ASSEMBLY

Assembly

ASSEMBLY

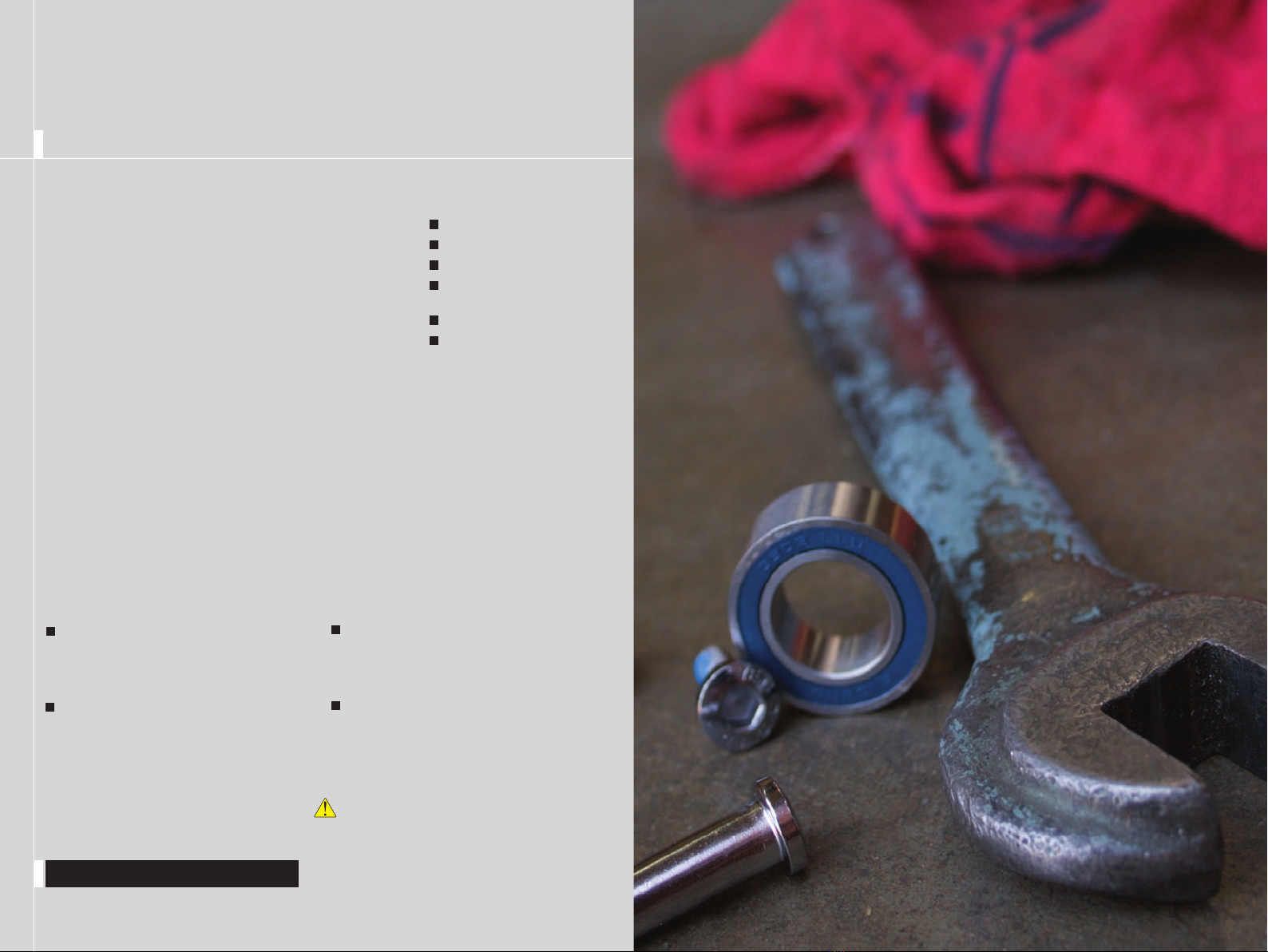

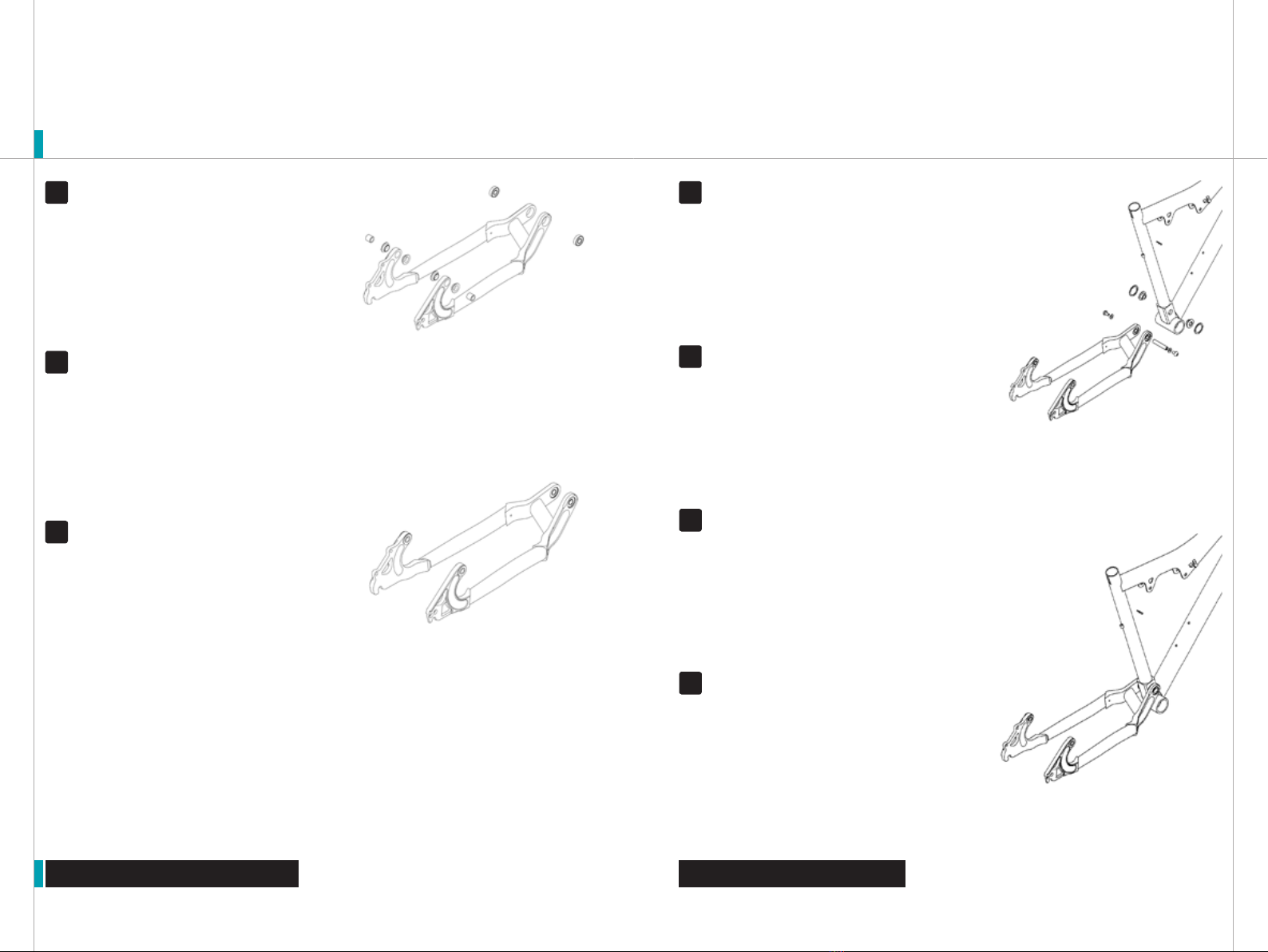

DOGBONE ASSEMBLY Press the two 1/4’’ long

Garlock bushings (9) into each side of the bottom end

of the dogbone (2). Ensure that the dogbone (2) bosses are

supported as the bushings (9) are pressed into place. The

Garlock bushings (9) should be pressed in level and flush

with the outside faces, as shown in Figure 2b.

DOGBONE ASSEMBLY Press the dogbone bushing

insert (8) into the Igus bushings (22) until there is equal

amount of insert sticking out each side of the Igus bushings

(22).

DOGBONE ASSEMBLY Place dogbone bushing spacers

(21) on each side of exposed dogbone bushing insert (8).

DOGBONE ASSEMBLY Install the two Igus bushings (22)

into the 15mm bore at the top part of the dogbone by

pressing the bushings level into the bore. The bushings (22)

should be pressed into the bore until the flanges are flush

with the bore face, as shown in Figure 2b.

