FV563 Rev. - 12/2/14

Page9

OPERATION

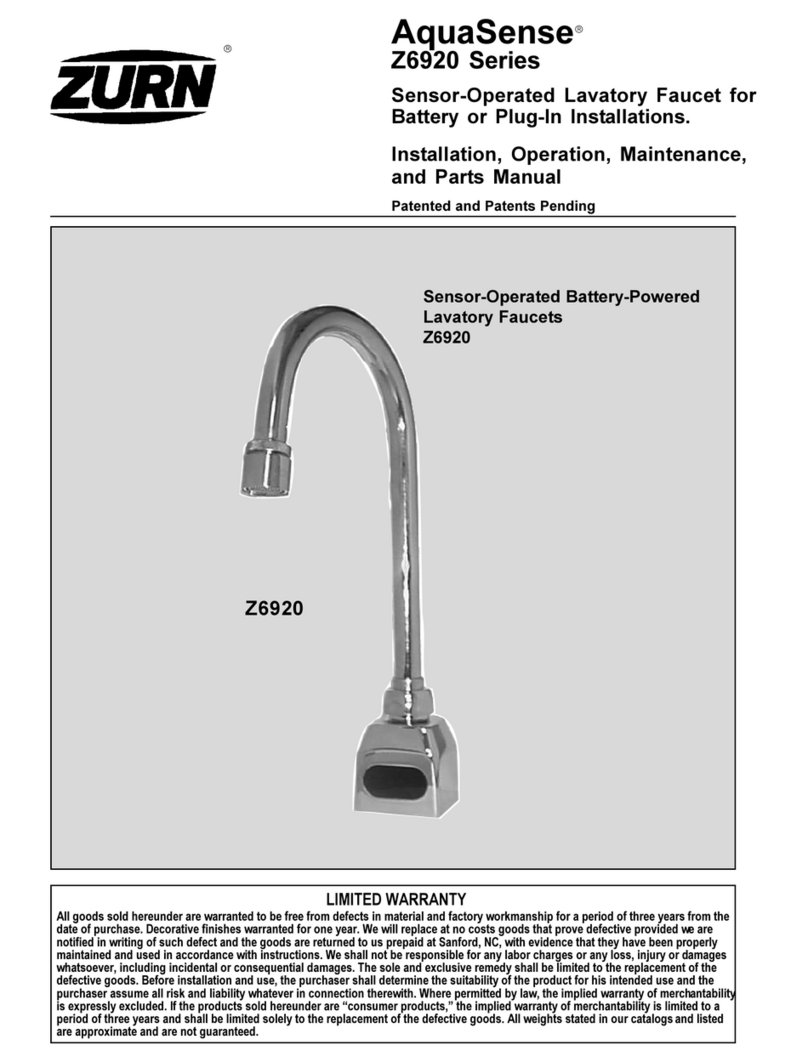

1.) Invisible light rays are continually emitted from the faucet

sensor.

2.) When the user’s hands come into range of the sensor’s

detection zone (factory set at approximately 6”), the beam is

reflected back to the sensor’s reciever and converted to a low

voltage electrical signal activating a solenoid valve.

3.) After the user removes their hands, the absence of reflected

light stops the low voltage electrical signal, closing the valve.

The circuit automatically resets for the next user.

4.) If an object is in view continuously for thirty seconds, the

faucet will automatically shut off. The faucet will remain off until

the object is removed. After the object is removed, the faucet

functions normally.

Aqua-FITTM is a trademark of Zurn Industries, LLC.

Printed in the U.S.A.

TROUBLESHOOTING GUIDE

SPECIFICATION

Voltage:

Sensor Range:

Operating Water

Pressure:

Ambient

Temperature:

Operational Water

Temperature:

Aerator:

6 VDC

(4“AA”Alkaline)

6” Approximate from Water Outlet

20-80 psi

32ºF to 122ºF (0ºC to 50ºC)

35°F to 140°F (2°C to 60°C)

1.5 GPM Vandal-Resistant (Standard)

ZURN INDUSTRIES, LLC.

