16

Setup-Fox RP23

SETUP SHOCK RP23

Setup-Fox DHX Air

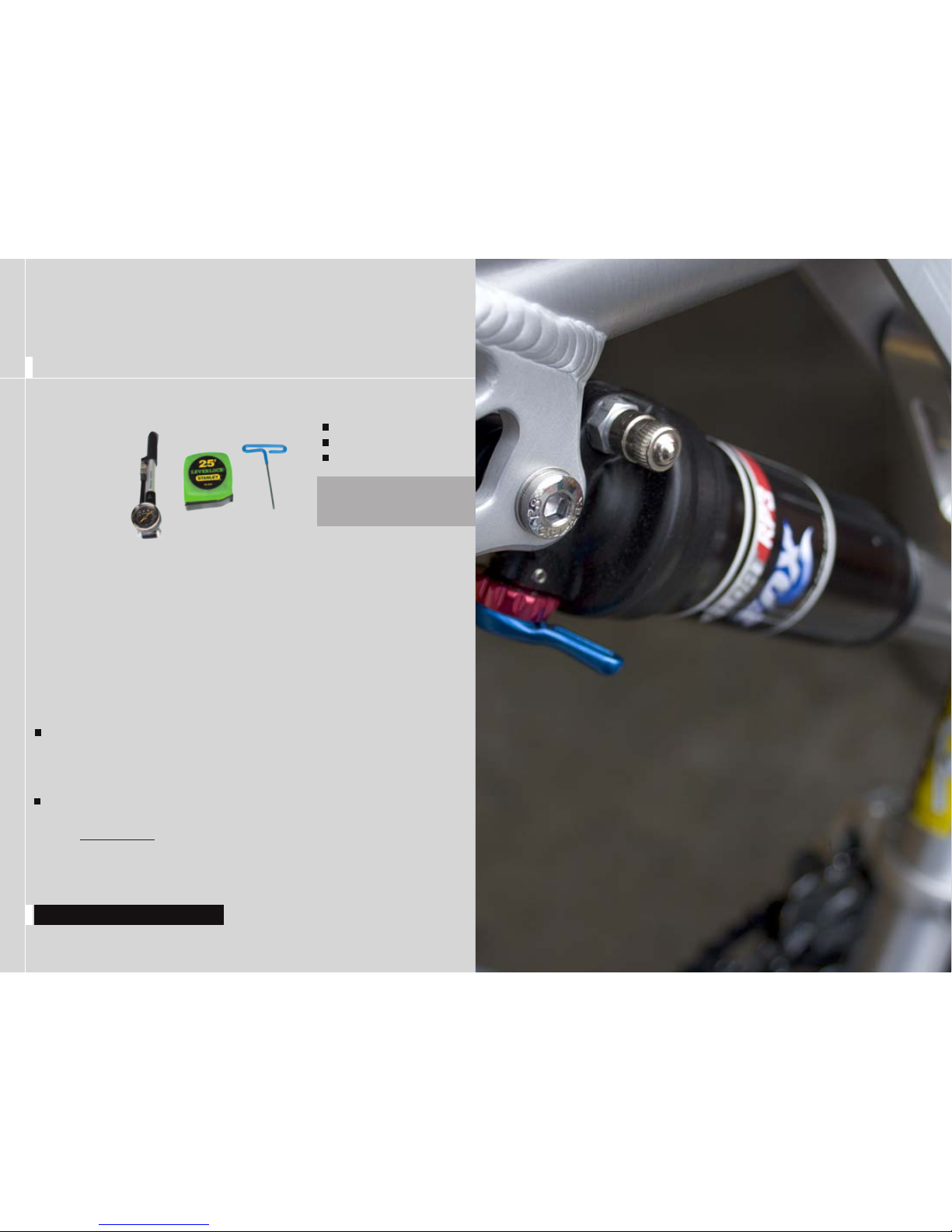

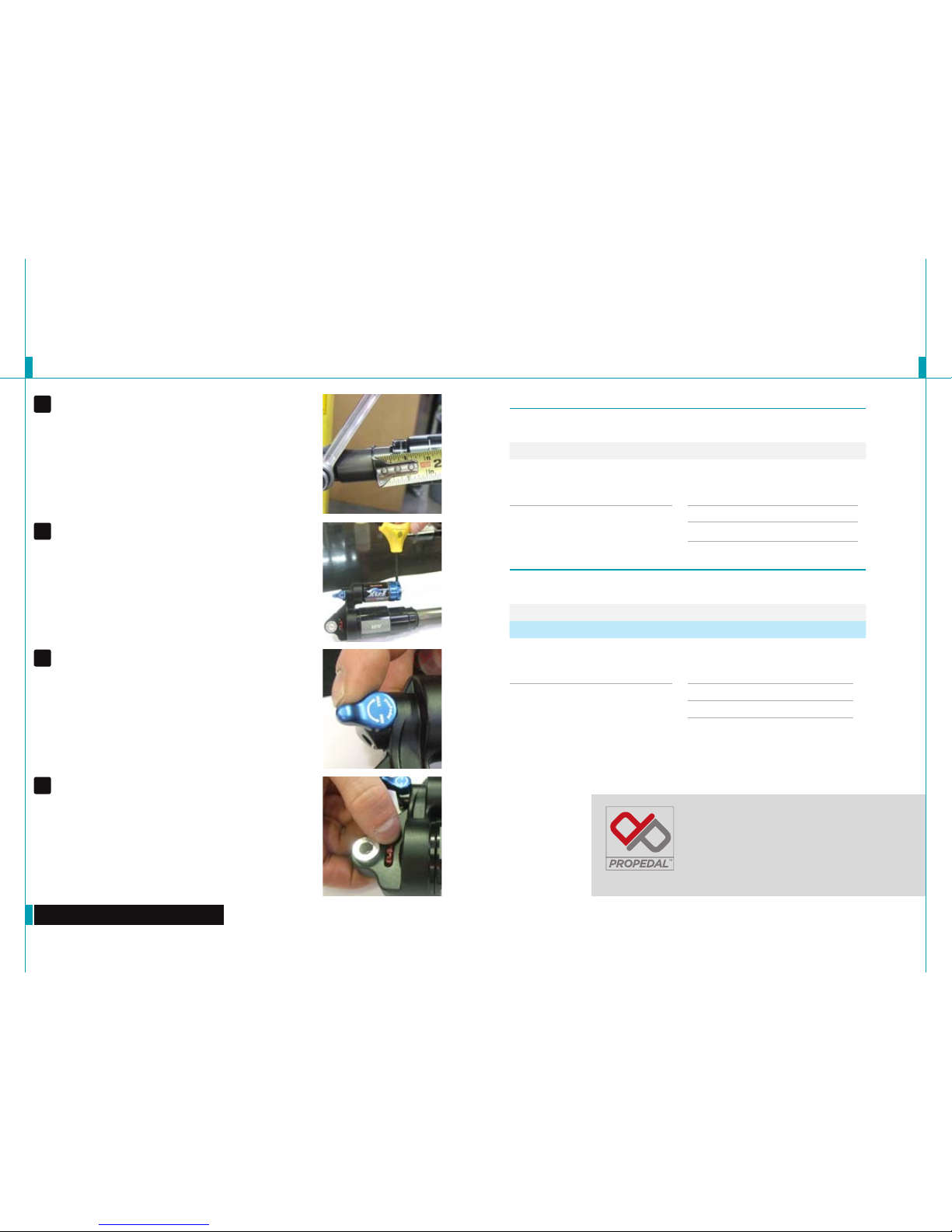

PRO-PEDAL The pro-pedal dampening has two settings and three

levels of adjustment and is controlled by the blue lever (formerly

the lock-out lever). The two settings are open and propedal. Use each

setting to adjust the shock for different riding conditions and situations. For

example use propedal for riding to the top of the mountain and then switch

to open for the descent.

The pro pedal knob has three different levels of dampening: (1) light, (2)

medium and (3) heavy pro-pedal. If the bike feels too firm, put it on a light

setting, and if it feels too sluggish, turn it to the stiffer setting.

AIR PRESSURE The main air spring controls the sag of the shock.

For the 575 to ride properly it is important to setup the shock with the

correct amount of sag. For general riding use 20-30% of the shock stroke

(5mm to 10mm). To increase sag reduce the main spring air pressure. To

reduce sag increase the main spring air pressure. Refer to the quick start

guide to get your starting air pressure.

SAG Once you have set your baseline air pressure you need to

measure the sag. To measure the sag slide the travel indicator

(O-Ring) up against the shock body. With a friend supporting the bike, sit

on the saddle (do not bounce) and allow your body weight to compress

the shock. Once you have compressed the shock, get off the bike and

measure the distance between the shock body and the new position of the

travel indicator (O-Ring). This is your sag. Refer to the guide below for the

percentage of sag equivalents for the measurement recorded.

Firm ride- 20-25% sag // Plush ride- 30% sag

REBOUND The rebound adjustment has 8-10 clicks of adjustment.

The rebound knob is the red adjustment dial located above your blue

pro-pedal adjustment lever. As a general rule, adjustments that are too fast

(counter-clockwise adjustment) will produce a springy ride with excessive

kick-up of the rear end causing a bucking sensation. Adjustments that

are too slow (clockwise adjustment) will cause packing of the rear wheel

indicated by a sluggish ride feeling ride.