Figure 2a: Dogbone (2) with bushings (22 &

9) and insert (8), exploded

Figure 2b: Dogbone (2) with

bushings (22 & 9) and insert (8),

assembled

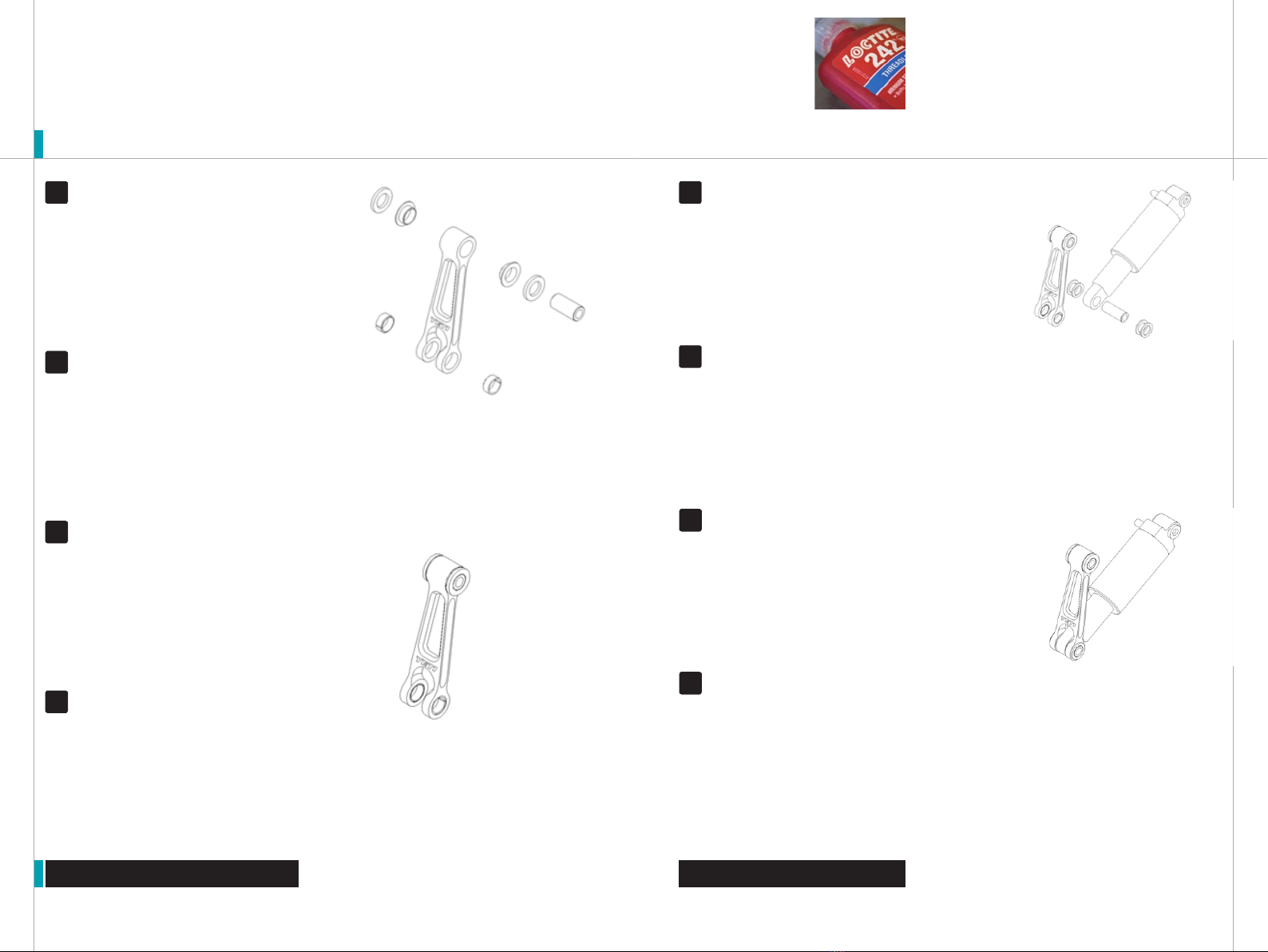

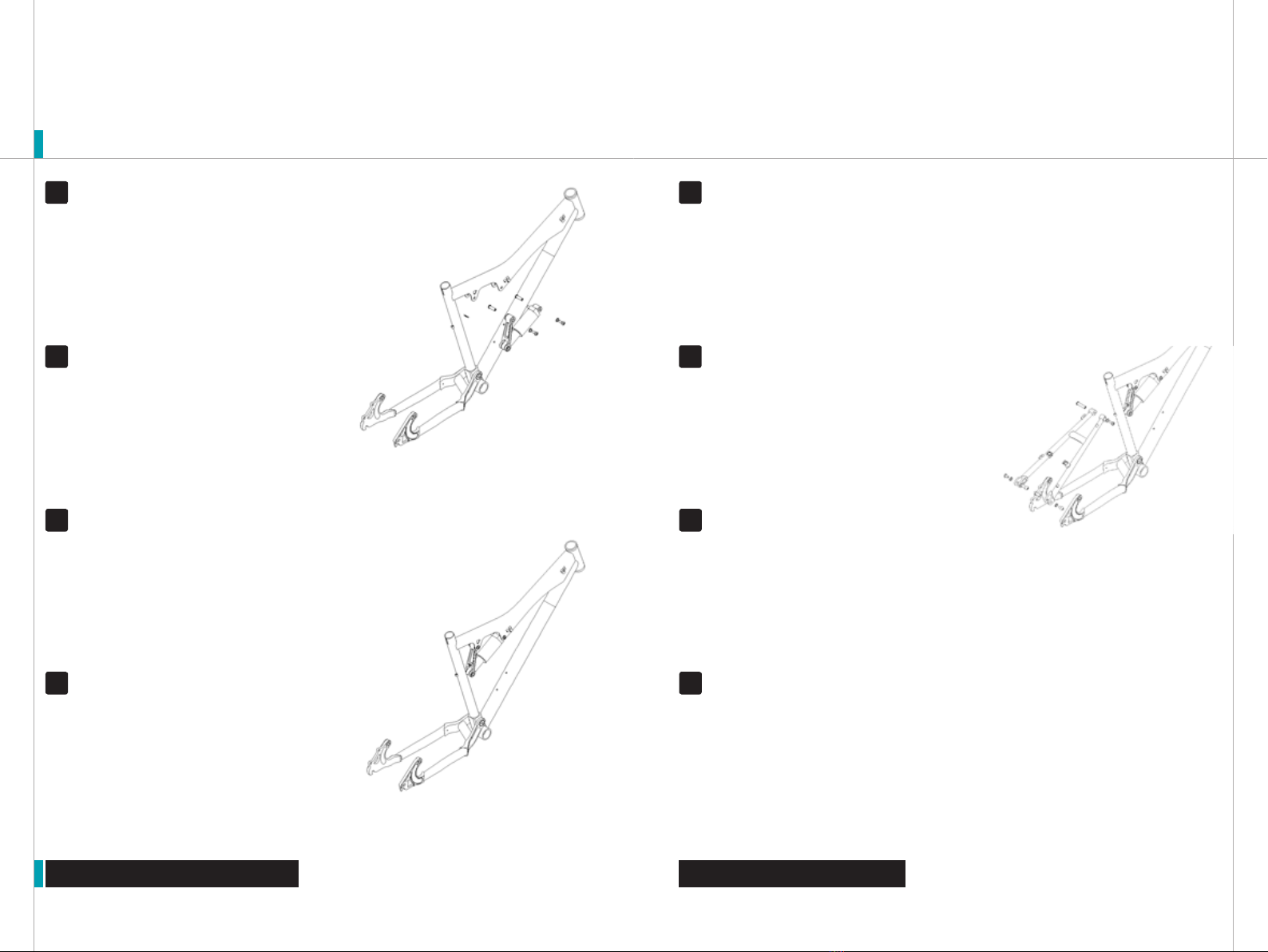

SHOCK ATTACHMENT While holding the black nylon

washer (11) to the dogbone (2), place the slider end of

the Fox shock (2) between the two bosses of the dogbone (2).

Line up the bushing bore in the Fox shock (3) with the Fox pin

(10) already pressed into the dogbone (2).

6

SHOCK ATTACHMENT Press the 1.3’’ Fox Pin (10)

into an installed Garlock bushing (9) at one end of the

dogbone. The pin should be all the way through one of the

bosses on one side with about 1/16th of an inch of the pin

(10) exposed on the inboard side. Place black nylon washer

(11) on the exposed inboard Fox pin (10) and hold in place by

hand.

5

SHOCK ATTACHMENT After lining up the Fox shock (3)

with the Fox pin (10), press the Fox pin (10) further into

the dogbone (2) and into the Fox shock (3) until the pin just

meet flush with the other side of the Fox shock (2) bushing

bore. This should leave about 1/16th of an inch gap between

the shock (2) and the boss on the other side of the dogbone.

Insert a black nylon washer (11) within the 1/16th’’ gap and

center as close as possible with a screwdriver.

7

SHOCK ATTACHMENT Press the Fox pin (10) the rest of

the way through the shock (3) and into the other side of

the dogbone (2) boss. Press the pin (10) in until it is centered

in the assembly. This will leave about 1/6th’’ exposed on each

side of the dogbone (2) as seen in Figure 3b. Place a black

nylon washer (11) on each end of the exposed Fox pin (10).

These washers (10) will have to be held in place by hand in

one of the following procedures.

8

THREAD PREP Yeti recommends prepping all bolt threads

at once on your work bench with Loctite or grease. This will

ensure that all bolts are used in assembly. The medium

strength (blue) Loctite formula along with proper torque is

ideal to keep the bolts snug.

Figure 3a: Dogbone (2) and Shock (3)

Assembly with Fox Pin (10) and Black

Nylon Washers (11), exploded

Figure 3b: Dogbone (2) and Shock (3)

Assembly with Fox Pin (10) and Black

Nylon Washers (11), assembled

1

3

2

4