Product Description and Speciications

• Easy to install black hardware

• Overall dimensions: 38" wide 24" high

• Minimum screen size of 12" wide 4" high per segment

• Custom sizing up to a 48" overall length and max 24" high,

available through your Sales Rep

• Ships lat

Flatness Tolerance

Screens shall not have distortion in the form of a wrinkle,

twist or scallop along the perimeter of the sheet. Overall

warp extending across the sheet is permitted to a maximum

of 9/32" (7.14 mm) for each 48" (1.2 m) or fraction thereof.

Screen is to be measured when laying horizontally under its

own weight on a lat continuous surface.

Features and Beneits

Cleaning Instructions

3form screens should be cleaned periodically. A regular,

seasonal cleaning program will dramatically help prevent

noticeable weathering and dirt build-up. 3form recommends

the use of the following common cleaning products: Windex,

Formula 409, Simple Green, Fantastik, Virex, 10:1 Water/Bleach

Solution.

Rinse screens with lukewarm water. Remove dust and dirt from

screens with a soft cloth or sponge and a solution of mild soap

and/or liquid detergent in water. A 50:50 solution of isopropyl

alcohol and water also works well. Rinse thoroughly with

lukewarm water.

Do:

• Always use a soft, damp cloth to blot dry. (Rubbing with

a dry cloth can scratch the material and create a static

charge)

Do not:

• Use scrapers or squeegees on screens

• Use scouring compounds, gasoline, benzene, acetone,

carbon tetrachloride, certain deicing luids, lacquer thinner

or other strong solvents

• Use highly alkaline or abrasive cleaning agents

• Rub with a dry cloth

Usage Limitations

Do not use cyanoacrylate or solvent type thread locking

materials with screens.

Design Options

Screens have been independently tested and meet 2018

International Building Code criteria.

Flammability and Smoke Test Results

- Building Code Approvals

F

Self Extinguishing

Design Options

Pass F

Pass CC

Result

ASTM D Smoke

Density

Test

ASTM D

F

Flame Class - HB

Pass

Pass

Pass F

Pass

Not more toxic

than wood

Class B: -

≤

Pass

ASTM D Self-ignition

UL

UPITT Mortality Test

ASTM E-

Flame Spread, /" thick

Smoke Generated

NFPA /" thickness

Available Finishes/Textures

3form Design Option Screens come standard with both a

front and back Sandstone surface inish (clear). Sandstone is

a durable surface inish that has a subtle grainy texture with a

slightly frosted look. Additional Material Finishes include Hem,

Mesh and Spider. White fabric versions are shown below. See

www.3-form.com/Elements for all [Hem/Mesh] color options.

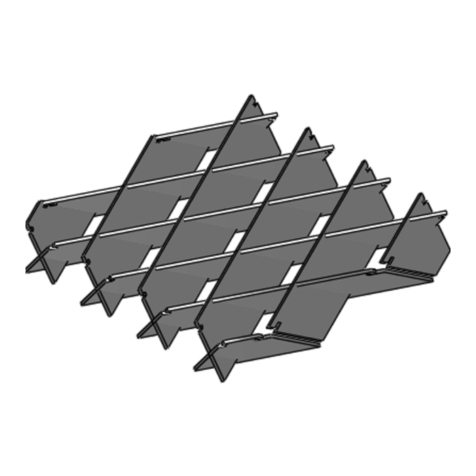

Hem Mesh SpiderClear

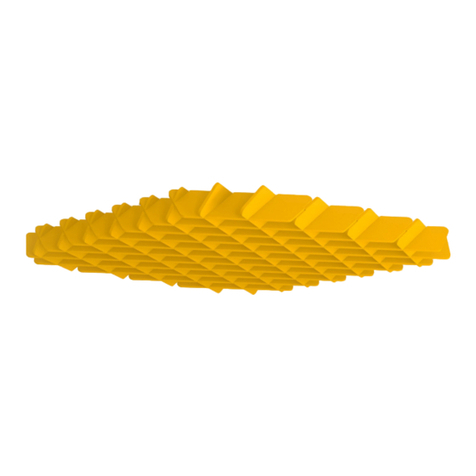

Screens can be speciied in 15 Sola Felt options.