♦♦

♦♦

♦

COMMERCIAL BRASS OPERATION

♦♦

♦♦

♦

5900 ELWIN BUCHANAN DRIVE

♦♦

♦♦

♦

SANFORD NC 27330

Phone: 1-800-997-3876

♦♦

♦♦

♦

Fax: 919-775-3541

♦♦

♦♦

♦

World Wide Web: www.zurn.com

In Canada: ZURN INDUSTRIES LIMITED

♦♦

♦♦

♦

3544 Nashua Drive

♦♦

♦♦

♦

Mississauga, Ontario L4V1L2

♦♦

♦♦

♦

Phone: 905-405-8272 Fax: 905-405-1292

POTENTIAL SITUATIONS POSSIBLE CAUSES SUGGESTED SOLUTION TIPS

Solenoid is not connected properly Place hands in sensor range. If clicking occurs, solenoid is connected

correctly. If no clicking occurs, disconnect the sensor cable from the

black box and w ait 15 sec before reconnecting. Once reconnected try

activating again.

Batteries are low on pow er Change out batteries

Sensor and electronic connector cable has

bent or broken pins Check to see if pins are missing, bent, or broken. If yes, then the

electronic box needs replaced

Solenoid is lodged w ith debris Check solenoid for debris and clean if necessary and reassemble

If faucet is hardw ired, could have voltage

range issues Check voltage levels and adjust if necessary to fallw ithin

recommended ranges.

Sensor lens could be obstructed by

environmental factors such as high reflective

surfaces or bright lighting conditions

If this is the case, then adjust the dip sw itch settings for sensor

resolution per the diagramin the installation manual(sw itches 7 and 8)

Sensor lens could have surface damage,

scratches, or deposit build ups fromchemical

cleaners

Inspect the sensor lens underneath the spout tip. May require cleaning

(damp rag) or replacement

Remove the battery tray and inspect for visual signs of rust, water,

debris. Replace battery tray if these symptoms are found.

Remove battery tray, if no visual signs can be detected, try using a

metallic object to tap the coils to exhaust any fault charges. Reassemble

Sensor faucet does not

activate after initial installation Sensor lens may not have had enough time to

calibrate prior to a user or target trying to

initiate activation

Disconnect the sensor and electronic box cables and wait for 15

seconds. Reconnect the cables, but allow for another 15 seconds

before placing hands or a target within the sensor range. You should

hear a click of the solenoid once calibration is complete.

Solenoid is lodged w ith debris Check solenoid for debris and clean if necessary and reassemble

Sensor and electronic connector cable has

bent or broken pins Check to see if pins are missing, bent, or broken. If yes, then the

electronic box needs replaced

If this is the case, then adjust the dip sw itch settings for sensor

resolution per the diagramin the installation manual(sw itches 7 and 8)

Loosen the mounting nuts and try sliding the faucet back in the lavatory,

sink, or counter top holes back tow ards the wall and retightening. Could

be detecting the grid drain in the sink bow l.

Mounting hardw are is not tightened sufficiently

(faucet shank, electronic box, supply hoses,

etc)

Check and ensure the nuts and joints are tight and secure fromthe

supply stop allthe way to the faucet shank.

Missing the w asher located in the solenoid box

nut where it assembles to the faucet shank. Make sure w ater supply stops are shut off. Check to ensure the

w asher is installed. If not, need to replace w ith a new washer.

Sensor faucet is leaking

underneath the sink or

counter

Sensor faucet is not

activating or running

Coils in battery tray are promoting a voltage

drain

Faucet runs continuously

(longer than the selected time-

out that is programmed)

Sensor faucet is experiencing

randomactivations when a

user or target is not within

sensing range

Sensor lens could be obstructed by

environmental factors such as high reflective

surfaces or bright lighting conditions