The AC/DC Current Sensors (CT1000, CT200, CT60) are products of Yokogawa Test & Measurement

Corporation. Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document No. Description

PIM 113-01Z2 List of worldwide contacts

Safety Precautions

Make sure to observe the following safety precautions when handling the current sensor. YOKOGAWA assumes

no liability for the customer’s failure to comply with these safety precautions. Before you use the current sensor,

read the measuring instrument’s manual to fully acquaint yourself with its specifications and handling.

The following symbols are used on this instrument.

Warning: handle with care. Refer to the user’s manual or service manual. This symbol

appears on dangerous locations on the instrument which require special instructions for

proper handling or use. The same symbol appears in the corresponding place in the manual

to identify those instructions.

Risk of electric shock

Hot surface

Make sure to observe the following safety precautions to prevent electric shock, personal

injury, or damage to the instrument.

WARNING

• Beware of electric shock.

• Do not perform measurement if the case is damaged.

• Do not operate the device with wet hands, in a rainy or humid environment, or if any

water droplets are visible on it.

• Condensation may appear if sudden changes in temperature occur. If this happens, let

the device acclimatize to the new temperatures for at least one hour, then refrain from

using the device until confirming that there is no condensation.

• Do not disassemble the device.

The device should be disassembled by qualified personnel only.

• Use the correct power supply.

Ensure that the source voltage matches the voltage of the power supply before turning

the power ON.

• Do not use uninsulated measurement conductors or cables.

Use conductors or cables with reinforced insulation.

• Make sure that the surface temperature of measurement conductors is within the

device's operating temperature range.

• Although it is well-insulated, do not touch the device or secondary output cable

while voltage is being applied to the primary conductor.

• Connect the secondary signal output before supplying power to the device.

• Do not disconnect the secondary output while power is being supplied to the device

to prevent electric shock or damage to the instrument.

• Do not apply primary current before supplying power to the device to prevent

electric shock or damage to the instrument.

• Do not input excessive current as malfunction or damage may result.

• Do not allow vibrations to disturb the device after it has been set in place as damage

may result.

The following symbols are used in this manual.

Improper handling or use can lead to injury to the user or damage to the instrument.

This symbol appears on the instrument to indicate that the user must refer to the

user’s manual for special instructions. The same symbol appears in the corresponding

place in the user’s manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING Calls attention to actions or conditions that could cause serious or fatal injury to the

user, and precautions that can be taken to prevent such occurrences.

CAUTION Calls attention to actions or conditions that could cause light injury to the user or

damage to the instrument or the user’s data, and precautions that can be taken to

prevent such occurrences.

Note Calls attention to information that is important for proper operation of the instrument.

1. Description

This device is a current output type current sensor with a 1500: 1(for CT1000) 1000: 1(for CT200)

or 600: 1(for CT60) current transformation ratio that performs transformation on the primary current.

After familiarizing yourself with the performance and functions of this device, you will be able to use

it in conjunction with measuring instruments from YOKOGAWA.

2. Configuration

The current sensor consists of the following parts.

Standard parts

1. Current sensor

2. User’s manual

IM CT1000-01EN CT1000, CT200, CT60

AC/DC Current Sensor

User’s Manual

This manual. This manual explains the

handling precautions, basic usage, and

specifications of the probe.

IM CT1000-01JA CT1000, CT200, CT60

AC/DC Current Sensor

The Japanese version of the above manual

IM 00C01C01-01Z1 Safety Instruction Manual Safety manual (European languages)

The “EN” and “JA” in the manual numbers are the language code.

Contact information of Yokogawa offices worldwide is provided on the following sheet.

PIM 113-01Z2 Inquiries List of worldwide contacts

Thank you for purchasing the AC/DC Current Sensor (Model CT1000,CT200,CT60). To ensure correct

use, please read this manual thoroughly before beginning operation.

Please familiarize yourself with the functions and characteristics of the probe prior

to operation.After reading this manual, keep it in a safe place.

IM CT1000-01EN

11th Edition

IM CT1000-01EN 1/2

Accessories (Sold Separately)

The optional accessories below are available for purchase separately. Use the accessories

specified in this manual. Moreover, use the accessories of this product only with Yokogawa products

that specify them as accessories.

Output connector B8200JQ

Load resistors B8200JR

B8200JQ consists of a connector and attachment screws for connecting to the instrument. A

separate cable is required for making the connection.

