µ

WMF coffeemachines

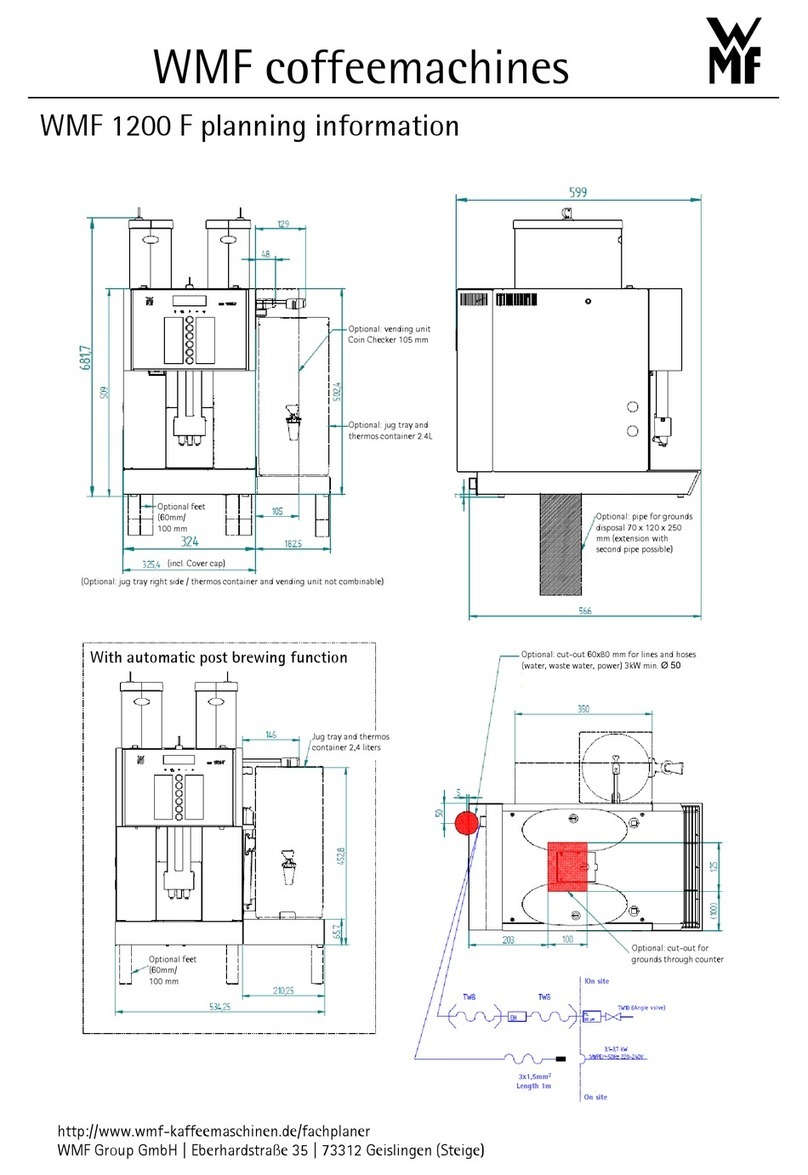

WMF 1500 S planning information –Dynamic Milk

Ventilation If ventilation possibility is limited sufficient ventilation need to be provided e.g machine on feet

extension, active ventilation, additional ventilation slots/ openings in counter area. Ventilation

slots must not be covered. Under certain circumstances a forced ventilation on site is necessary

to ensure heat dissipation.

Electrical

connection

These specifications for the electrical connection and the standards quoted apply for connecting

the coffee machine in EU countries. It may be necessary to also observe additional country-

specific regulations. Outside the EU countries acceptance of the standards quoted is to be

checked by the legal entity or natural person who wishes to use the coffee machine.

The local power supply must be constructed according to the currently valid IEC 364 (DIN VDE

0100). An isolated ground socket or a country-specific single-phase socket for single-phase

connection, or a 5-pole CEE / CEKON socket per EN 60309 or a country-specific multi-pole

socket for a three-phase connection, must be available near the machine. The sockets are part of

the customer‘s on-site installation.

The mains cable must not come into contact with hot surfaces. If the mains cable for this device

is damaged then it must be replaced by our service

personnel or a similarly qualified person, in order to prevent hazards.

In order to avoid possible faults from arising on our shielded data lines due to potential

equalisation currents between the devices, an additional potential equalisation unit should be

planned for devices connected to the vending system. (See EN 60309)

Water

supply and

drainage

The water supply must be located close to the machine (max. distance 800 mm). An anytime

easily accessible and sufficiently dimensioned water tap (preferably ball tap) as well as a dirt

filter with mesh size 0,080 mm must be installed below the counter in the water supply.

For connection from below through the counter a cut-out must be made in the hatched area

on-site according to drawing (see top view).

For drinking water with carbonate hardness above 5°dKH (carbonate hardness), a WMF water

filter should be fitted upstream.

If the coffee machine is connected to a drain connection, a funnel siphon must be installed in

the drain pipe.

Please observe that the free drain (funnel siphon with sheet metal angle) is fitted vertically. This

means that it must always be vertical to the water back pressure level that is reached. It must be

fitted in a way that the given gradient of the drain hoses (2%) is observed.

Additionally, the free drain must always be below the drains of the coffee machine and above

the actual drain pipe connections (HT40, HT50 or similar) with respect to its height.

To a funnel siphon with sheet metal angle max. two coffee machines with DN19 hose and black

silicone fabric hose should be connected. Other devices (dishwasher, sink etc.) should be installed

elsewhere.

The free drain incl. hoses must not be exposed to heavy tensile, pressure or torsional load.

Hereby, damage might be caused at the mechanical components of the free drain. Consequently,

its usability may get lost.

The on-site preliminary works for the drainage connection must be commissioned by the

operator of the machine. They must be carried out by concession plumbers in compliance with

the prevailing, national as well as local regulations.

The following drawings serve to illustrate the drains and do not include any other connections,

such as power or water infeed!

http://www.wmf-kaffeemaschinen.de/fachplaner

WMF Group GmbH | Eberhardstraße 35 |73312 Geislingen (Steige)