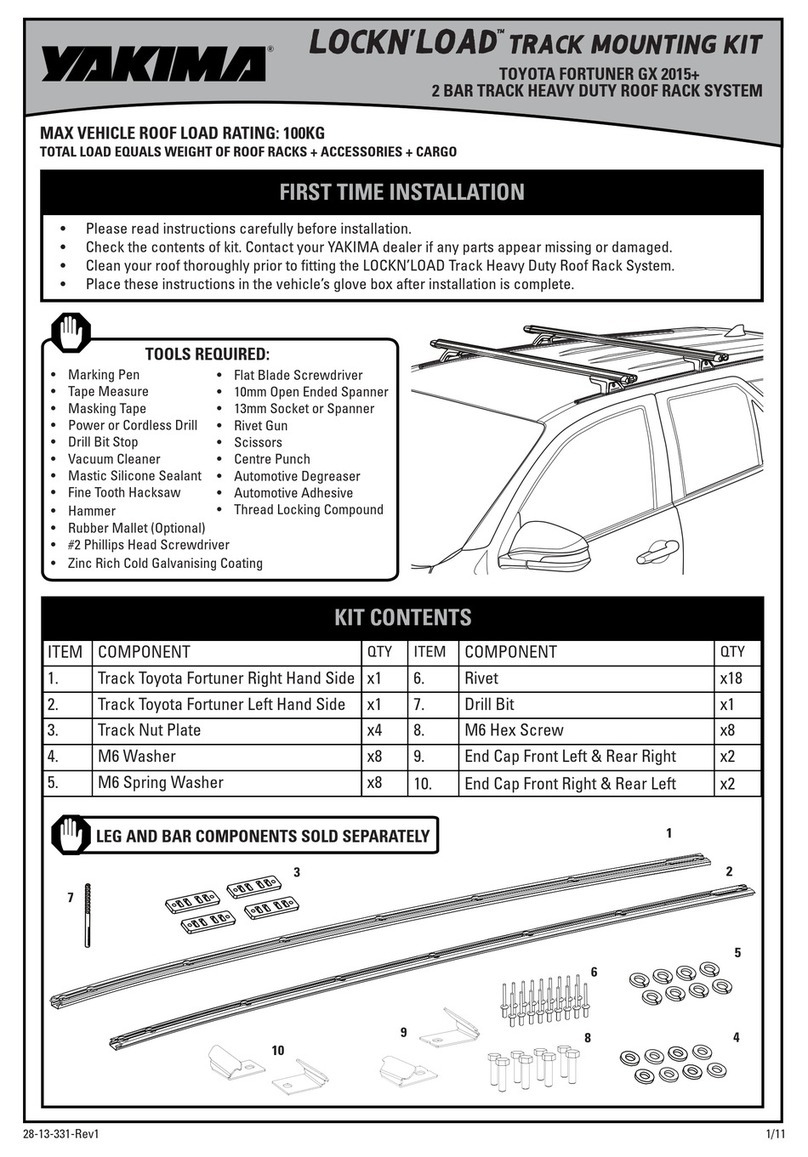

Yakima LockNLoad Track Mounting Kit User manual

Other Yakima Automobile Accessories manuals

Yakima

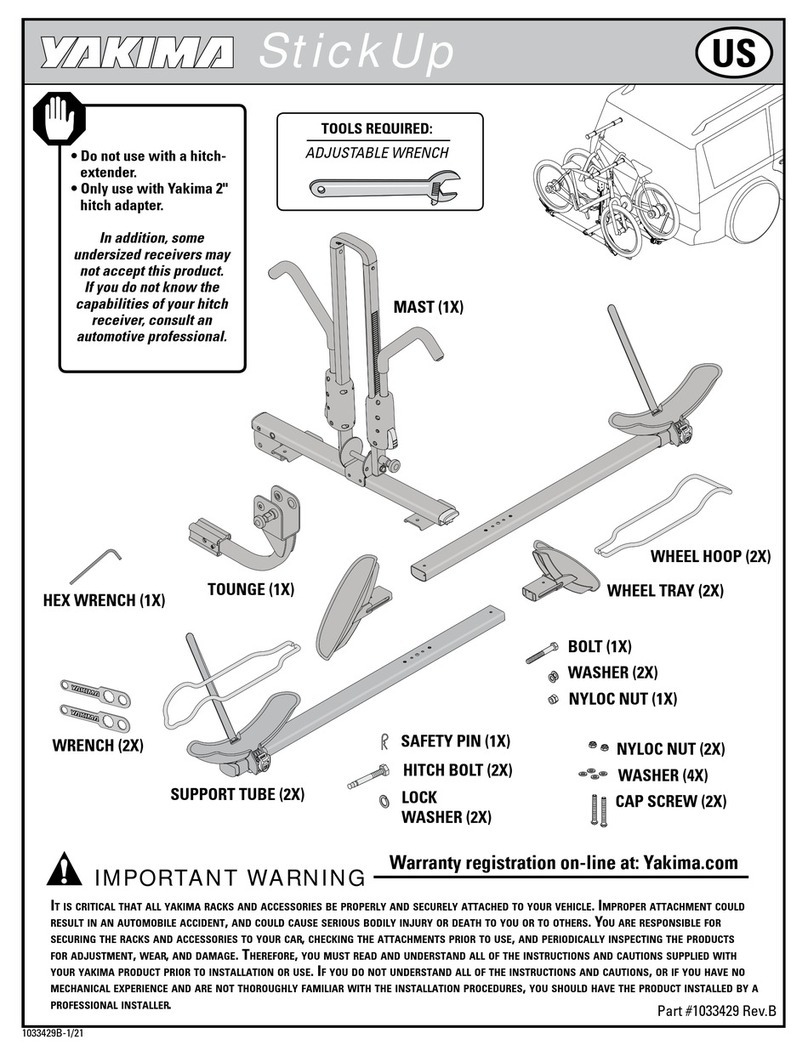

Yakima StickUp User manual

Yakima

Yakima MegaWarrior User manual