Slower rebound- turn the knob clockwise

Faster rebound- turn the knob counter-clockwise

4

SETUP OVERVIEW The DHX 5.0 employs both speed sensitive rebound damping and positive sensitive

compression damping. There are three external adjustments that affect the compression and one external

adjustment for the rebound. The three compression adjustments are bottom-out resistance, boost valve and

pro-pedal. The pro-pedal controls the anti-bob properties of the shock or the first part of the shock’s stroke;

the bottom-out resistance controls the end of the shock stroke; and the boost valve damping links these

two adjustments together to create a seamless transition through the entire stroke. The boost valve also

decouples the pro-pedal and bottom-out resistance making these adjustments independent of each other.

AIR PRESSURE The main air spring controls the sag of the shock.

For the 575 to ride properly it is important to setup the shock with

the correct amount of sag. For general riding use 20-30% of the shock

stroke. To increase sag reduce the main spring air pressure. To reduce sag

increase the main spring air pressure. Refer to the quick start guide to get

your starting air pressure.

Firm Ride - 20-25% sag

Plush ride - 30% sag

1

Warning: Use of the shock with improper air pressure can cause loss of

dampening and malfunction of the shock.

BOOST VALVE The DHX 5.0 has an air pressure range of 125-200 psi,

and it must be pressurized for the shock to work properly. The Boost

Valve allows the Pro-Pedal (beginning compression) and the Bottom-Out

Resistance (ending compression) to work seamlessly together. Because

of this relationship the Boost Valve pressure affects both the Bottom-Out

Resistance and the Pro-Pedal Adjustments (see adjustment relation).

Lower pressures (125 – 150 psi)- Will decrease bottoming resistance and

lessen pro-pedal stiffness at a given setting.

Higher pressures (160 – 200 psi)- Will increase bottoming resistance and

stiffen pro-pedal at a given setting.

Warning: Use of the shock with improper air pressure can cause a loss

of dampening and shock malfunction could occur. Do not attempt to turn the

adjuster with more than 125 psi in the chamber.

2

1

2

3