Table of contents 4

Table of contents

Preface...................................................................................................................................................................................................................................................... 2

Change history......................................................................................................................................................................................................................................... 3

Table of contents .................................................................................................................................................................................................................................... 4

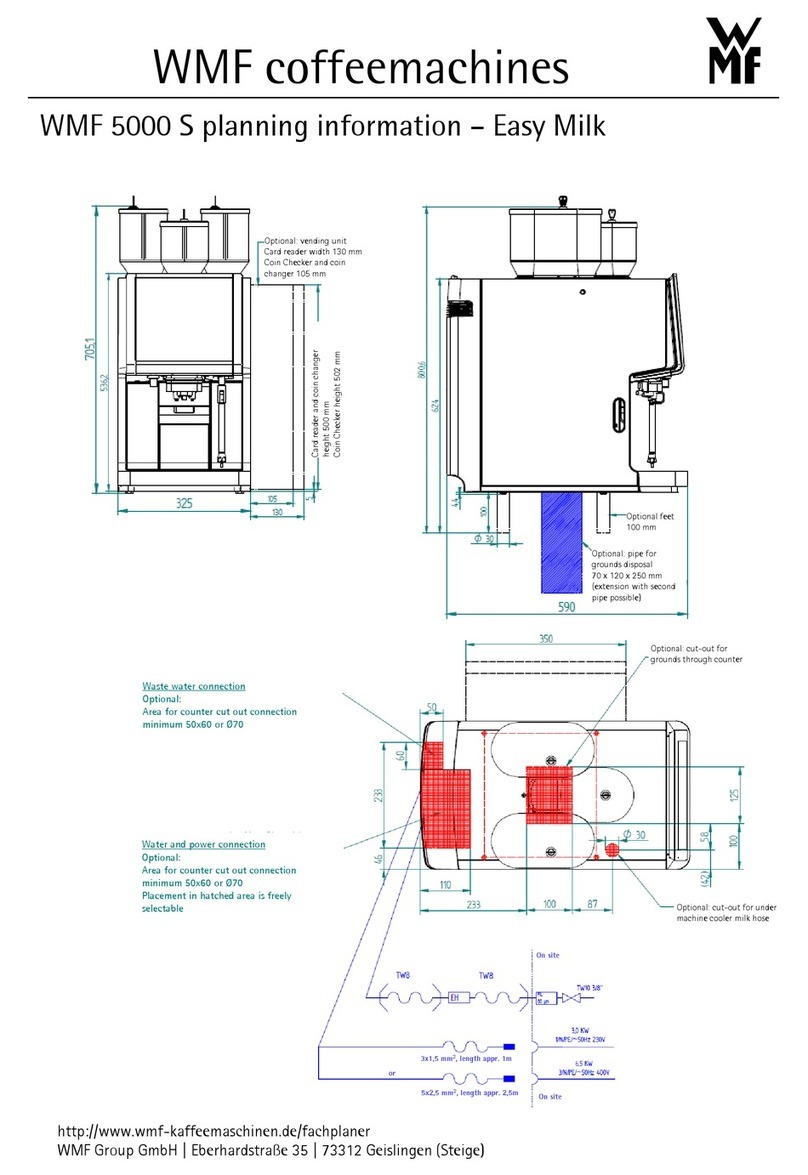

1Installation and commissioning................................................................................................................................................................................................ 6

1.1 Customer’s on-site connection requirements.........................................................................................................................................................................................................6