Yakima

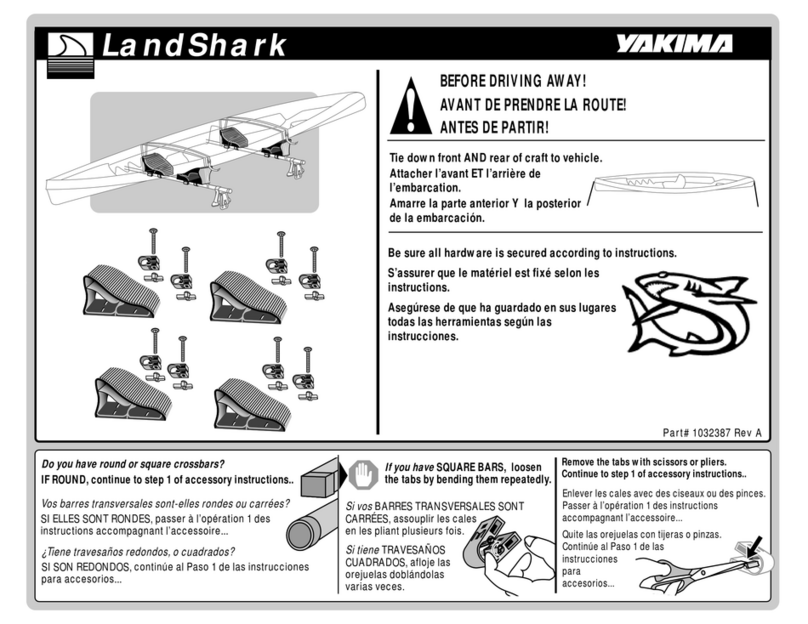

Yakima LANDSHARK User manual

Yakima

Yakima LockNLoad Mk2 User manual

Yakima

Yakima K1214 User manual

Yakima

Yakima Whispbar K720W User manual

Yakima

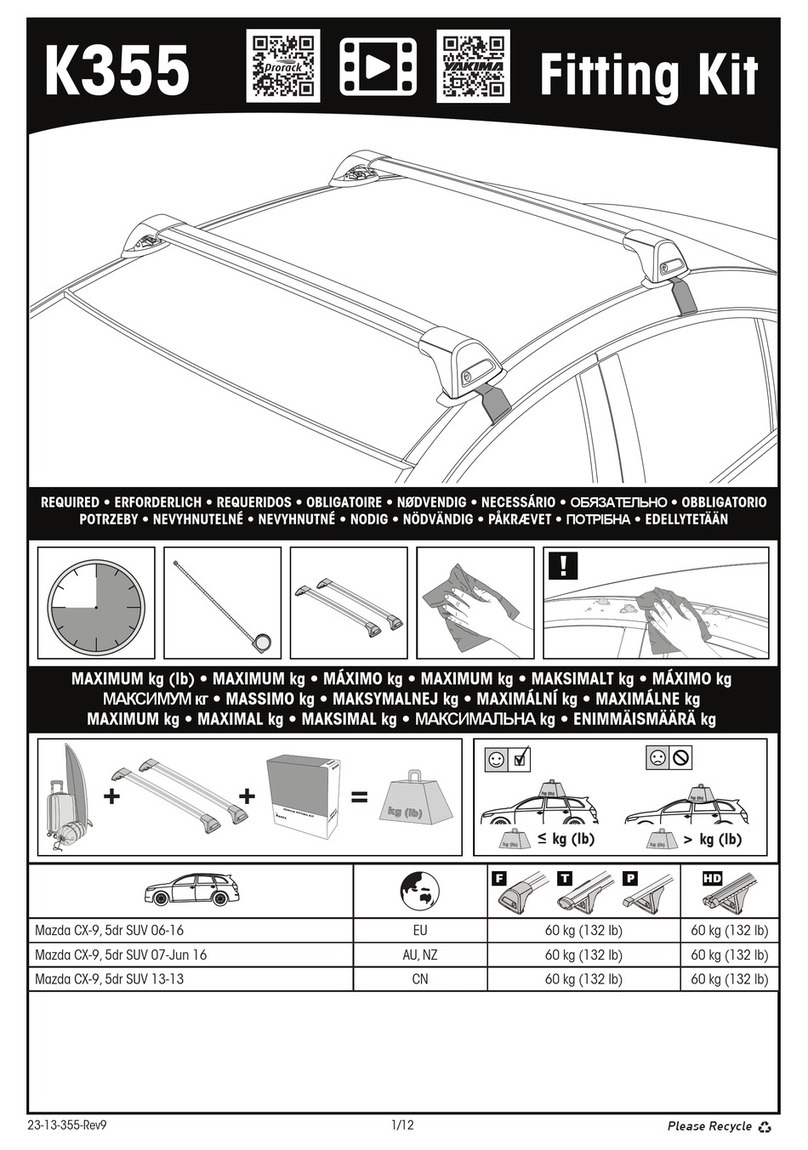