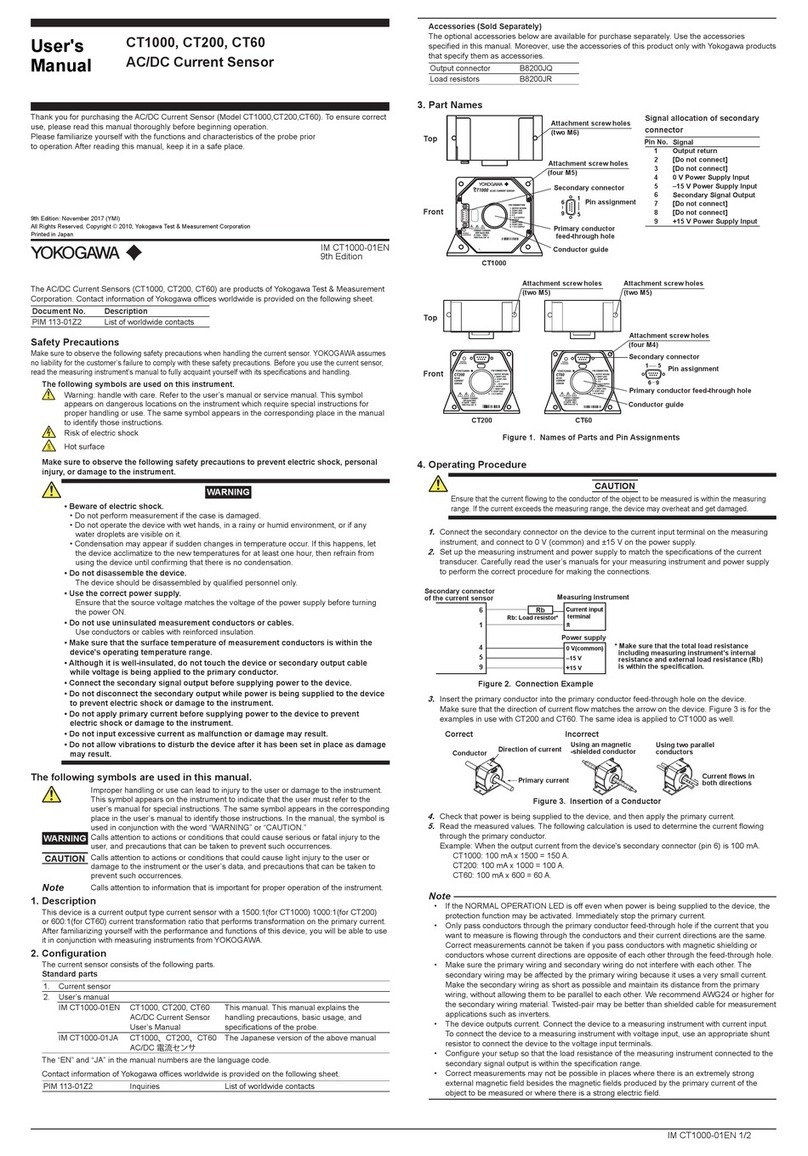

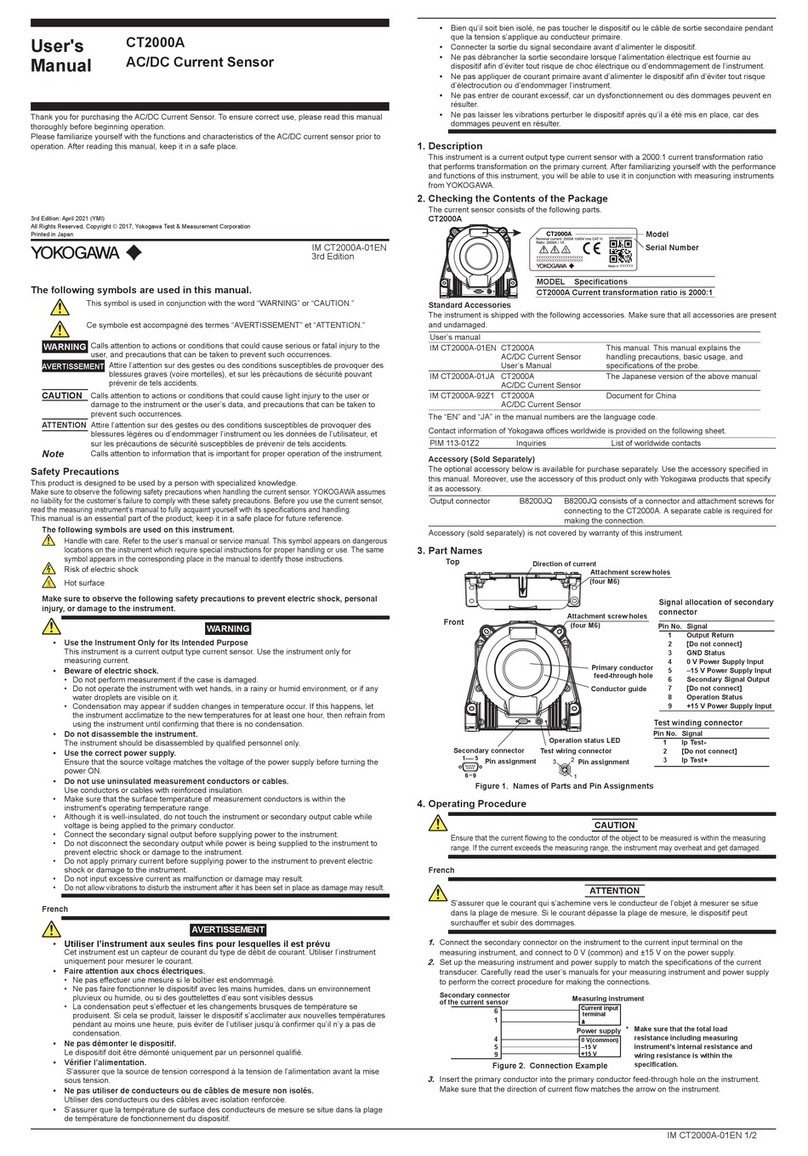

3. Part Names

Secondary connector

Primary conductor feed-through hole

Conductor guide

CT60CT200

1

5

6

9

CT1000

Front

Top

Front

Top

(two M5)

Attachment screw holes

(two M5)

Attachment screw holes

1 5

6 9

Pin assignment

Figure 1. Names of Parts and Pin Assignments

Primary conductor

feed-through hole

Conductor guide

Secondary connector

Pin assignment

Pin No.

1

2

3

4

5

6

7

8

9

Signal

Output return

[Do not connect]

[Do not connect]

0 V Power Supply Input

–15 V Power Supply Input

Secondary Signal Output

[Do not connect]

[Do not connect]

+15 V Power Supply Input

Signal allocation of secondary

connector

(four M5)

Attachment screw holes

(two M6)

Attachment screw holes

(four M4)

Attachment screw holes

4. Operating Procedure

CAUTION

Ensure that the current flowing to the conductor of the object to be measured is within the measuring

range. If the current exceeds the measuring range, the device may overheat and get damaged.

1.

Connect the secondary connector on the device to the current input terminal on the measuring

instrument, and connect to 0 V (common) and ±15 V on the power supply.

2.

Set up the measuring instrument and power supply to match the specifications of the current

transducer. Carefully read the user’s manuals for your measuring instrument and power supply

to perform the correct procedure for making the connections.

Secondary connector

of the current sensor

4

5

9

6

Power supply

0 V(common)

–15 V

+15 V

Rb Current input

terminal

Measuring instrument

Rb: Load resistor*

Figure 2. Connection Example

* Make sure that the total load resistance

including measuring instrument's internal

resistance and external load resistance (Rb)

is within the specification.

1

3.

Insert the primary conductor into the primary conductor feed-through hole on the device.

Make sure that the direction of current flow matches the arrow on the device. Figure 3 is for the

examples in use with CT200 and CT60. The same idea is applied to CT1000 as well.

Correct

Conductor

Primary current

Incorrect

Using a magnetic

-shielded conductor

Using two parallel

conductors

Current flows in

both directions

Direction of current

