7

An ongoing program of product improvement may require us to change

specifications without notice. FD-6045-CE, FD-8645-CE,

Revised November 2015. Doc no: M0042.04

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Tel +1.360.650.1111

Fax +1.360.650.1166

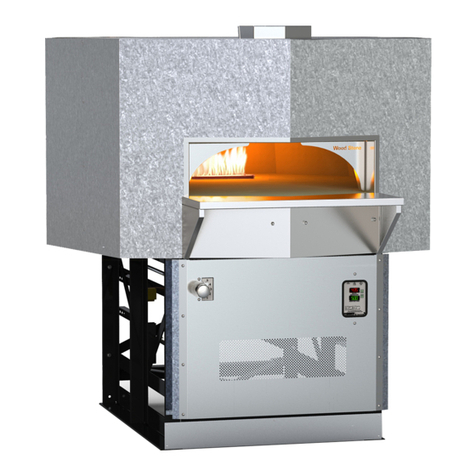

FD-6045-CE & FD-8645-CE Fire Deck Oven

Installation and Operation Manual

OVEN VENTING

Wood Stone ovens should be vented in accordance with pertinent national, regional and local codes concerning Type A

appliances; check venting plans with the authority having jurisdiction before proceeding with installation.

The above statement taking precedence, Wood Stone Corporation recommends the following:

Wood Stone gas-fired ovens must be vented using an approved exhaust hood� All ducting (whether insulated or not) used in

exhaust systems venting Wood Stone ovens should meet the construction requirements of a grease duct. Take care to maintain

proper clearances from the duct to combustible construction�

Fire Deck model numbers containing a “-W” (other than the first letter of the model number) should be vented in accordance

with codes concerning solid fuel appliances� Due to the dangers of creosote buildup and sparks entering the duct, these models

should be vented separately from all other kitchen equipment or in such a manner acceptable to the authority having jurisdiction�

The Wood Stone customer support staff is available to answer any questions concerning installation and venting of the oven; call

your local distributor for assistance and technical support�

Solid fuel exhaust contains creosote and other substances that accumulate in ducting, creating a risk of fire� The rate of

accumulation will vary with respect to flue gas temperature, wood type and moisture content� Frequent, regularly scheduled,

thorough flue cleaning is the best way to minimize the risk of flue fires� Wood Stone recommends cleaning and inspection at

least monthly on any ventilation system serving solid fuel equipment.

CREOSOTE - AND THE NEED FOR ITS REMOVAL

When wood is burned slowly, it produces tar and other organic vapors, which combine with expelled moisture to form creosote�

The creosote vapors condense in the relatively cool oven flue of a slow-burning fire� As a result, creosote residue accumulates

in the duct� When ignited, this creosote makes an extremely hot fire� The duct serving this oven should be inspected at least

twice a month during the first two months of operation, to establish rate of creosote buildup and necessary cleaning schedule� If

creosote or soot has accumulated, it should be removed to reduce the risk of a flue fire� Wood Stone recommends cleaning

and inspection at least monthly on any ventilation system serving solid fuel equipment.

WOOD STONE RECOMMENDS THAT THE OPERATOR REFER TO THE EXHAUST HOOD MANUFACTURERS FOR

INSPECTION, MAINTENANCE AND CLEANING.