Yakima K355 User manual

Yakima

Yakima showdown User manual

Yakima

Yakima StickUp User manual

Yakima

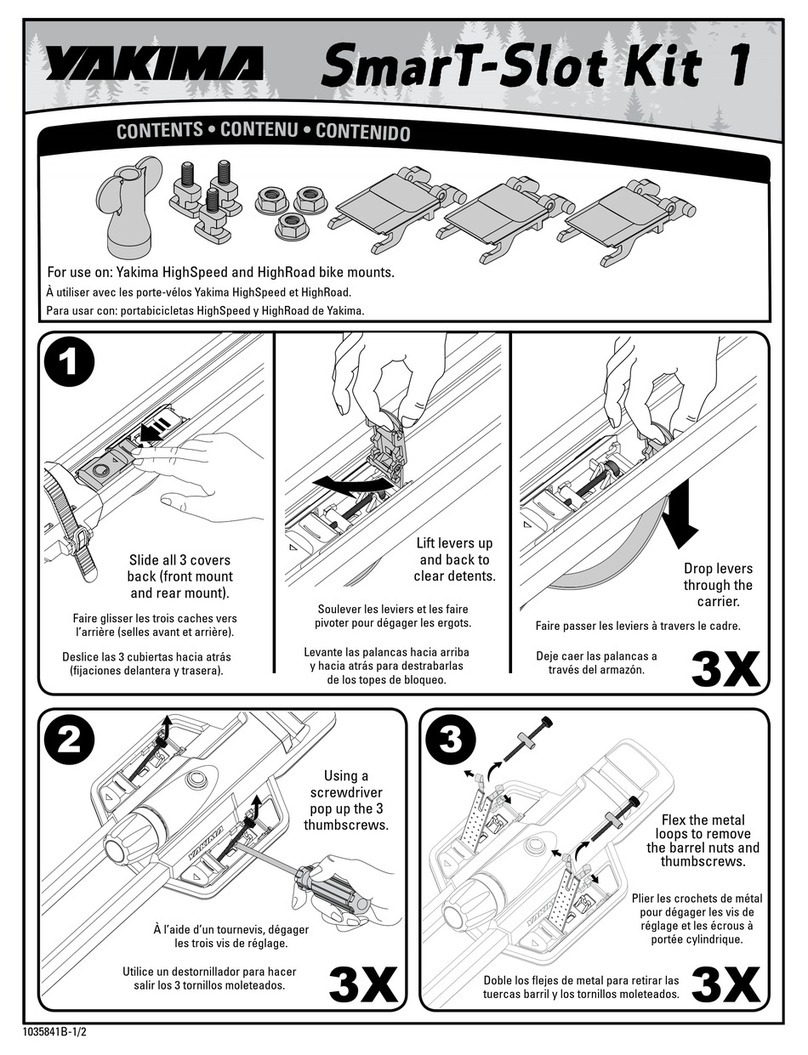

Yakima SmarT-Slot Kit 1 User manual

Yakima

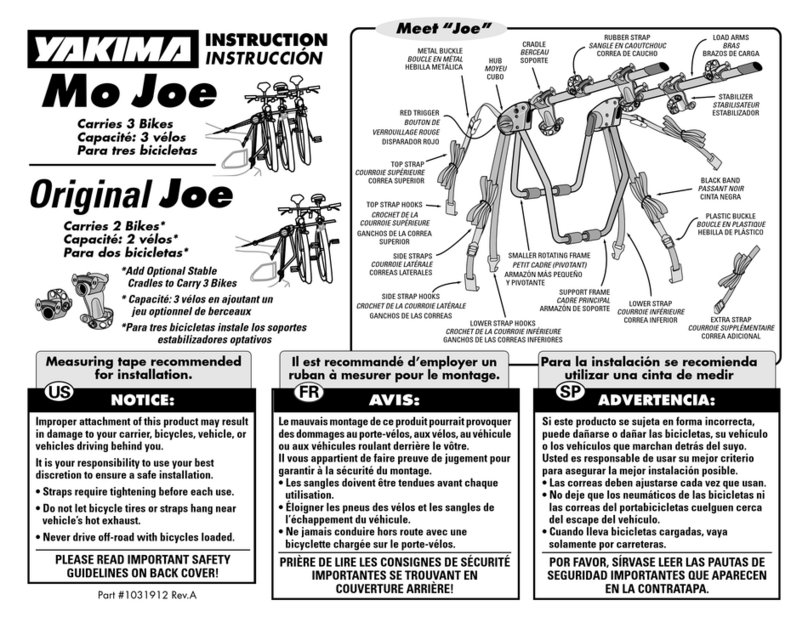

