TABLE OF CONTENTS - MANUAL 1: 8000a-8000a3 Adjustable Case Sealer

(For Taping Head Information - See Manual 2 or 3: AccuGlide™ 3 Taping Heads - 2 Inch or 3 Inch)

8000a-8000a3 Adjustable Case Sealer Page

Cover Page

Replacement Parts and Service Information ........................................................................ i - ii

Table of Contents ................................................................................................................. iii - v

Acronyms and Abbreviations ................................................................................................ vi

1. Introduction

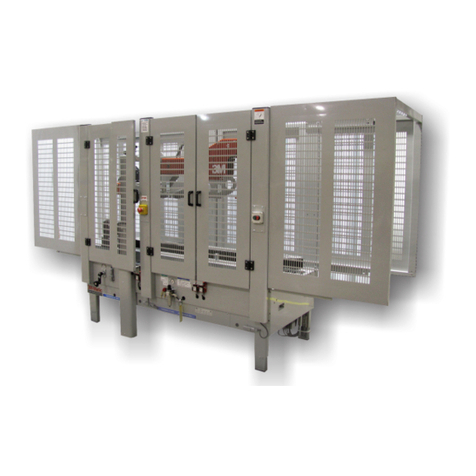

1.1 Manufacturing Specifications / Description / Intended Use .........................................1 - 2

1.2 How to Read and Use the Manual ............................................................................... 2

1.2.1 Importance of the Manual .................................................................................. 2

1.2.2 Manual Maintenance ......................................................................................... 2

1.2.3 Consulting the Manual ........................................................................................ 2

1.2.4 How to Update the Manual in Case of Modifications .......................................... 2

2. General Information

2.1 Identification Data ........................................................................................................ 3

2.2 After-Sale Service ........................................................................................................ 3

2.3 Warranty / Contents ..................................................................................................... 4

3. Safety

3.1 General Safety Information .......................................................................................... 5

3.2 Signal Words Explanation ............................................................................................. 5

3.3 Table of Warnings ......................................................................................................... 6 - 7

3.4 Operator’s Qualifications Definition ..............................................................................8

3.5 Number of Operators ................................................................................................... 8

3.6 Safe Use of the Machine Instructions .......................................................................... 8

3.7 Residual Hazards ..........................................................................................................8

3.8 Prevent Other Hazards - Recommendations and Measures ....................................... 8

3.9 Personal Safety Measures ........................................................................................... 8

3.10 Incorrect / Predictable Actions Not Allowed ..................................................................8

3.11 Operator's Required Skill Levels .................................................................................. 9

3.12 Component Locations .................................................................................................. 10

3.13 Table of Warnings and Replacement Labels ................................................................11

4. Technical Specifications

4.1 Power Requirements ...................................................................................................12

4.2 Operating Rate ............................................................................................................ 12

4.3 Operating Conditions ...................................................................................................12

4.4 Machine Noise Level ................................................................................................... 12

4.5 Set-Up Recommendations ......................................................................................... 12

4.6 Tape .............................................................................................................................13

4.7 Tape Width .................................................................................................................. 13

4.8 Tape Roll Diameter ......................................................................................................13

4.9 Tape Application Leg Length - Standard ......................................................................13

Tape Application Leg Length - Optional

4.10 Box Board ....................................................................................................................13

4.11 Box Weight and Size Capacities .................................................................................. 13 - 14

4.12 Machine and Packaged Machine Dimensions ............................................................. 15

iii 2014 June

8000a-8000a3 - NA