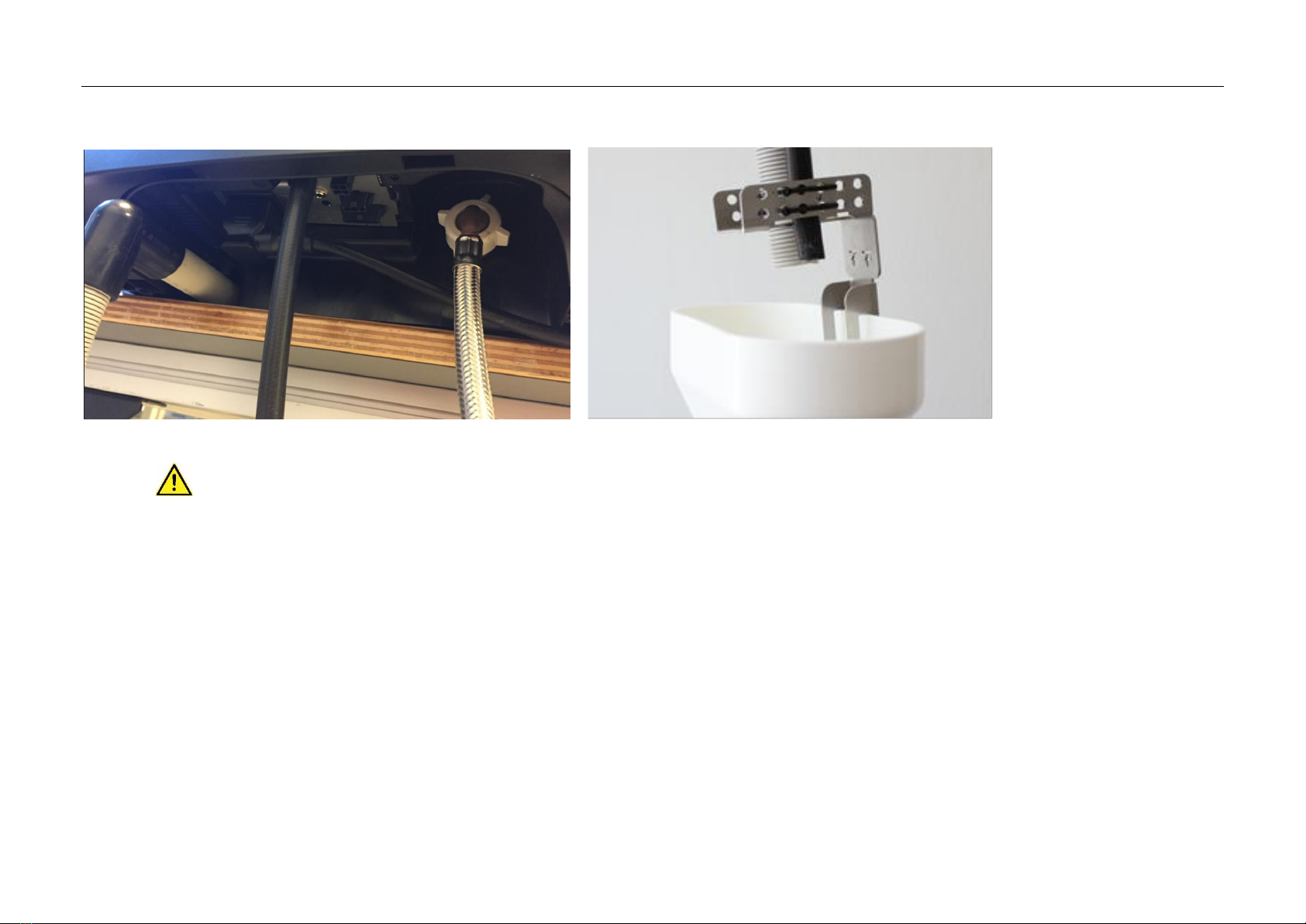

1.2 Hardware connection and preparatory work..........................................................................................................................................................................................................6

1.2.1 General activities.............................................................................................................................................................................................................................................................6

1.2.2 Recommended water filter...........................................................................................................................................................................................................................................8

