Seite 2 von 53 Seiten

Content

Subject Page

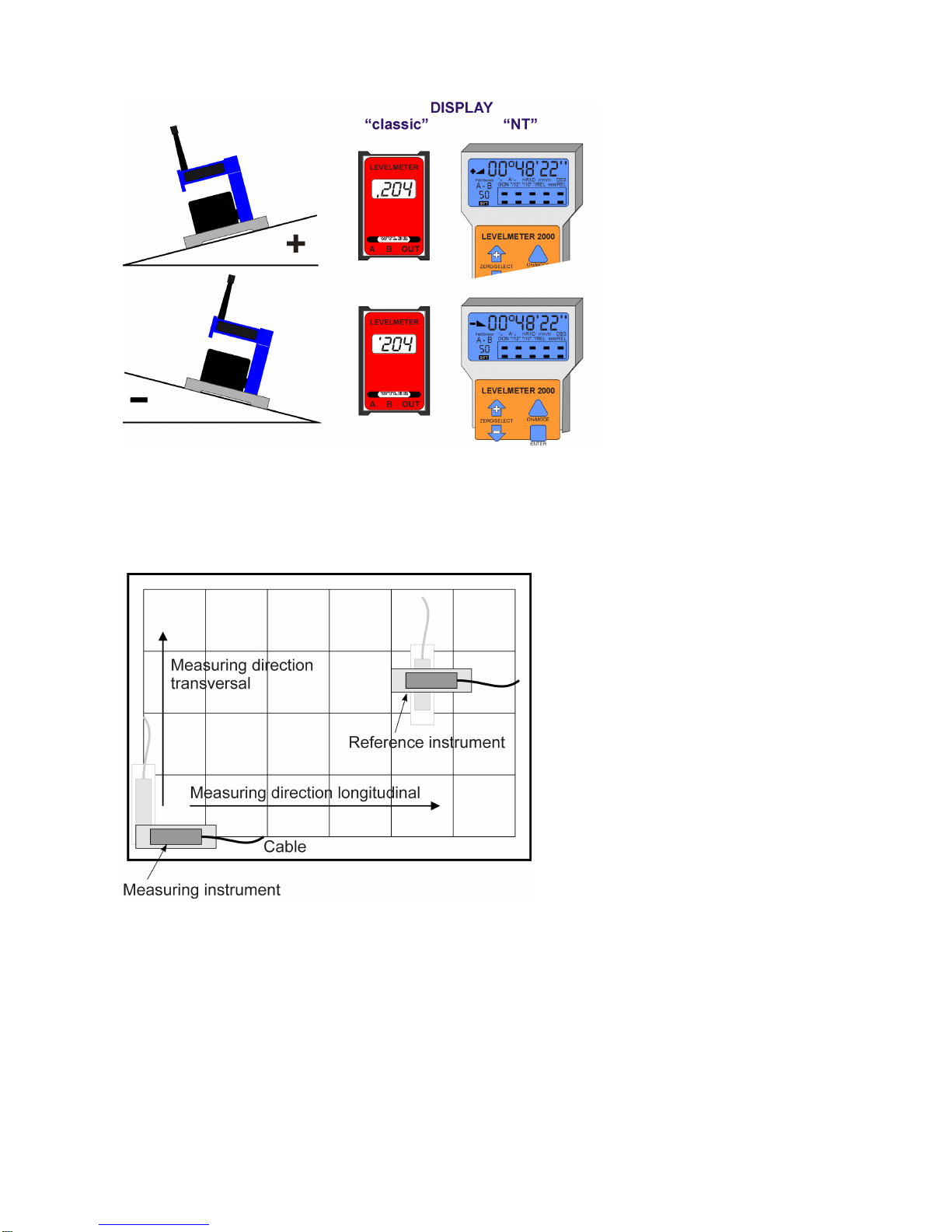

1. BASICS 3

1.1. Instrument's overview 3

1.2. Measuring instruments / External display instruments 4

1.3. Measuring procedure / general use 6

1.4. Zero setting by reversal measurement (Absolute ZERO) 11

1.5. Applications 11

1.6. WYLER software LEVEL SOFT 16

2. DETAILED INFORMATION to the various instruments 18

2.1. MINILEVEL / LEVELTRONIC „classic“ 18

2.2. MINILEVEL / LEVELTRONIC „NT“ 32

3. TECHNICAL DATA 45

3.1. LEVELTRONIC NT 45

3.2. MINILEVEL NT 45

3.3. RADIO MODULE 46

4. UPGRADE OF MINILEVEL NT AND LEVELTRONIC NT TO RADIO TRANSMISSION UNITS 47

5. MAINTENANCE / easy to cure malfunctions 49

6. ACCESSORIES / SPARE PARTS 51

7. STORING 51

8. DECLARATION OF CONFORMITY 52

Änderungen / Modifications:

