Page 9 of 31 Pages

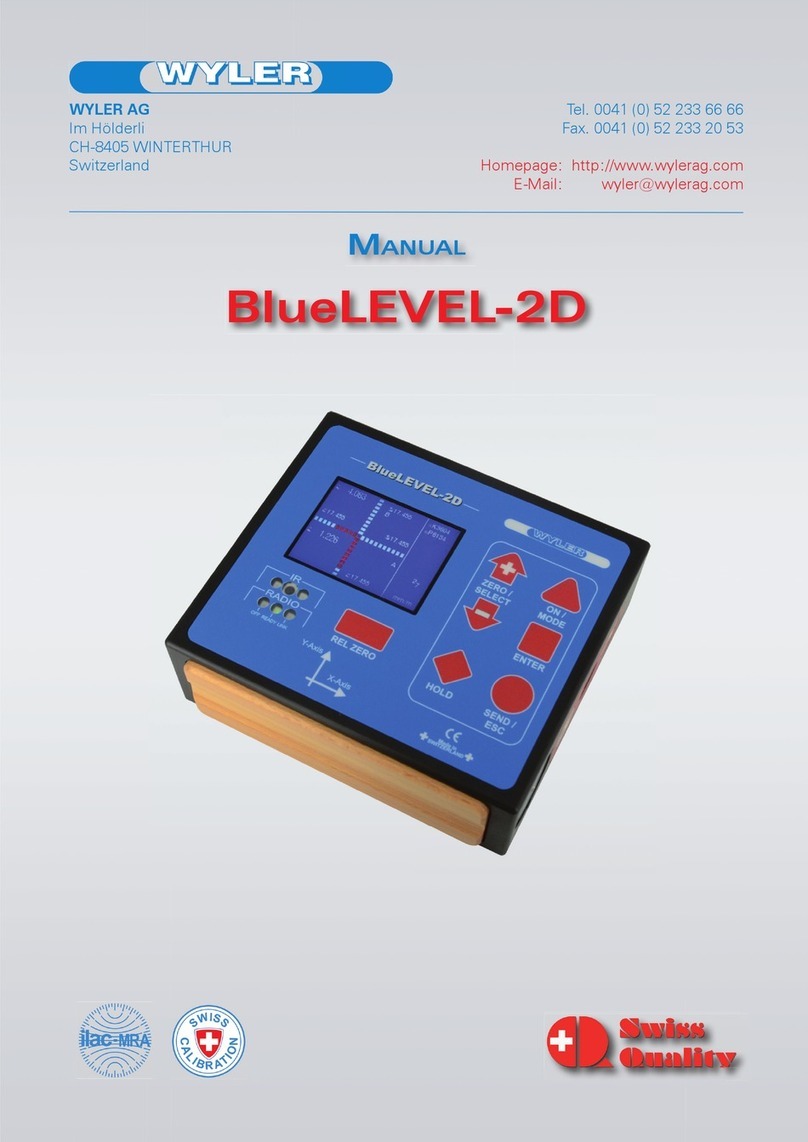

2.2. Panel/Functions

2.2.1. Description of the key functions

ON/MODE - Key

Function - 1 - Pressing the ON/MODE key starts the LEVELMETER 2000. When keeping the key

pressed all the LCD elements are lighted. After releasing the key the instrument

switches to the measuring mode if a sensor is connected and the calibration data of this

sensor has been collected. After a short period of time the actual angle will be displayed

in the last used measuring unit. In case of trouble an error message will be displayed.

(See point 5)

Disabling the automatic shut-off of the LEVELMETER 2000

When pressing the ON/MODE key for more than 3 seconds the display

starts flashing and the automatic shut off is disabled. In the standard mode the

instrument shut off after about 10 minutes.

Exeption: In case the LEVELMETER 2000 is powered by a connection to a

mains adapter, the instrument is never shutting off automatically.

Function - 2 - The ON/MODE is also used for moving the selection pointer on the lower display

area. By pressing this key the selection pointer moves from one position to the next.

Function - 3 - For shutting off the LEVELMETER 2000; the ON/MODE key needs to be pressed for

a few seconds until the displayed figures disappear. If the key is pressed min.

15 seconds a date and a 4 digit number appears. This is the status of the software

release of the Levelmeter.

Function - 4 - Used for „ZERO-Setting“ of saved (memory) values in the functions „REL ZERO“ and

„ZERO“ To set the memory in these two functions to ZERO press the ON/MODE

key, the displayed values will become ZERO. This has to be confirmed by pressing

ENTER

ENTER – Key

The key ENTER is used to save an entered value or to accept a selected function.

When using the Software LEVELSOFT the key <ENTER> has the identical function

as the push button of the connecting cable (Dongle cable) or the push button of the

infrared sender unit for data collection.

SEND/ESC- Key

Function - 1 - The key SEND is used for the transmission of a measuring value through the RS232

port or to send the value to a printer or another connected system. Through the same

port the values may also be transmitted to a PC or Laptop for further treatment of the

data.

Function - 2 - Also used for canceling any „HOLD“ function and return to the measuring mode.

Function - 3 - Canceling any task not yet finished.