User manual

Hoof trimmingcrush:SA0035

Version: 24-09-14

Page 5 of 29

Table of Contents

INTRODUCTION...............................................................................................................................................3

WARRANTY.....................................................................................................................................................4

TABLE OF CONTENTS....................................................................................................................................5

EC CONFORMITY DECLARATION (COPY)......................................................................................................6

OVERVIEW OF SYMBOLS...............................................................................................................................7

PICTOGRAMS..................................................................................................................................................8

1. TECHNICAL INFORMATION.....................................................................................................................9

2. DESCRIPTION OF THE INSTALLATION.................................................................................................10

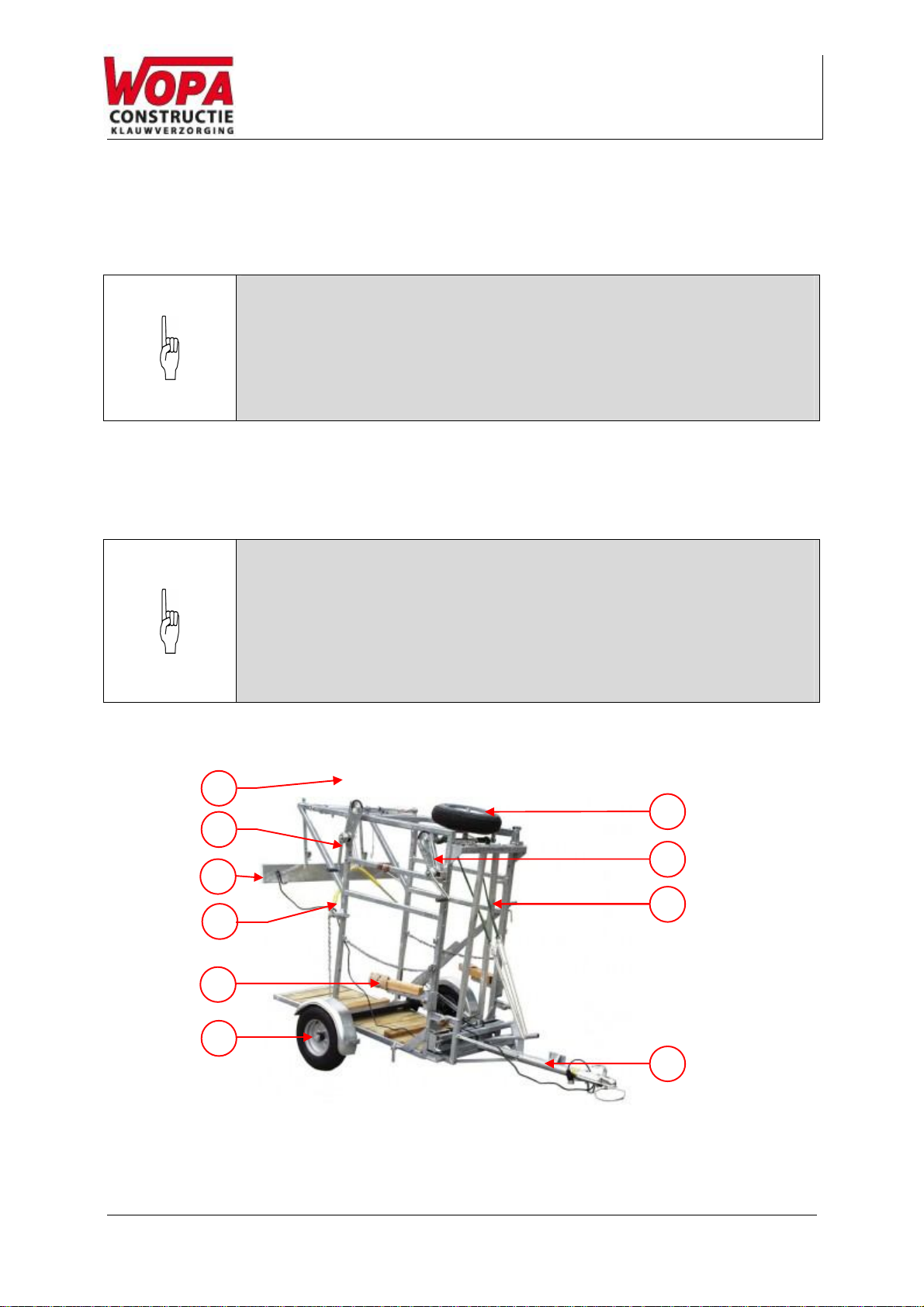

2.1. DESCRIPTION OF THE MAIN COMPONENTS SA0035 ................................................................10

2.2. ELECTRICAL INSTALLATION ..................................................................................................12

3. SAFETY..................................................................................................................................................14

3.1. GENERAL...........................................................................................................................14

3.2. DURING NORMAL USE..........................................................................................................15

3.3. OPERATING PERSONNEL......................................................................................................15

4. INSTALLATION......................................................................................................................................16

4.1. LOCATION..........................................................................................................................16

4.2. CONNECT THE MACHINE. .....................................................................................................18

4.3. PREPARING FOR TRANSPORTATION.......................................................................................18

5. OPERATION...........................................................................................................................................19

5.1. STARTING UP .....................................................................................................................19

5.2. EMERGENCY STOP..............................................................................................................19

5.3. PRODUCTION .....................................................................................................................20

5.4. HOOK UP THE FRONT LEG....................................................................................................21

6. MAINTENANCE......................................................................................................................................22

6.1. MAINTENANCE DIAGRAM......................................................................................................23

6.2. CLEAN THE MACHINE...........................................................................................................24

6.3. LUBRICATION OF REAR GATE................................................................................................24

6.4. CHECK PLAY IN THE WHEELS................................................................................................25

6.5. PARTS...............................................................................................................................26

7. DISPOSAL AS WASTE...........................................................................................................................27

8. APPENDIX..............................................................................................................................................28

8.1. LOGBOOK..........................................................................................................................28

LIJST MET AFBEELDINGEN

FIGURE 1: OVERVIEW SA0035.............................................................................................................10

FIGURE 2: OVERVIEW OF THE ELECTRICAL INSTALLATION (THE TYPE OF HOOF TRIMMING CRUSH IN THE PHOTO

MAY DIFFER FROM YOUR INSTALLATION)..........................................................................................12

FIGURE 3: DETAILS OF CONVERSION FROM TRANSPORT SET-UP TO WORKING SET-UP..................................16

FIGURE 4: DETAIL OF HOOKING UP FRONT LEG ........................................................................................21

FIGURE 5: LUBRICATION OF REAR GATE..................................................................................................24