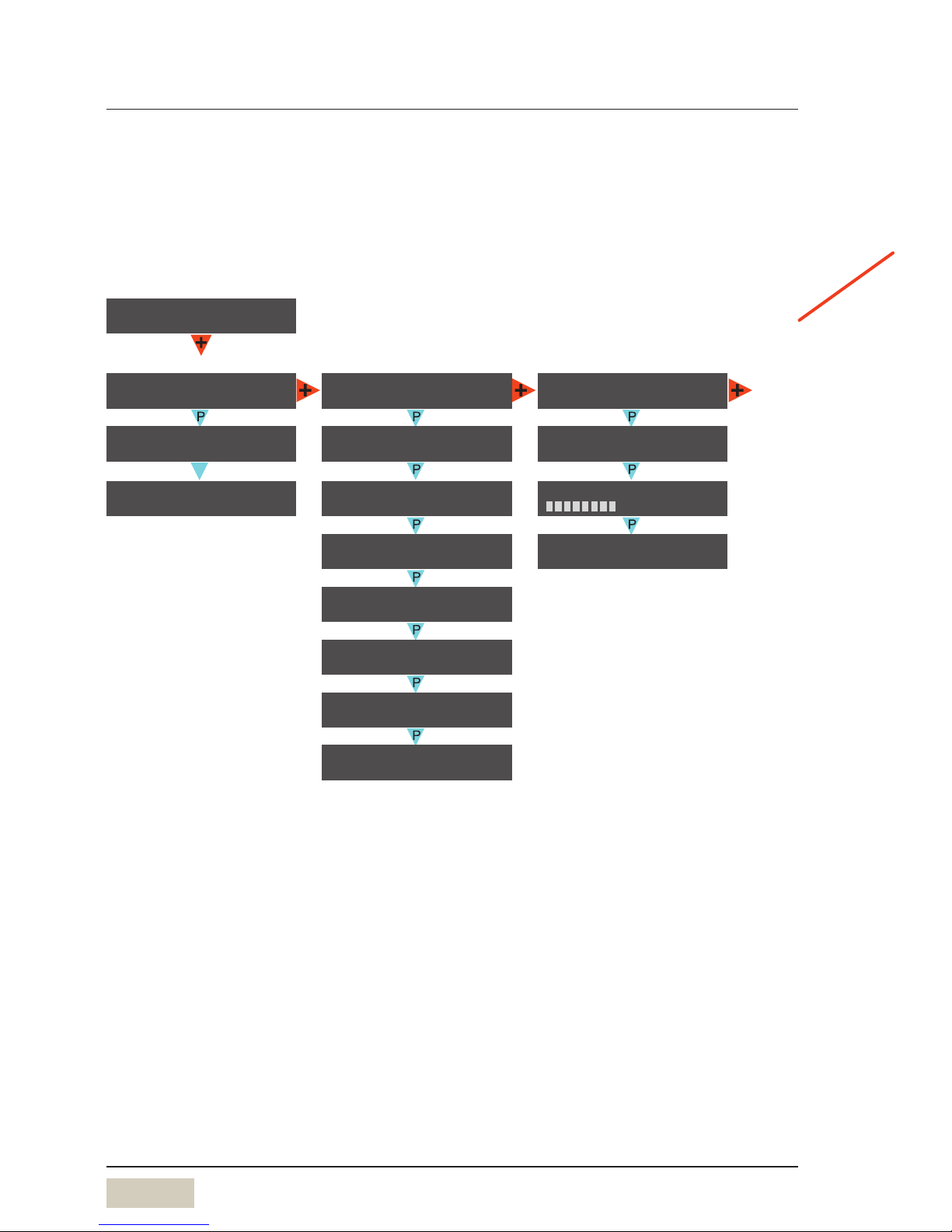

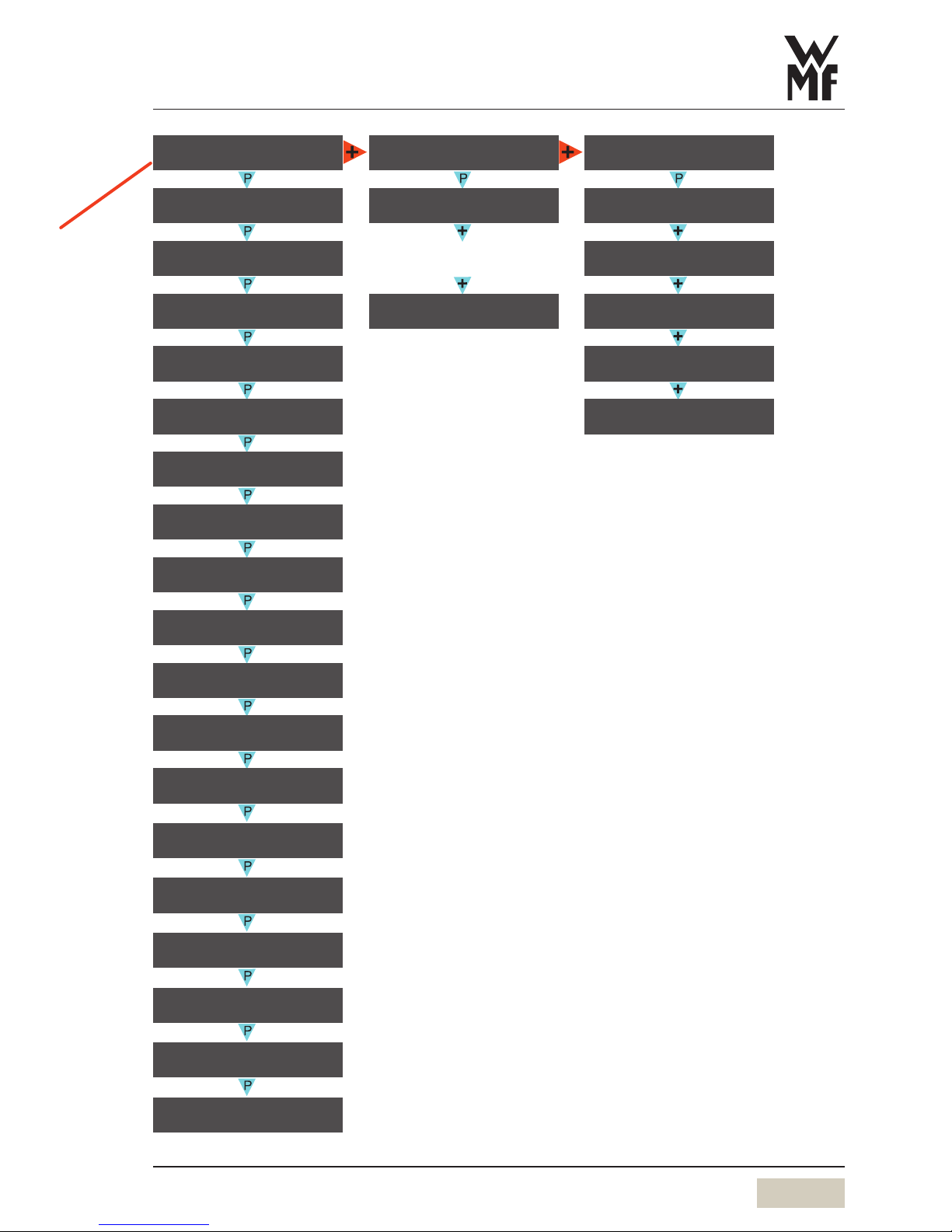

1 Initial operation

During the initial operation the steam boiler respectively

the hot water boiler is filled automatically according to the

procedure described as follows.

Machines with steam boiler and hot water boiler:

The steam boiler is filled from the hot water boiler via the

steam boiler supply valve. The steam boiler supply valve is

opened until the steam boiler electrode is contacted. Then

the machine is heated up.

Machines with only hot water boiler:

As the level of these machines can not be detected, the

hot water boiler is filled for 300 s. The waste water is led

into the drip tray via the release valve. If the first filling

up is interrupted, it will be restarted by switching ON the

machine.

Condition

Machine is reset to customer setup

Perform the display-guided setup.

The following is set:

• language, switch off time, time, date

• filter capacity, replacement mode (customer or

service)

• self-service mode

If necessary update software to latest version

(Servicetool required)

Perform portioner calibration (Servicetool required)

Adjust boiler temperature and beverages according to

customer specifications

Afterwards a test brewing is made

Before regular operation:

rinse the pipes, dispense three cups of hot water

perform the cleaning cycle

After setup, the service technician must note the

following statement in the assembly invoice:

“At the end of operation, had to be turned off at source.

The user manual and accessories were given to the

customer.”

The customer must acknowledge this by his signature.