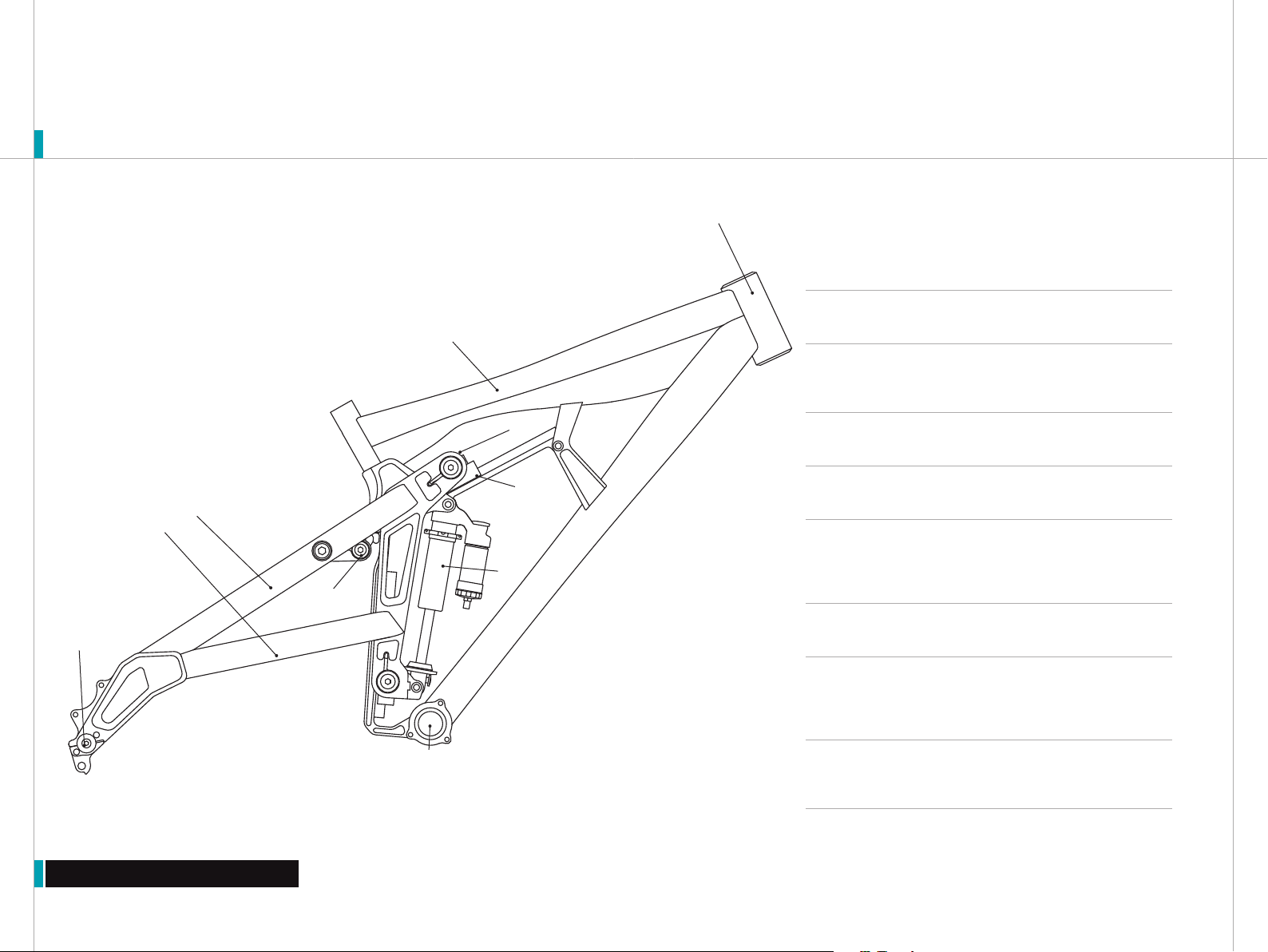

Shock Setup

SETUP SHOCK DHX 5.0

REBOUND The rebound adjustment has a 14-click range. Adjustments

that are too fast (counter-clockwise adjustment) will produce a

springy ride with excessive kick up of the rear end causing a bucking

sensation. Adjustments that are too slow (clockwise adjustment) will cause

packing of the rear wheel that is identified by a sluggish ride feeling.