Datum / Date Geändert durch

Modified by Beschreibung der Änderung

Description of modifications

The following manuals are ready for download on the internet homepage http://www.wylerag.com:

• DYNAM, the software for measuring and monitoring for use with ZEROTRONIC-

sensors

• LEVELSOFT WIN99, the software for inclination and flatness measurement with

WYLER inclination measuring instruments

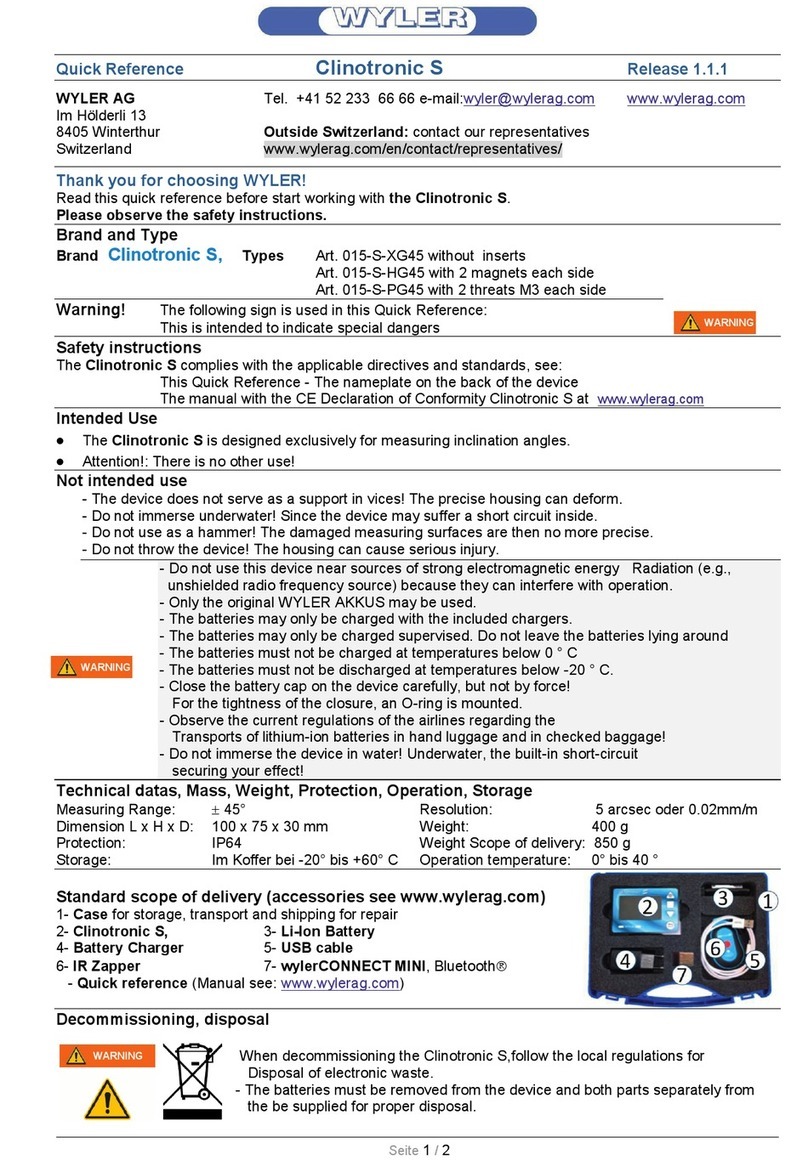

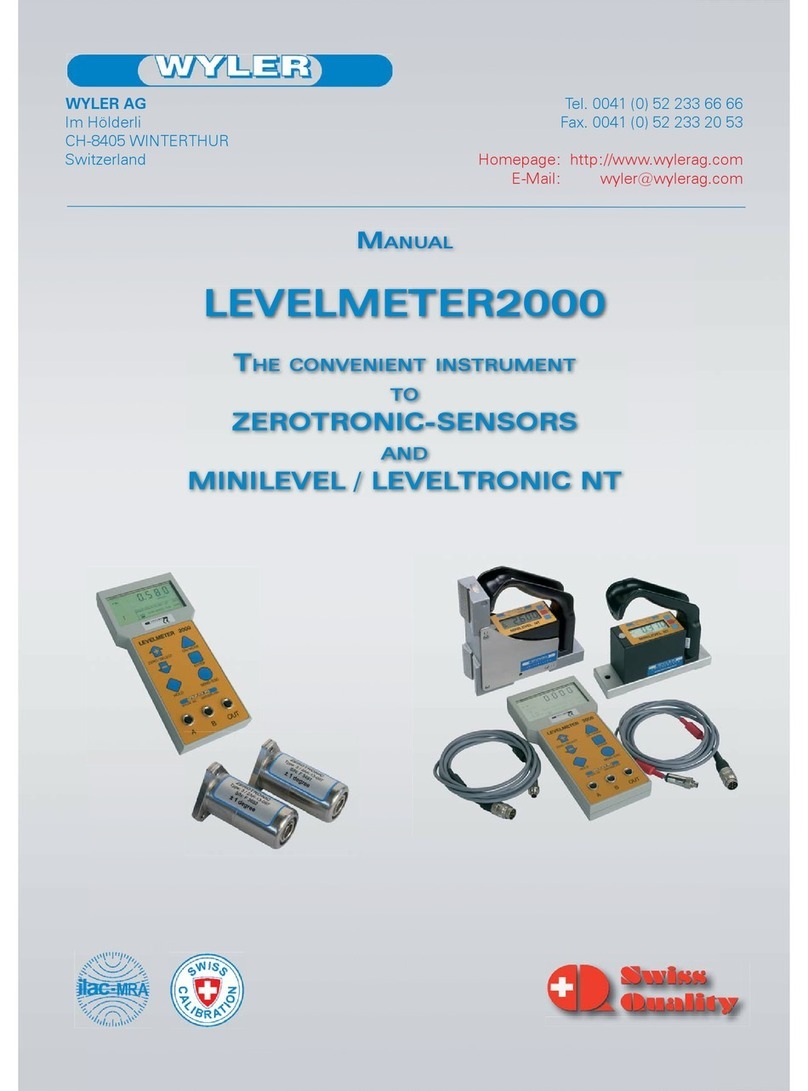

• LEVELMETER 2000

• LEVELMETER „light“

