Micromanipulator Care Guide

World Precision Instruments iii

Copyright © 2013 by World Precision Instruments, Inc. All rights reserved. No part of this publication

may be reproduced or translated into any language, in any form, without prior written permission of

World Precision Instruments, Inc.

CONTENTS

ABOUT THIS MANUAL........................................................................................................................ 1

INTRODUCTION.................................................................................................................................... 1

Notes and Warnings....................................................................................................................... 1

INSTALLING THE TILT BASE............................................................................................................... 2

ADJUSTING THE ANTI-DRIFT TENSION ON MICROMANIPULATORS.................................... 2

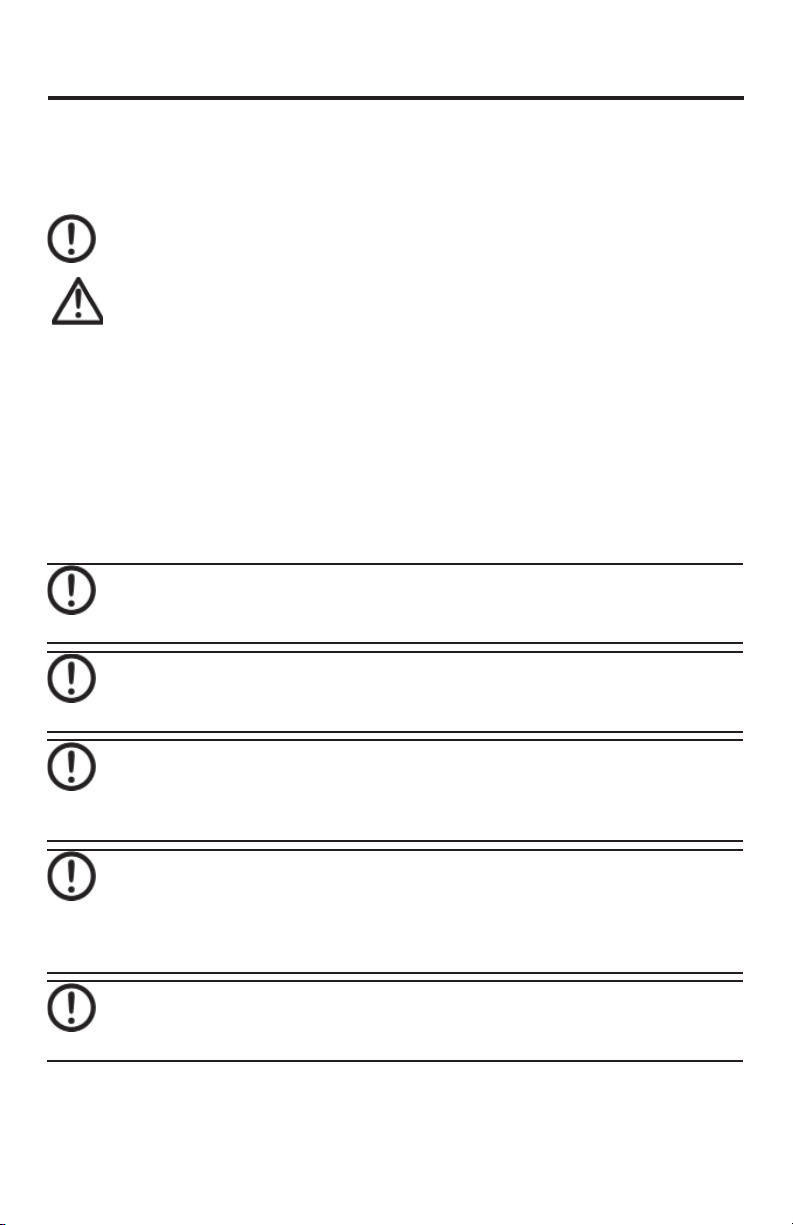

Adjusting the X Coarse Axis Drift ............................................................................................... 3