Figure 3. Insertion of a Conductor

4.

Check that power is being supplied to the device, and then apply the primary current.

5.

Read the measured values. The following calculation is used to determine the current flowing

through the primary conductor.

Example: When the output current from the device's secondary connector (pin 6) is 100 mA.

CT1000: 100 mA x 1500 = 150 A.

CT200: 100 mA x 1000 = 100 A.

CT60: 100 mA x 600 = 60 A.

Note

• If the NORMAL OPERATION LED is off even when power is being supplied to the device, the

protection function may be activated. Immediately stop the primary current.

• Only pass conductors through the primary conductor feed-through hole if the current that you

want to measure is flowing through the conductors and their current directions are the same.

Correct measurements cannot be taken if you pass conductors with magnetic shielding or

conductors whose current directions are opposite of each other through the feed-through hole.

• Make sure the primary wiring and secondary wiring do not interfere with each other. The

secondary wiring may be affected by the primary wiring because it uses a very small current.

Make the secondary wiring as short as possible and maintain its distance from the primary

wiring, without allowing them to be parallel to each other. We recommend AWG24 or higher for

the secondary wiring material. Twisted-pair may be better than shielded cable for measurement

applications such as inverters.

•The device outputs current. Connect the device to a measuring instrument with current input.

To connect the device to a measuring instrument with voltage input, use an appropriate shunt

resistor to connect the device to the voltage input terminals.

•Configure your setup so that the load resistance of the measuring instrument connected to the

secondary signal output is within the specification range.

•Correct measurements may not be possible in places where there is an extremely strong

external magnetic field besides the magnetic fields produced by the primary current of the

object to be measured or where there is a strong electric field.

CT1000, CT200, CT60

AC/DC Current Sensor

11th Edition: March 2022 (YMI). All Rights Reserved. Copyright © 2010 Yokogawa Test & Measurement Corporation. Printed in Japan

*IM CT1000-01EN/11*