LWCC-M

World Precision Instruments i

CONTENTS

ABOUT THIS MANUAL ................................................................................................................... 1

INTRODUCTION .............................................................................................................................. 1

General Warnings and Cautions ........................................................................................... 2

INSTRUMENT DESCRIPTION ........................................................................................................ 2

Parts List...................................................................................................................................... 2

Unpacking................................................................................................................................... 2

Hardware Description.............................................................................................................. 3

Required But Not Provided (see Accessories).............................................................. 3

Assembly ............................................................................................................................... 3

OPERATING INSTRUCTIONS......................................................................................................... 4

Transmission Verication........................................................................................................ 4

Noise Determination................................................................................................................ 4

Refractive Index......................................................................................................................... 4

Measuring in a Continuous Flow........................................................................................... 5

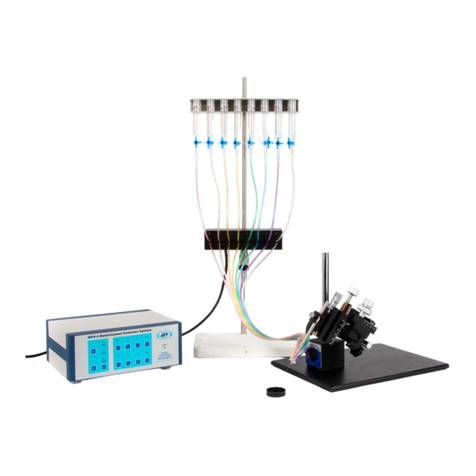

Measuring Discrete Samples with WPI’s Injection System.............................................. 5

INSTRUMENT MAINTENANCE...................................................................................................... 6

Standard Cleaning .................................................................................................................... 6

Advanced Cleaning .................................................................................................................. 6

Storage ........................................................................................................................................ 7

ACCESSORIES................................................................................................................................... 7

TROUBLESHOOTING ..................................................................................................................... 8

Typical Contamination Eects................................................................................................ 8

Additional Information on Contamination.......................................................................... 9

SPECIFICATIONS............................................................................................................................10

Related Patents .......................................................................................................................10

INDEX...............................................................................................................................................11

WARRANTY .....................................................................................................................................12

Claims and Returns ................................................................................................................12

Copyright © 2017 by World Precision Instruments, LLC. All rights reserved. No part of this publication

may be reproduced or translated into any language, in any form, without prior written permission of

World Precision Instruments, Inc.