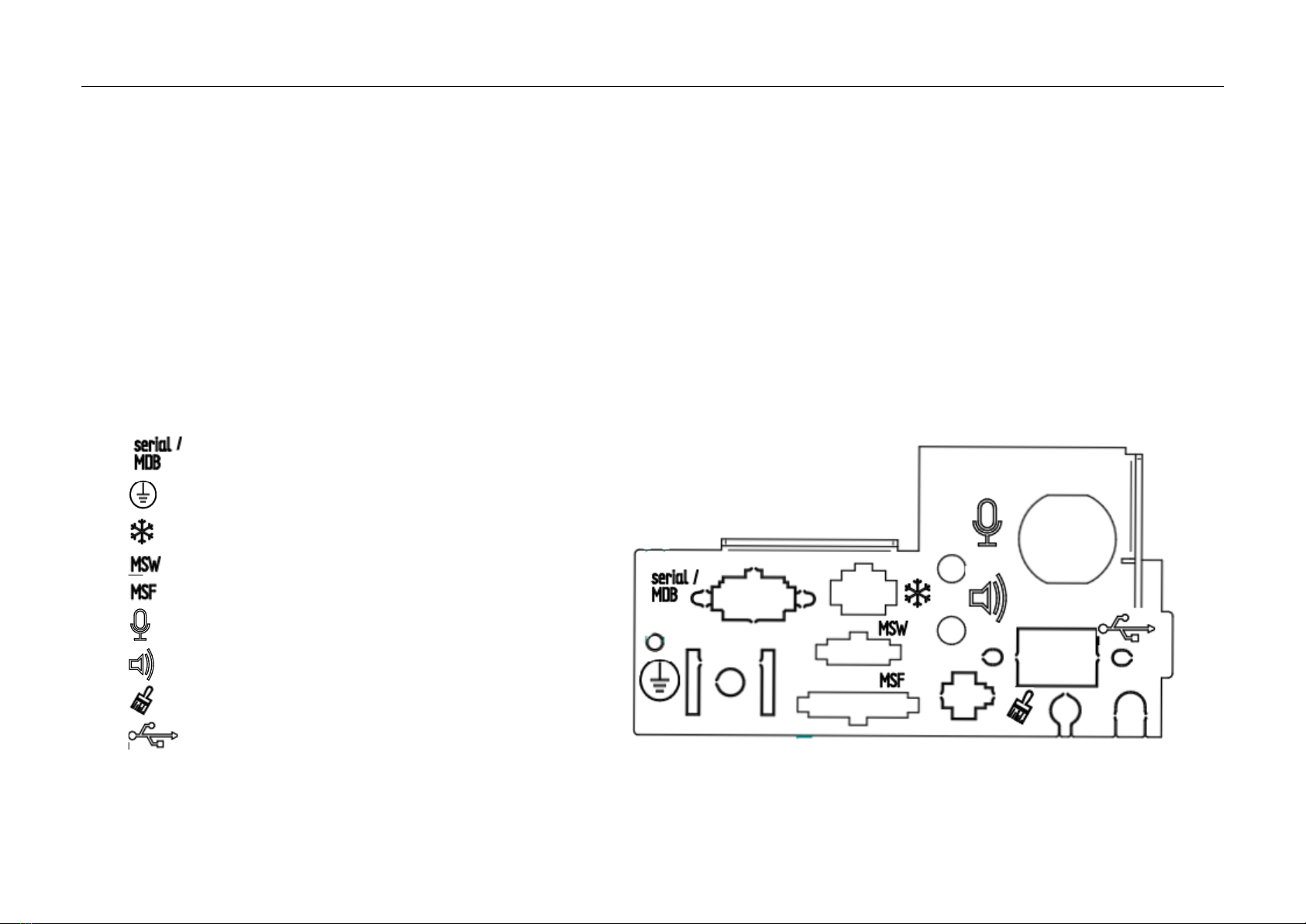

1.2.3 Interface plate for electrical connections................................................................................................................................................................................................................8

1.3 Initial commissioning.....................................................................................................................................................................................................................................................9

1.3.1 Goal of the Technician's Intro.....................................................................................................................................................................................................................................9

