Page 2 of 42 pages

Content

SUBJECT

Page

INDEX 3

1. BASICS 6

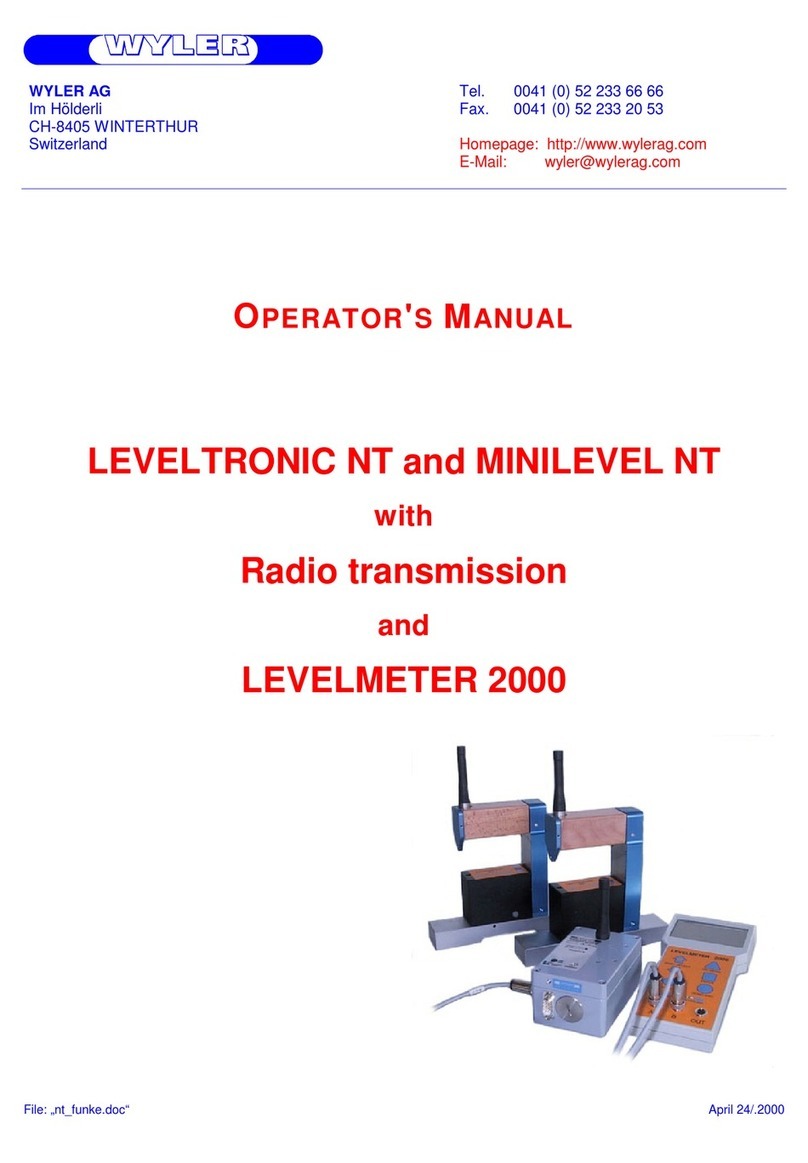

1.1. Instrument's overview 6

1.2. Measuring instruments / External display instruments 7

1.3. Measuring procedure / general use 8

1.3.1

Basic set-up of the inclination measuring instruments / plus - minus rule 8

1.3.2 Absolute measurement / Relative measurement / Differential measurement 9

1.3.3

General remarks about "ANGLES" 10

1.3.4

Height related to the step length 11

1.4. Zero setting by reversal measurement (Absolute ZERO) 12

1.5. Applications 12

1.5.1 Measuring absolute 12

1.5.2 Measuring relative 12

1.5.3 Differential respectively reference measurement using an engineer set 13

1.5.4 Angular measurements 15

1.5.5 Lines and flatness measurement (manual procedure) 16

1.6. WYLER software LEVELSOFT 17

2. DETAILED INFORMATION to the various instruments 19

2.1. MINILEVEL / LEVELTRONIC „classic“ 19

2.1.1 MINILEVEL “classic” A10 / LEVELMETER C25/DC (red cover) 19

2.1.2 LEVELMETER C25 / DC 20

2.1.3 LEVELTRONIC “classic” A40 / LEVELMETER 25 (blue cover) 22

