3. PLACEBODY(ITEM #9)INTO SINKFROM UNDERSIDEAND PLACEWASHER(ITEM #3B) ANDRETAINING RING(ITEM

#3A)ONTOSHANKS ABOVESINK TOP.

4. REASSEMBLECARTRIDGE CAP(ITEM #1)TO BODY (ITEM#9).

5. HANDTIGHTENNUTS(ITEM #9A)TOSECUREASSEMBLYTO SINK.DO NOT OVERTIGHTEN.

6. PLACE GASKET (ITEM #7A) BETWEEN TEE (ITEM #7D) & SHANK. SECURE TEE TO SHANK WITH NUT (ITEM #7C).

7. TIGHTEN ESCUTCHEONS (ITEM #2) BODY (ITEM #9) TO SECURE BODY TO SINK.

8. INSTALL SPOUTINTO BASEAND TIGHTEN NUT(SEE VIEWS FOR SWING/RIGID CONNECTION). SCREW HANDLES

ONTOCARTRIDGESTEMS (ITEMS #5AND #6)ANDINSERTINDEXBUTTONS.

9. PROCEEDTO“FINISHINGINSTALLATION”ALLMODELSSECTION

Z83100-HS (SEE FIGURE 4)

1. FULLY THREAD MOUNTING NUT (ITEM #7C) ONTO DIVERTER TEE (ITEM 6D). PLACE WASHER (ITEM #7B)AND

FRICTIONGASKET (ITEM#7A) ONTODIVERTERTEE (ITEM#6D).

2. PLACE DIVERTER TEE (ITEM #6D) INTO SINK FROM UNDERSIDEAND THREAD ESCUTCHEON (ITEM #6A) ON SO

THERE’SAPPROXIMATELY1”OFTHREADS STICKING OUTABOVEESCUTCHEON (ITEM#6A).

3. REMOVEBODYASSEMBLY(ITEM#9) FROMPACKAGINGAND PLACEWASHER (ITEM#3C) ONTOEND FITTINGS,

SCREW NUTSALLTHE WAYDOWN ON THREADS.

4. PLACEBODY(ITEM #9)INTO SINKFROM UNDERSIDEAND PLACEWASHER(ITEM #3B) ANDRETAINING RING (ITEM

#3A)ONTOSHANKS ABOVESINK TOP.

5. HANDTIGHTENNUTS(ITEM #9A)TOSECUREASSEMBLYTO SINK.DO NOT OVERTIGHTEN.

6. TIGHTEN ESCUTCHEONS (ITEM #1) ONTO CARTRIDGE CAP (ITEM #2) TO SECURE BODY TO SINK.

7. INSTALL SPOUTINTO DIVERTER TEEANDTIGHTEN NUT (SEE VIEWS FOR SWING/RIGID CONNECTION). SCREW

HANDLES ONTO CARTRIDGE STEMS (ITEMS #4AND #5)AND INSERT INDEX BUTTONS.

8. BACK OFF ESCUTCHEON (ITEM #6A) UNTILSNUGAGAINST SPOUTNUT. TIGHTEN MOUNTING NUT (ITEM #7C) TO

SECUREDIVERTERTEEASSEMBLY(ITEM #6)ON SINK.

9. REMOVE HOSESPRAYASSEMBLY(ITEM #11) FROMPACKING. INSERTLOOSEWASHERINTO ENDOF HOSE.

ASSEMBLE HOSEAND SPRAYESCUTCHEON(ITEM #11A)ONTOSINK. INSERTHOSEAND SPRAY(ITEM#11B)

THROUGHESCUTCHEON (ITEM#11A) FROMTOPOFSINKANDATTACHTODIVERTERTEE(ITEM #6D).

10.PROCEEDTO“FINISHINGINSTALLATION”ALLMODELSSECTION

“FINISHINGINSTALLATION”ALLMODELS

1. ATTACH LAVATORYSUPPLIESTOFAUCETUSING COUPLINGNUT(ITEM #10).

2. OPTIONAL - POP-UP (-P) / GRID STRAINER (-G) / HANDICAP OFFSET GRID DRAIN (-GH) (NOT AN OPTION FOR

Z80000-HS) INSTALL POP-UP OR GRID STRAINER IN SINK OUTLETAND PLUMB WASTE CONNECTION.

3. INSTALLAERATORONTOSPOUT ENDAND HANDTIGHTEN. ITMAYBE NECESSARYTOUNSCREWANDCLEAN

AERATORATSTART-UP.