Yakima Mo Joe User manual

Yakima

Yakima K683 User manual

Yakima

Yakima Rail Bar User manual

Yakima

Yakima K158 User manual

Yakima

Yakima Whispbar K621W User manual

Yakima

Yakima LOCKN'LOAD User manual

Yakima

Yakima Hi-Lift 8007077 User manual

Yakima

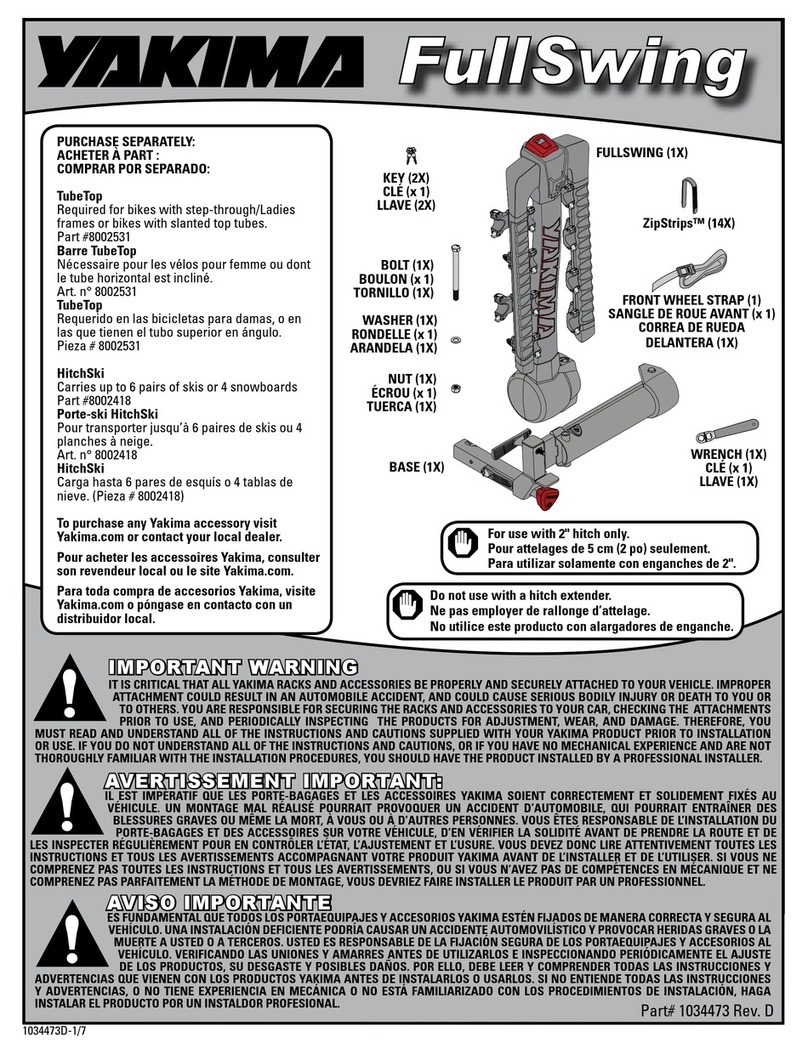

Yakima FullSwing User manual

Yakima

Yakima CopperHead User manual

Yakima

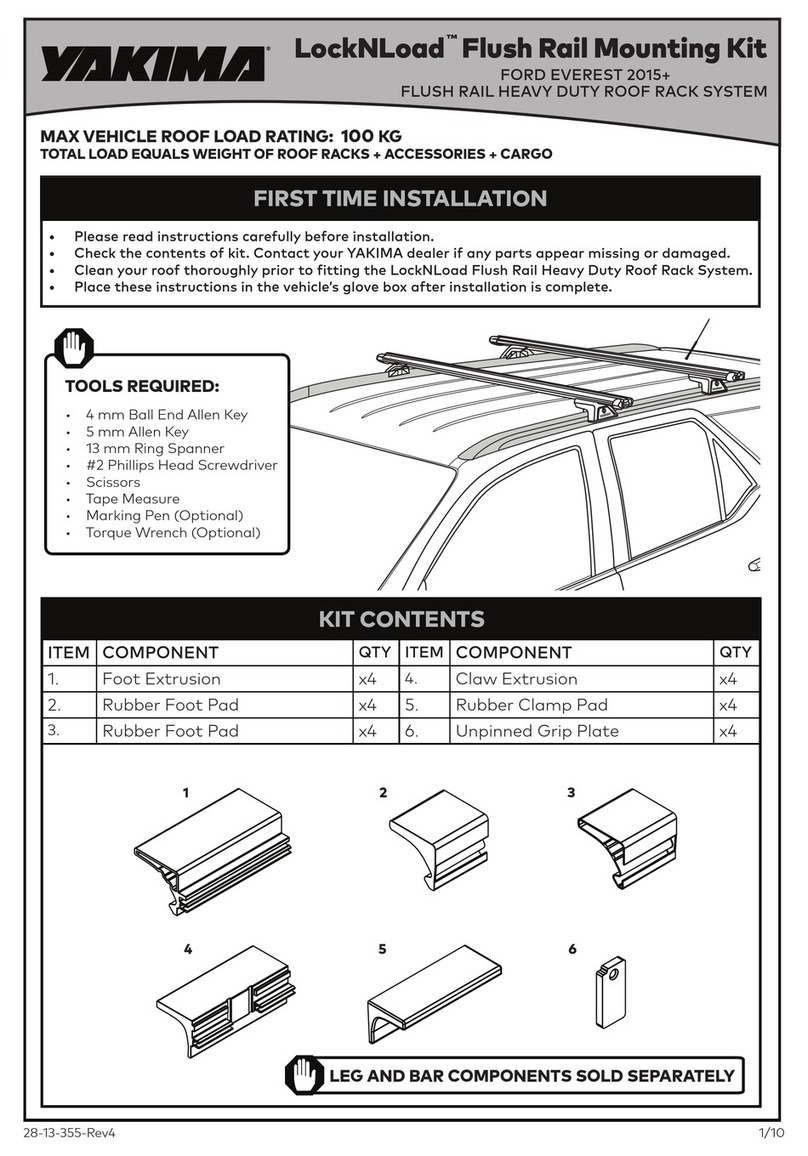

Yakima LockNLoad Flush Rail Mounting Kit User manual