The edge

of

the knife should keep a clearance about 0.4-0.Smm with the side

of

presser foot(figure

l)

This clearance is an important factor for assuring skiving quality, The edge

of

the knife will get dull

through skiving, and need to regring. After several times or long time regrinding the relative position

of

the edge

of

the knife to the feeding grinding wheel and the side

of

presser foot will change, and can

be

m.ade

up by means

of

adjusting the axial position

of

the knife.

JS-801:The circular knife adjustment consists

of

precise worm and worm wheel whick can make

micro-adjusting by means

of

tui:t_ting

the adjusting handle

of

the knife. Turn clockwise to increase the

clearance and tum it counterclockwise

··o

decrease the clearance.(see Figure 2)

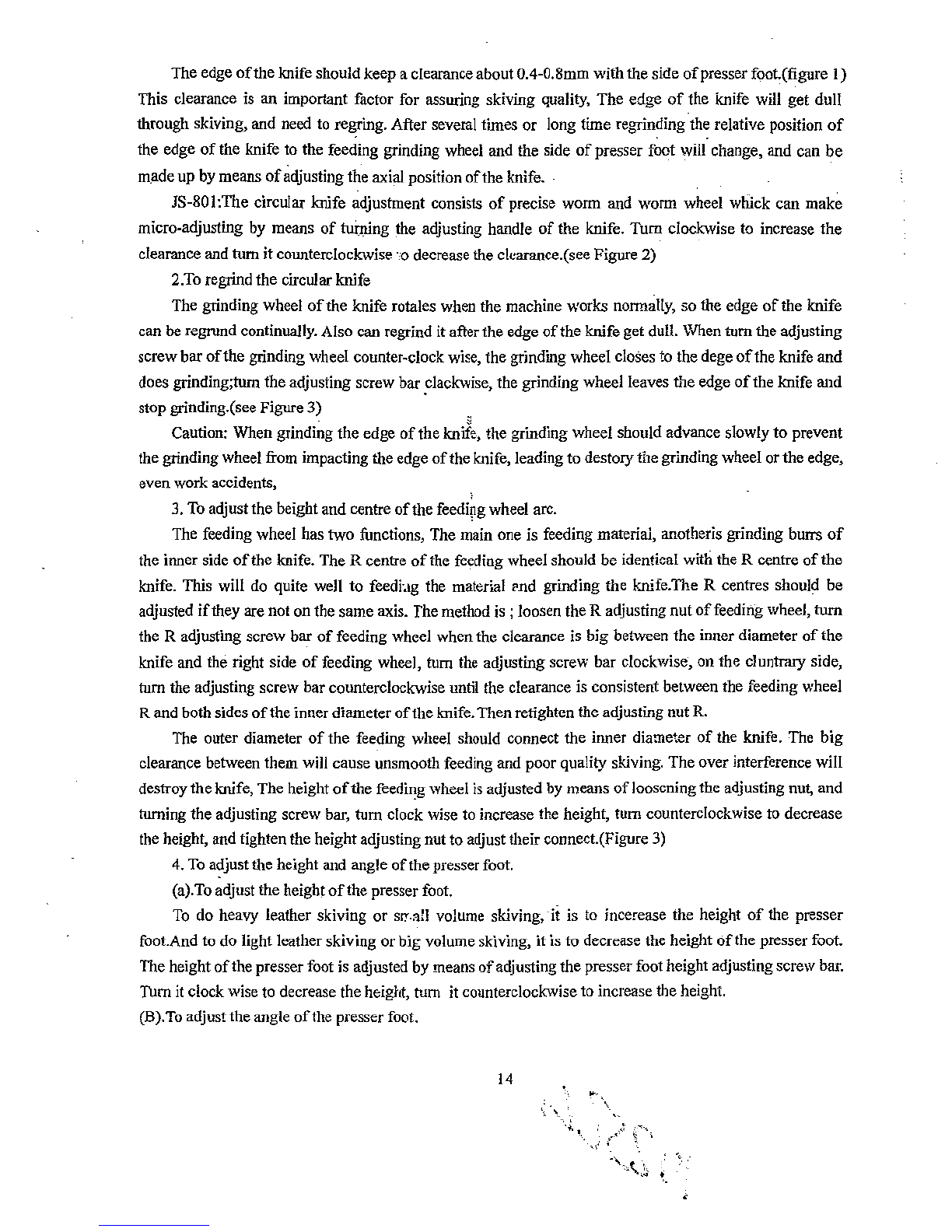

2.To regrind the circular knjfe

The grinding wheel

of

the knife rotales when the machine works normally, so the edge

of

the knife

can

be

regrund continually. Also can regrind it afterthe edge

of

the knife get dull. When

tum

the adjusting

screw bar

of

the grinding wheel counter-clock wise, the grinding wheel closes to the dege

of

the knife and

does grinding;turn the adjusting screw bar

_clackwise,

the grinding wheel leaves

t.t'l.e

edge

of

the knife and

stop grinding.(see Figure

3)

Caution: When grinding the

edge

of

theknife, the grinding wheel should advance slowly

to

prevent

the grinding wheel from impacting the edge

of

the knife, leading to destorythe grinding wheel orthe edge,

even work accidents,

3.

To

adjust the beight and centre

of

the

feedi~g

wheel arc.

The feeding wheel has two functions, The main one is feeding material, anotheris grinding burrs

of

the inner side

of

the knife. The R centre

of

the feeding wheel should be identical with the R centre

of

the

knife. Tills will do quite well

to

feedi'.lg the material

md

grinding the knife.The R centres should be

adjusted

if

they are not on the same axis.

The

method

is;

loosen the R adjusting nut

of

feeding wheel,

turn

the R adjusting screw bar

of

feeding wheel when the clearance

is

big between the inner diameter

of

the

knife and the right side

of

feeding wheel, tum the adjusting screw bar clockwise,

on

the cluntrary side,

turn the adjusting screw bar counterclockwise until the clearance is consistent between the feeding wheel

Rand

both sides

of

the inner diameter

of

the knife.Then retighten the adjusting nut

R.

The outer diameter

of

the feeding wheel should connect the inner diameter

of

the knife. The big

clearance between them will cause unsmooth feeding and poor quality skiving. The over interference will

destroythe knife, The height

of

the feedif!g wheel

is

adjusted by means

of

loosening the adjusting nut, and

turning the adjusting screw bar, tum clock wise to increase the height, turn counterclockwise

to

decrease

the height, and tighten the height adjusting nut to adjust their connect.(Figure 3)

4.

To

adjust the height

and

angle

of

the presser foot.

(a).

To

adjust the height

of

the presser foot.

To

do heavy leather skiving or

srr.n!J

volume skiving, ii is to incerease the height

of

the presser

foot.And to do light leather skiving or big volume skiving, it is to decrease the height

of

the presser foot.

The height

of

the presser foot

is

adjusted by means

of

adjusting the presser foot height adjusting screw bar.

Tum it clock wise to decrease the height, tum it counterclockwise to increase the height.

(B).

To

adjustthe angle

of

the presser foot.

14 •

...

'·

,.•" '

';

•

,,.-

< • -

..

:

From the library of: Superior Sewing Machine & Supply LLC