Cast

Dusk

Mineral

Aries

Driftwood

Emerald

Nightfall

Admiral

Citrine

Ebony

Nickel

Armor

Dune

Jasper

Zinc

Available Finishes

• Available in 3/8" (9.53mm) Sola Felt

• NRC Rating of 0.35 (Alpha W .25H)

Sound Absorption Test Results

Noise Reduction Coeicient

Test-ASTM C- Result

Alpha-W

Cleaning Instructions

To remove airborne debris and dust, 3form

recommends to periodically vacuum Felt Screens. The

slight shedding of ibers from the Felt is normal and not

indicative of any defect.

To treat liquid stains, remove spills immediately using

a clean damp cotton cloth or with detergent soap and

warm water. Carpet and fabric cleaners can usually

be used; always test an inconspicuous area before the

actual stain.

Do:

• Vacuum or use a soft brush to clean Felt Screens

Do not:

• Use strong solvents, highly alkaline or abrasive

cleaning agents

• Do not completely saturate module with cleaning

solution or water

Screens have been independently tested and meet 2018

International Building Code criteria.

Felt

Class A: -

Result

ASTM E-

Flame Spread, /" thick

Smoke Generated

Test

Flammability and Smoke Test Results

- Building Code Approvals

Clear Gloss Option

• Available in 1/4" (6.35mm) PETG Gloss

• Provides high impact resistance with glass-like

translucency

Available Textures

3form Desk Partition PETG Gloss is a clear material with a

high gloss inish on both the front and back surface that

provides clarity and unobstructed views.

Usage Limitations

Do not use cyanoacrylate or solvent type thread locking

materials with Desk Partition PETG Gloss.

Cleaning Instructions

3form Desk Partition PETG should be cleaned periodically.

A regular, seasonal cleaning program will dramatically help

prevent noticeable weathering and dirt build-up. 3form

recommends the use of the following common cleaning

products: Windex, Formula 409, Simple Green, Fantastik,

Virex, 10:1 Water/Bleach Solution.

Rinse screens with lukewarm water. Remove dust and dirt

from Desk Partition PETG with a soft cloth or sponge and

a solution of mild soap and/or liquid detergent in water. A

50:50 solution of isopropyl alcohol and water also works well.

Rinse thoroughly with lukewarm water.

Do:

• Always use a soft, damp cloth to blot dry. (Rubbing with

a dry cloth can scratch the material and create a static

charge)

Do not:

• Use scrapers or squeegees on Desk Partition PETG

• Use scouring compounds, gasoline, benzene, acetone,

carbon tetrachloride, certain deicing luids, lacquer

thinner or other strong solvents

• Use highly alkaline or abrasive cleaning agents

• Rub with a dry cloth

Screens have been independently tested and meet 2018

International Building Code criteria.

F

Self

Extinguishing

PETG Gloss

Pass F

Pass CC

Result

ASTM D

Smoke Density

Test

ASTM D

F

Flame Class - HB

Pass

Pass

Pass F

Pass

Not more toxic

than wood

Class B: -

≤

Pass

ASTM D

Self-ignition

UL

UPITT Mortality Test

ASTM E-

Flame Spread, /" thick

Smoke Generated

NFPA /" thickness

Flammability and Smoke Test Results

- Building Code Approvals

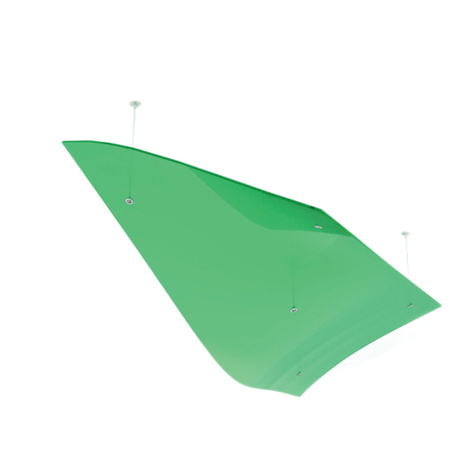

Acoustic Options

• Available in 1/4" (6.35mm) Design Material or Clear Material

• Contains 40% recycled content and a Declare Label

5

For more information, please visit 3-form.com or call 800.726.0126

JANUARY 2021 | MANRTG20068 | REV 001 © 2021 3form, Inc. All rights reserved.

Ready To Go

Installation Manual

SimpleSpec 200.68Desk Partition Sidetm