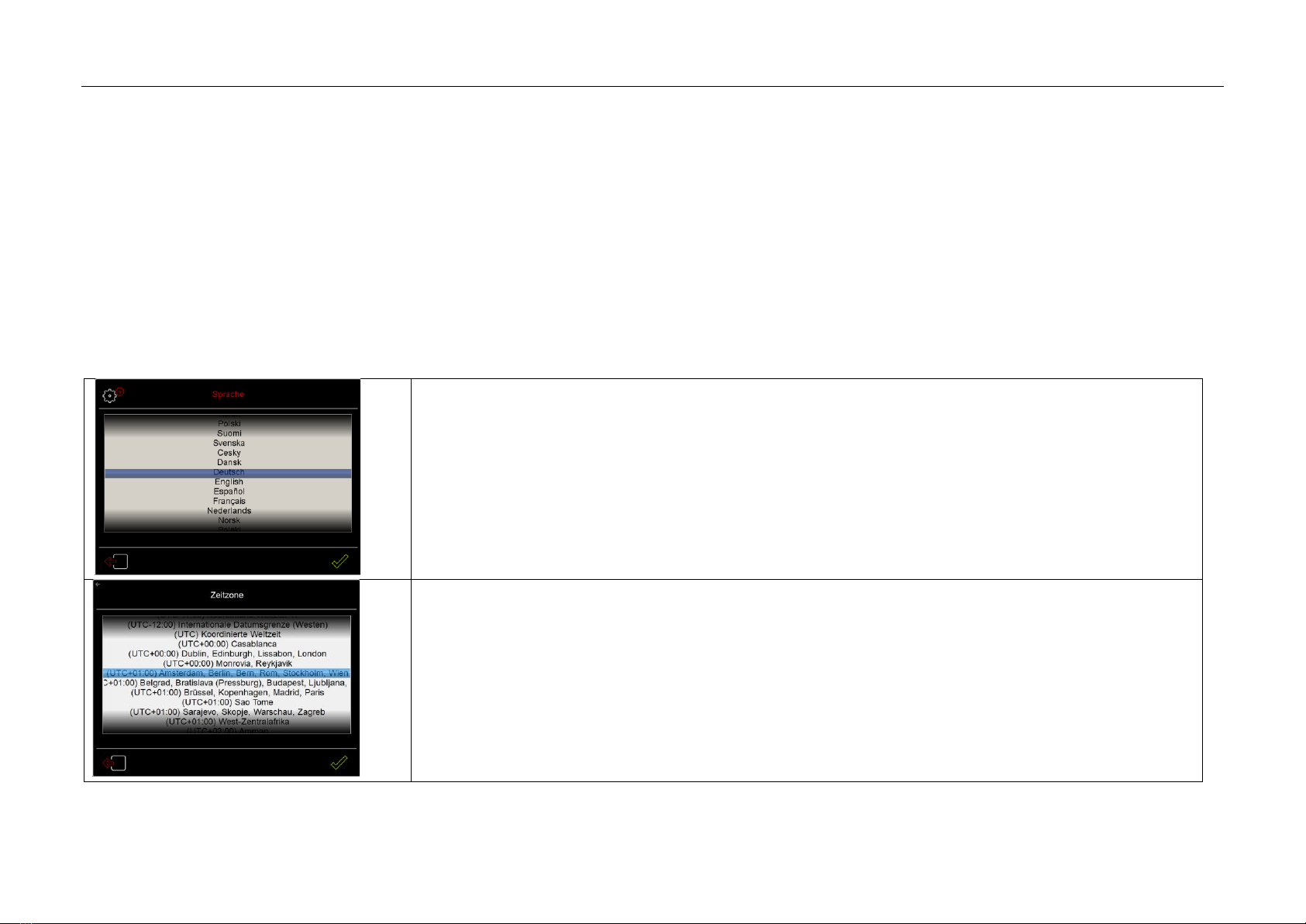

1.3.2 Workflow, Technician's Intro .......................................................................................................................................................................................................................................9

2Service........................................................................................................................................................................................................................................13

2.1 Brewer ..............................................................................................................................................................................................................................................................................13

2.2 Distance between angle sensor and brewer spindle (magnet) ........................................................................................................................................................................14

2.3 Espresso pump................................................................................................................................................................................................................................................................15

2.4 Grinders............................................................................................................................................................................................................................................................................16

2.4.1 Mechanical basic settings...........................................................................................................................................................................................................................................16

2.4.2 Using the electrical grinding degree setting on the grinder............................................................................................................................................................................16

2.4.3 Portioner calibration....................................................................................................................................................................................................................................................17

2.4.4 Grinder(s) idle current calibration............................................................................................................................................................................................................................18