Slower rebound - turn the adjuster clockwise

Faster rebound - turn the adjuster counter-clockwise

6

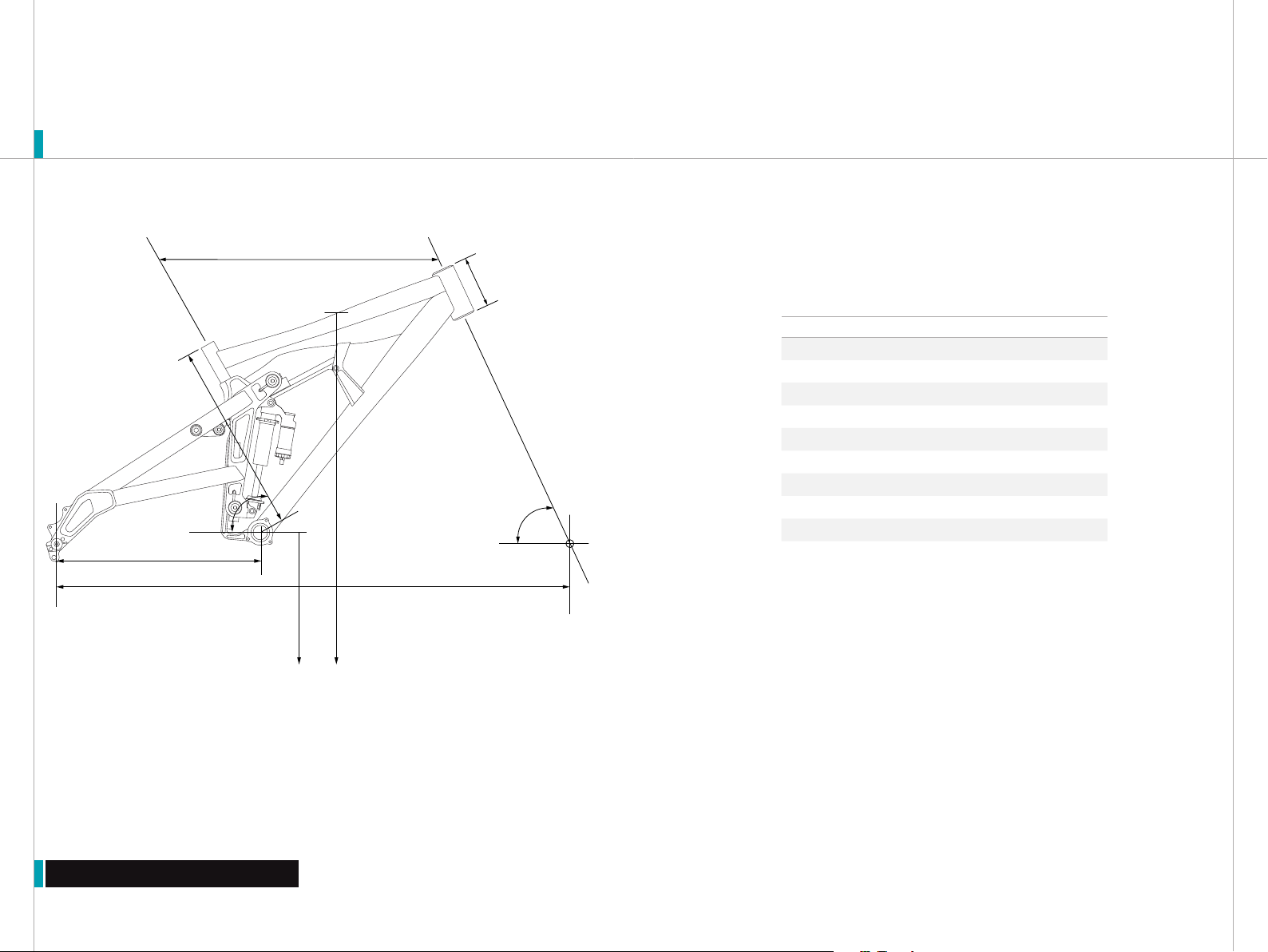

SAG SETUP Use 25-35% of the shocks stoke for downhill use. To

determine sag, first measure the distance between the centers of

each shock mounting bolt (eye-to-eye) and record this number. Make sure

you have the correct spring for your weight. See the spring rate chart.

>2006 303 DH eye-to-eye 9.5”

4

WHAT IS PRO-PEDAL? Pro-Pedal is compression tune that

gives the right amount of low speed compression to filter out

unwanted rider induced bob without sacrificing critical mid

and high speed damping. No flushing through your travel,

no wasted setup time, and no energy sucking suspension

movement, just super efficient pedaling performance ready

for hits of any size.

PRO-PEDAL The Pro-Pedal adjustment has a 15 click range of

adjustment. The Pro-Pedal damping affects the first half of stroke.

More Damping - clockwise rotation

Less Damping - counter-clockwise rotation

BOTTOM-OUT RESISTANCE The bottom-out adjuster has 3 full turns

of adjustment . This adjustment controls the bottoming resistance of

the shock, meaning it controls the compression on final part of the shocks

stroke. The adjuster can be turned by hand or with a 4mm allen key. The

allen key should be placed into one of the holes on the perimeter of the

adjuster.

More Resistance - clockwise rotation

Less Resistance - counter-clockwise rotation

Warning: When the volume adjuster has reached its counter-clockwise

stop limit, continued force on the adjuster may cause damage to the adjuster

mechanism.

BOOST VALVE The DHX 5.0 has an air pressure range of 75-200

psi, and it must be pressurized. The Boost Valve allows the Pro-

Pedal (beginning compression) and the Bottom-Out Resistance (ending

compression) to work seamlessly together. Because of this relationship the

Boost Valve pressure affects both the Bottom-Out Resistance and the Pro-

Pedal Adjustments (see adjustment relation).

Lower pressures (75-100 psi) - will decrease bottoming resistance and

Pro-Pedal at a given setting.

Higher pressures (110-200 psi) - will increase bottoming resistance and

Pro-Pedal at a given setting

SAG SETUP Next, sit on the bike and record the new (eye-to-eye)

measurement. Subtract the static eye-to-eye measurement from this

new measurement and you get your sag in inches. An easy way to calculate

sag is to multiply the shock travel by your desired sag percentage. See

quick setup guide on page 20.

5

Warning: Use of the shock with improper air pressure can cause a loss

of dampening and shock malfunction could occur. Do not attempt to turn the

adjuster with more than 125 psi in the chamber..

SETUP OVERVIEW The DHX 5.0 employs both speed sensitive rebound damping and position sensitive

compression damping. There are three external adjustments that affect the compression and one external

adjustment for the rebound. The three compression adjustments are the Bottom-Out Resistance, Boost Valve

and Pro-Pedal. The Pro-Pedal controls the anti-bob properties of the shock or the first part of the shocks

stroke, the Bottom-Out Resistance affects the end of the shocks stroke, and the Boost Valve damping links

these two adjustments together to create a seamless transition through the entire stroke. The Boost Valve

also de-couples the Pro-Pedal and Bottom-Out Resistance making these adjustments independent on each

other.

1

2

3