North American - ENG

Date Released:

05-22-18

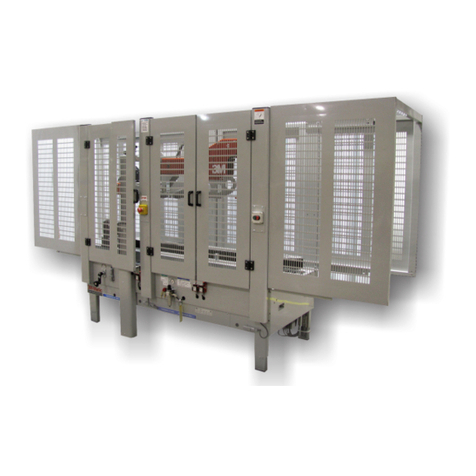

3M-Matic™7000r-7000r3 HS Pro - Type 11800

Page ix

44-0009-2152-6 / ECO# 0078045

Table of Contents (continued) — Manual 1:

7000r-7000r3 Random High Speed Case Sealer

(For Taping Head information, see Manual 2: AccuGlide™4 Taping Heads, 2 Inch or 3 Inch)

5. Shipment, Handling, and Storage

5.1 Packed Machine Shipment and Handling . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Overseas Shipment Packaging (Optional) . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Handling and Transportation of Uncrated Machine. . . . . . . . . . . . . . . . 19

5.4 Machine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. Unpacking

6.1 Uncrating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Packaging Materials Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7. Installation

7.1 Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7.2 Space Requirements for Machine Operation and Maintenance . . . . . . 21

7.3 Tool Kit Supplied with the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4 Machine Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.5 Plastic Ties Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.6 Assembly Completion / Machine Set-Up. . . . . . . . . . . . . . . . . . . . . 22 - 24

7.7 Infeed Conveyor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.8 Centering Guides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.9 Tape Leg Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.10 Electrical Connection and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.11 Initial Start-Up of Case Sealer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.12 Controls, Valves, Switch Locations . . . . . . . . . . . . . . . . . . . . . . . . . 27 - 29

7.13 Box Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.14 Taping Heads Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.15 Preliminary Electric Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.16 Main Power Machine Connection and Inspection . . . . . . . . . . . . . . . . . 30

7.17 Tape Application Monitor Installation (Optional) . . . . . . . . . . . . . . . . . . 31

8. Theory of Operation

8.1 Air Supply / Starting Machine / Machine Operation. . . . . . . . . . . . . . . . 32

8.2 Photo Sensors / Raising Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 - 34

8.3 Tape Application Monitor Operation (Optional) . . . . . . . . . . . . . . . . . . . .35

8.4 Tape Application Monitor Dispensing/Low Tape Sensors (Optional)36 - 37

8.5 Clearing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.6 Spacing of Boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

9. Controls

9.1 “Start/Stop” w/Reset Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.2 Emergency Stop Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.3 Main Air On-Off Valve / Regulator / Filter. . . . . . . . . . . . . . . . . . . . . . . . 38

9.4 Upper Drive Raising Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.5 Operating Upper Drive Raising Switch . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.6 Air Pressure Regulator / Upper Drive Counter BalanceAdjustment . . . . . . 39

9.7 Air Regulator/Gauge / Upper Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.8 Box Conveying / Tape SeatApplication. . . . . . . . . . . . . . . . . . . . . . . . . 40

10. Safety Devices

10.1 Blade Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.2 Emergency Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.3 Electric System / Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41