Page 4 of 28

P/N 595369-01 Rev B 07/19

WARNING

NO PERSONAL ALERT SAFETY SYSTEM,

RESPIRATOR OR COMBINATION OF PERSONAL

ALERT SAFETY SYSTEM AND RESPIRATOR,

BY THEMSELVES, CAN PROVIDE COMPLETE

PROTECTION IN DANGEROUS SITUATIONS.

FAILURE TO FOLLOW THE INSTRUCTIONS IN

THIS MANUAL AND THE REQUIREMENTS OF

AN ORGANIZED RESPIRATORY PROTECTION

PROGRAM MAY LEAD TO SITUATIONS THAT

COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING

USERS OF RESPIRATORS EQUIPPED WITH

A PASS DEVICE MUST BE AWARE OF THE

PROPER OPERATION OF THE PASS DEVICE.

IF THE GREEN LIGHT IS NOT FLASHING

NORMALLY, OR IF THE UNIT EXHIBITS ANY

OTHER SIGNS OF A MALFUNCTION WITHOUT

THE USER TAKING PROPER CORRECTIVE

ACTION, CIRCUMSTANCES THAT RESULT IN

SERIOUS INJURY OR DEATH MAY OCCUR.

WARNING

SEMS II PRO COMMUNICATES ONLY WITH

FIREFIGHTER RESOURCES (RESPIRATOR

USERS) USING A 3M SCOTT FIRE & SAFETY

SCBA EQUIPPED WITH THE SEMS II & SEMS

II PRO WIRELESS SCBA TELEMETRY SYSTEM

INTEGRATED INTO THE PASS DEVICE. OTHER

FIREFIGHTER RESOURCES WHO ARE NOT

USING A PROPERLY EQUIPPED 3M SCOTT

FIRE & SAFETY SCBA MAY BE ADDED FOR

ACCOUNTABILITY PURPOSES, BUT THEY

WILL NOT BE AUTOMATICALLY ACCESSIBLE

THROUGH THE COMMUNICATIONS

FUNCTIONS OF THE SYSTEM. FAILURE TO

RECOGNIZE THE STATUS OF FIREFIGHTER

RESOURCES MAY RESULT IN SERIOUS

INJURY OR DEATH.

• SEMS II Pro Control Console: Shoulder console equipped with a wireless

transceiver for data communication between the SCBA user and the Base

Station. The console includes the following features:

–A mechanical air supply gauge

–PASS device activation and reset buttons

–Icons indicating air supply, activation of a PASS alarm, initiation of

commands by the user or the incident commander, and Base Station

and two-way radio connection status

• SEMS II Gateway: USB transceiver that receives data from up to a

maximum of 75 SCBAs with SEMS II and SEMS II Pro Control Consoles

for visualization and management using the Base Station software, Scott

Connect Monitor.

• Scott Connect Monitor Software System2: Base station software that

monitors the status of SCBA users, including air supply levels, PASS

activation, and evacuation calls.

• SEMS II Repeater: A stationary unit that provides continuity of the mesh

network created by SCBAs equipped with SEMS II and SEMS II Pro.

• Programmable ID Tags and programming equipment

SEMS II Pro-equipped SCBAs provide continuous limited two-way communication

between the SCBA respirator Control Console and the Scott Connect Monitor

software. When logged on, all the SEMS II Pro units communicate to the Base

Station directly and/or through other logged on units forming a communications

"mesh network" to the Base Station. This extends the range for the units furthest

away from the Base Station. Because of this mesh network system, the signal

strength of each user may change as the network constantly readjusts to the

movement of the users.

No personal alert safety system, respirator, or combination of personal alert

safety system and respirator, by themselves, can provide complete protection in

dangerous situations. However, using an alarm and a respirator in accordance with

the requirements of an organized respiratory protection program is one of the many

safety precautions that should be taken to avoid personal injury or death.

