if „no“ is activated: no access to component test, service routines and

counter.

if „yes“ is activated: customer check-up can be performed.

if „yes“ is activated: water filter can be exchanged and rinsed.

If activated („yes“), the key operator is able to

• do the descaling (turbo descaling)

• carry out and reset the customer check-up

• exchange and rinse the scale filter

• access the component test

• access the service routines

• access the counters

Maintenance messages in Key Operator mode

Customer check-up

Maintenance after 1 year or 15,000 brewings

Tasks to be performed analogy to customer check-up

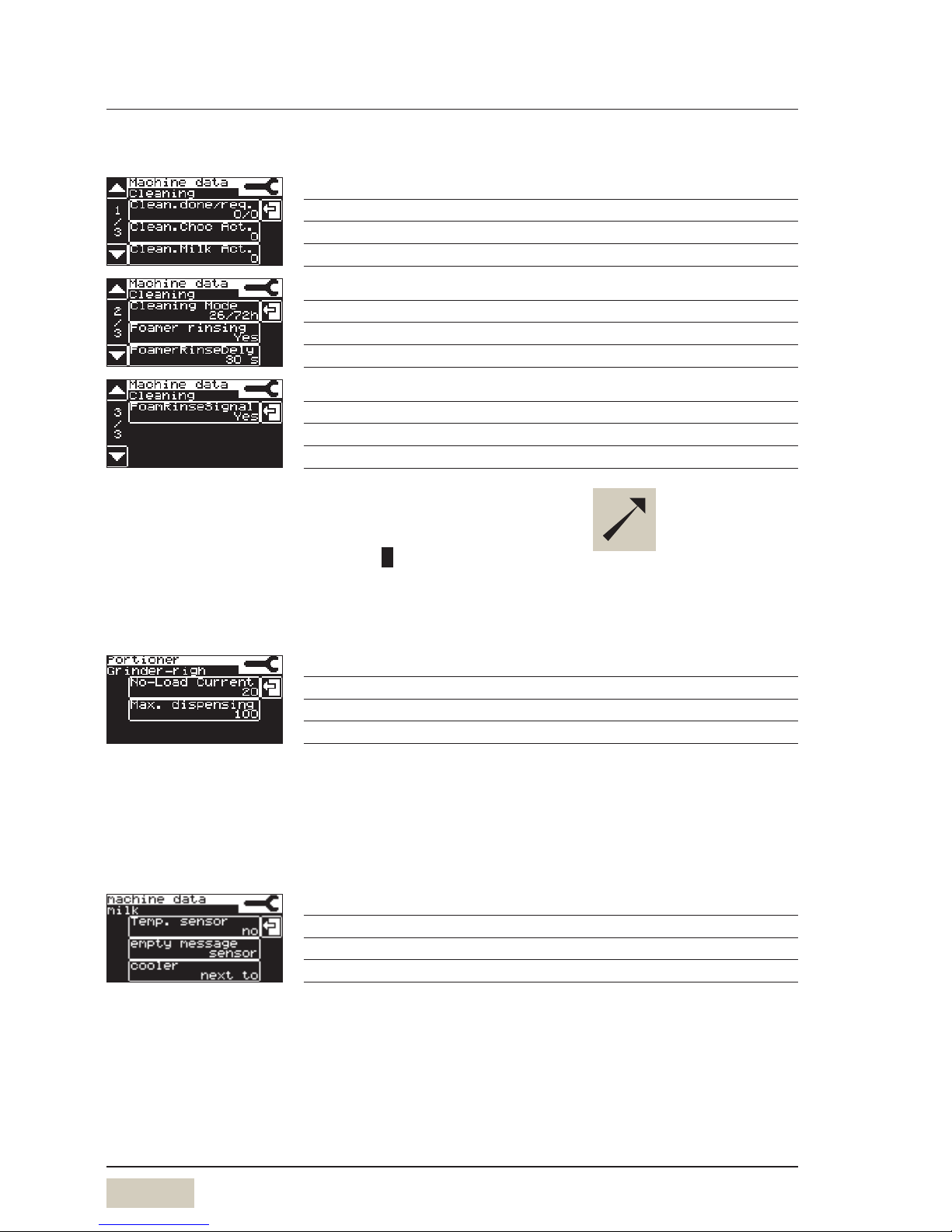

3.10 Submenu standards factoryservice/

customer

After tapping “self-detect” is first run automatically. All

components operating on 24 V or 30 V are automatically

addressed. The components are automatically identified.

During self-detect the grounds container must be in

place, the adjustable screen closed or the 24/30 V circuits

of the components are interrupted.

Factoryservice/customer menu 1

Configuration of grinders

Configuration of powder portioner

Heating capacity

Configuration of grinders is registered automatically (see

chapter portioner).

Configuration of powder portioner is registered

automatically (see chapter portioner).

Heating capacity can be changed as required.

Reset with C on display see

machine data service date

Customer check-up

or Menu Care Customer

check-up

See chapter engineering, portioner

in the training manual