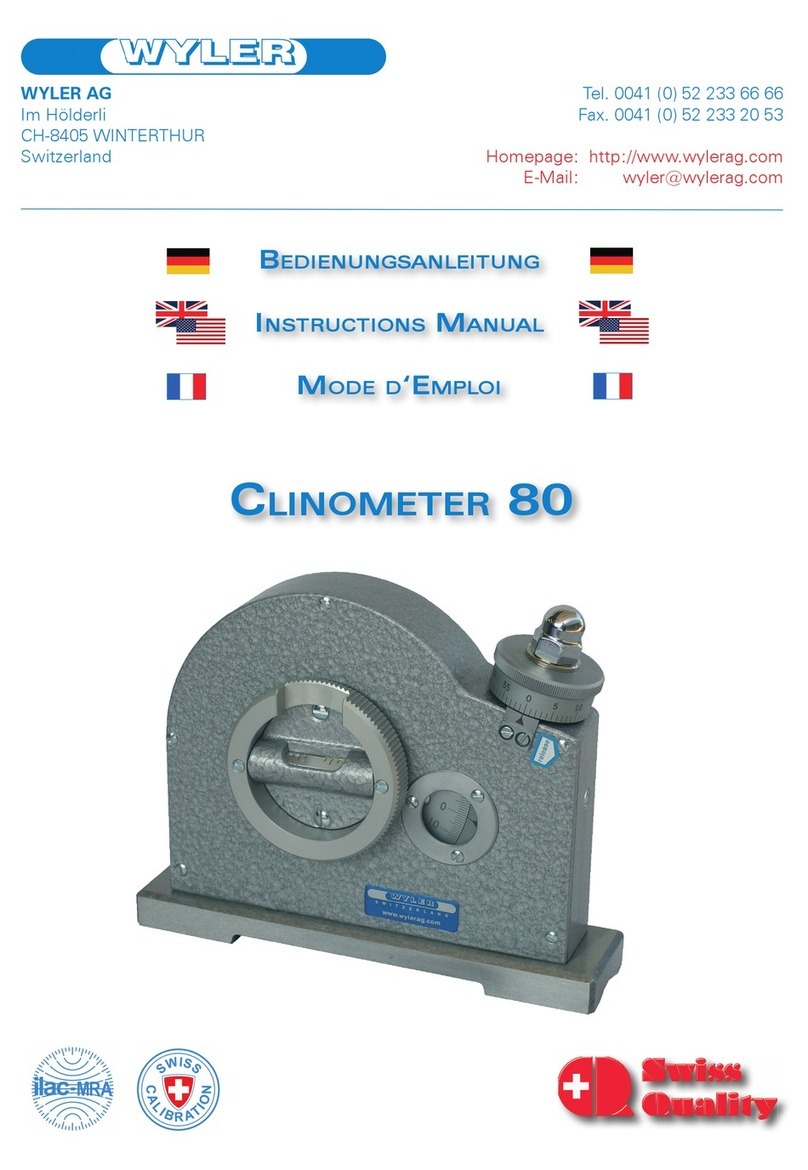

• +CLINO PLUS+, the handy inclination measuring instrument

• CLINO 2000, the instrument with a number of features

• MINILEVEL / LEVELTRONIC „classic“ and „NT“

• Remote Display, the simple display unit

• COMPENDIUM, the informative brochure for our agents with an overview on our

products, technologies and applications

• Interface description RS485

These manuals can also be received against a nominal fee on a CD „ALL-IN-ONE“ if ordered at WYLER AG.

On this CD the manuals are available in different languages