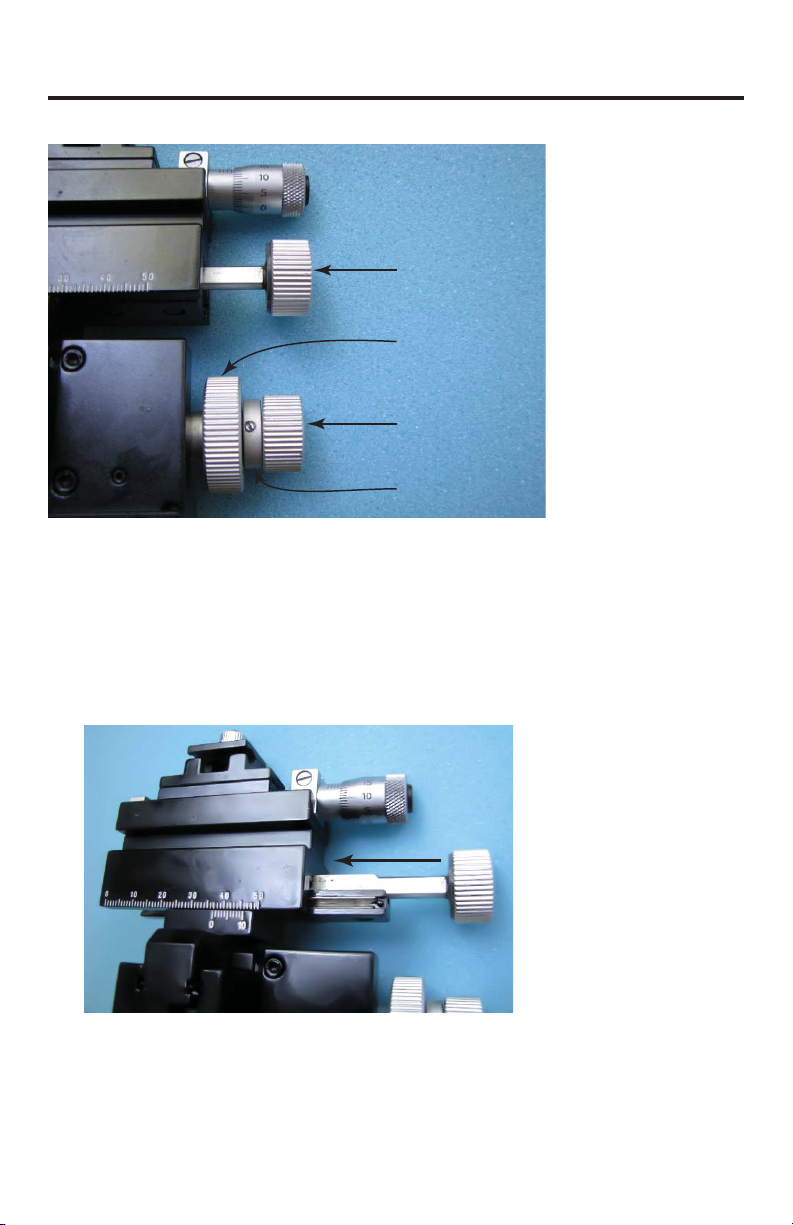

Adjusting the Y-Axis Drift .............................................................................................................. 6

Adjusting the Z Axis Drift.............................................................................................................. 6

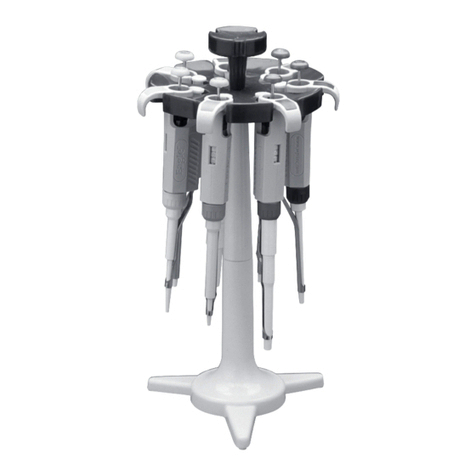

ACCESSORIES........................................................................................................................................ 8

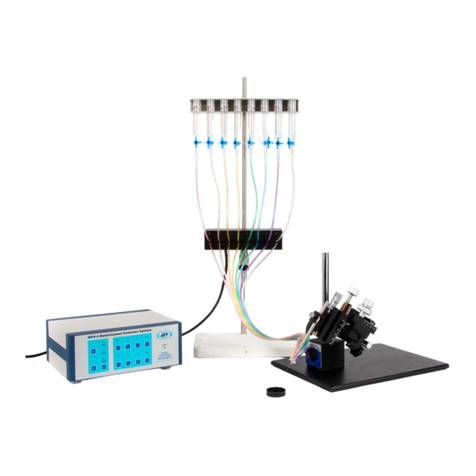

Manipulators.................................................................................................................................... 8

Optional Accessories...................................................................................................................... 8

SPECIFICATIONS................................................................................................................................... 8

KITE .................................................................................................................................................... 8

M3301............................................................................................................................................... 9

MD4R................................................................................................................................................. 9

MMJ.................................................................................................................................................... 9

DC3001............................................................................................................................................. 9

0.2mm/s............................................................................................................................................ 9

0.2mm/s............................................................................................................................................ 9

0.2mm/s............................................................................................................................................ 9

WARRANTY..........................................................................................................................................11

Claims and Returns ......................................................................................................................11

Repairs.............................................................................................................................................11