2.1.4 LEVELMETER 25 22

2.2. MINILEVEL / LEVELTRONIC „NT“ 24

2.2.1 MINILEVEL “NT” 11 / LEVELMETER C25 (red cover) or

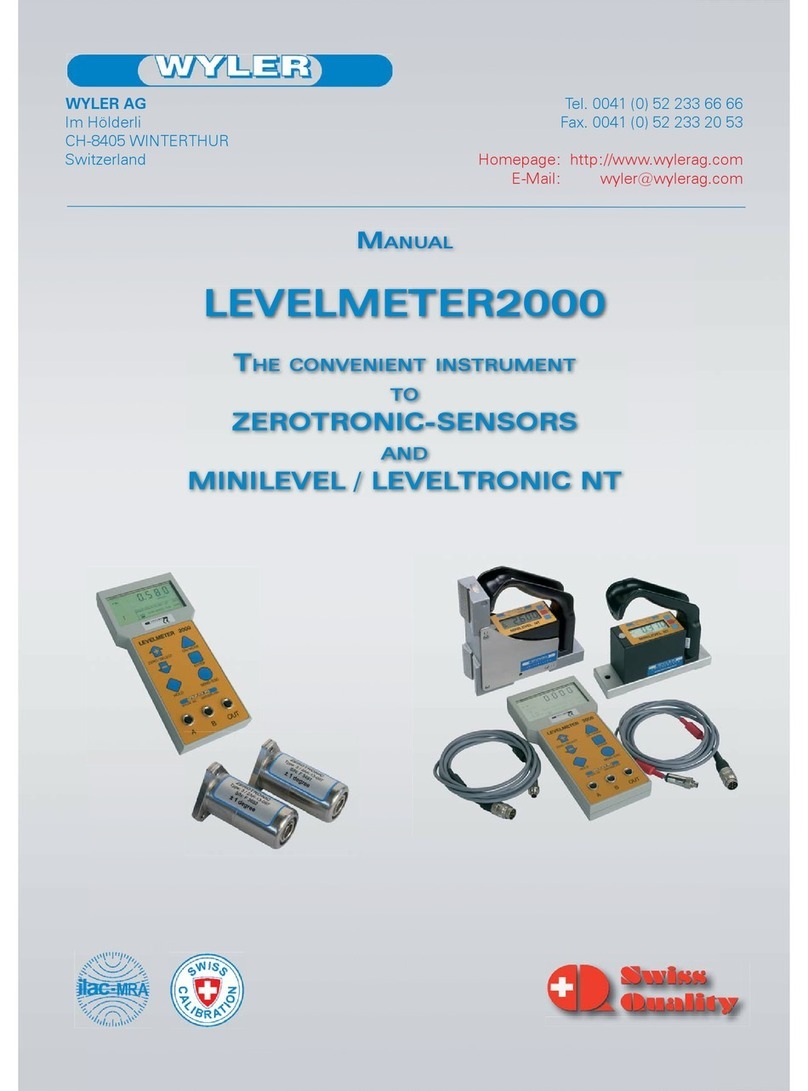

LEVELMETER 2000

24

2.2.2 LEVELMETER C25/DC 25

2.2.3 LEVELMETER 2000 26

2.2.4 LEVELTRONIC “NT” 41 with LEVELMETER C25/DC (red cover) or

LEVELMETER 2000

31

2.2.5 LEVELMETER C25/DC 32

2.2.6 LEVELMETER 2000 33

3. TECHNICAL DATA 38

3.1. LEVELTRONIC “classic” / A40 38

3.2. LEVELTRONIC “NT” / 41 38

3.3. MINILEVEL “classic” / A10 38

3.4. MINILEVEL “NT” / 11 39

4. MAINTENANCE 39

4.1. Easily cured difficulties 39

5. ACCESSORIES / SPARE PARTS 41

6. STORING Instruments / Care and handling of the batteries 41/42

7. REPAIR OF MEASURING INSTRUMENTS 42

Änderungen / Modifications:

Datum / Date Geändert durch

Modified by

Beschreibung der Änderung

Description of modifications

5.9.2000 HEH Fig. 9 / Seite 11 neu

27.3.2001 HEH Data collection using ENTER key

10.1.2003 HEH/MO Index included, Levelsoft PRO, deactivation autom. shut off

2.4.2003 HEH New:Express Repair Service