SEMS II PRO COMPONENTS

SEMS II Pro, when added to a 3M Scott Fire & Safety SCBA, consists of a Sensor

Module assembly with a battery compartment mounted to the bottom of the

respirator backframe, a pressure gauge with transducer, and a Control Console

mounted on the wearer’s right shoulder strap at the pressure gauge location. The

PASS device requires six (6) AA batteries to operate the Sensor Module on the

backframe.

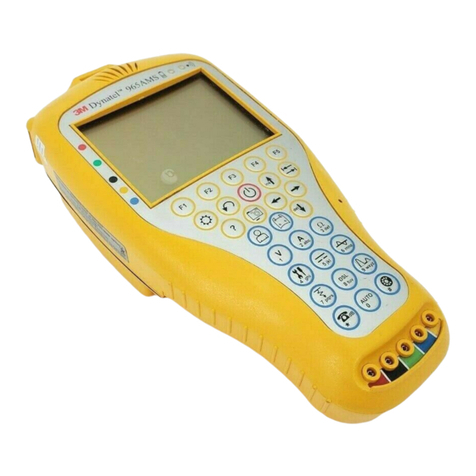

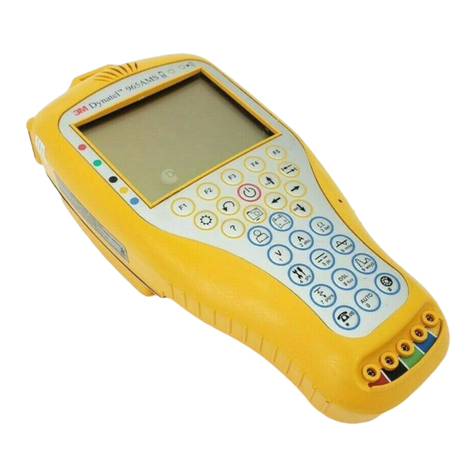

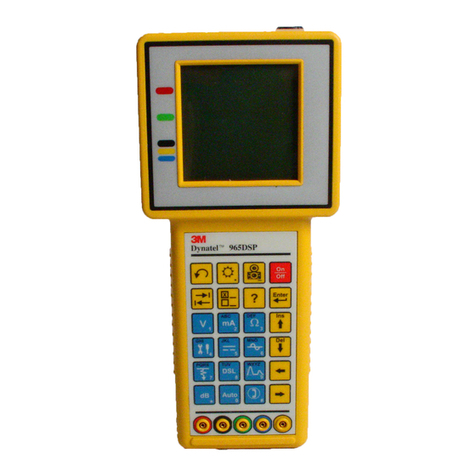

SEMS II PRO CONTROL CONSOLE

The SEMS II Pro Control Console is integrated

into the 3M Air-Pak X3 Pro SCBA as a part of the

remote air pressure gauge assembly which hangs

over the right shoulder of the respirator user. The

Control Console also operates the PASS device

intended to assist in locating a respirator user who

is incapacitated or in need of assistance.

The PASS device reaches FULL ALARM in 32

seconds. The Control Console has a set of status

lights, a dial air pressure gauge, and three control

buttons which can easily be pressed with gloved

hands. Power is supplied by batteries in

the battery compartment on the SCBA

backframe.

2Requires a Microsoft®Windows®-compatible PC (not included).

SEMS II PRO CONTROL

CONSOLE FOR 3M SCOTT

AIR-PAK X3 PRO SCBA

NOTE

SEMS II PRO-ENABLED SCBA'S HAVE BIDIRECTIONAL COMMUNICATION

CAPABILITIES AND CAN BOTH TRANSMIT AND RECEIVE DATA BETWEEN THE

CONTROL CONSOLE AND THE BASE STATION.

NOTE

SCOTT CONNECT MONITOR BASE STATION

SOFTWARE WILL NOT ALLOW MORE THAN 75

SEMS II- AND SEMS II PRO-EQUIPPED SCBA'S

TO CONNECT AT ONE TIME.