4. TURNWATER SUPPLY ONANDOPERATE FAUCETCHECKING FORLEAKS.

5. ITMAYBENECESSARYTOSHUTWATER OFFAND REMOVECARTRIDGESTOCLEAN SUPPLYLINES. CARTRIDGES

CANBE REMOVEDBY FIRSTREMOVINGTHEHANDLES. COLOR INDEXESCAN BEREMOVED BYINSERTINGAPIN

INTOTHE HOLE ON THE UNDERSIDE OF THE HANDLE. AFTER THE HANDLES HAVE BEEN REMOVED, UNSCREW

ECUTCHEONS (ITEM #1)AND REMOVETHE CARTRIDGE CAPS (ITEM #2). PULLUP ON THE CARTRIDGE.

6. REPLACE CARTRIDGES IN BODYAND HAND TIGHTEN CARTRIDGE CAPS. PLACE HANDLES ON THE CARTRIDGE

STEMAND LOCATETHEMAS DESIRED.TIGHTENCARTRIDGECAPS.

7. REPLACE HANDLE SCREWS AND COLOR INDEX BUTTONS.

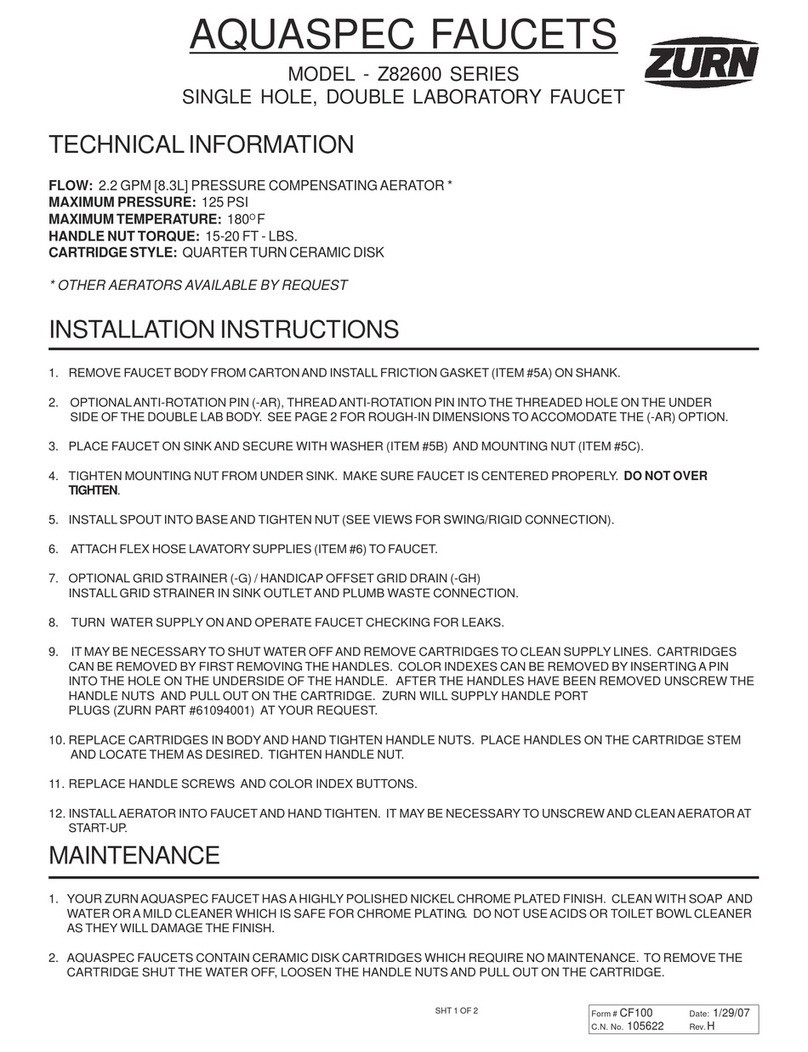

MAINTENANCE

1. YOURZURNAQUASPECFAUCETHASAHIGHLYPOLISHEDNICKELCHROME PLATEDFINISH. CLEAN WITHSOAP

AND WATER ORAMILD CLEANER WHICH IS SAFE FOR CHROME PLATING. DO NOT USEACIDS OR TOILETBOWL

CLEANERAS THEYWILLDAMAGETHE FINISH.

2. AQUASPEC FAUCETSCONTAINCERAMIC DISKCARTRIDGESWHICHREQUIRE NOMAINTENANCE. TOREMOVE THE

CARTRIDGE, SHUTTHE WATER OFF, LOOSEN THE HANDLE NUTSAND PULLUP ON THE CARTRIDGE.

REPLACEMENTPARTS

COLD WATER CARTRIDGE 59517003

HOTWATER CARTRIDGE 59517004

INDEXBUTTONS G60500

Form # CF169 Date: 9/3/08

C.N. No. 107787 Rev.F

PAGE 2 OF 4