1

FOREWORD

Contact Information

Read all instructions and warnings before using. Keep these User Instructions for reference. If you have questions

regarding these products contact 3M Technical service.

In United States: In Canada:

Website: www.3M.com/workersafety

Technical Service: 1-800-243-4630

Website: www.3M.ca/Safety

Technical Service: 1-800-267-4414

System Description

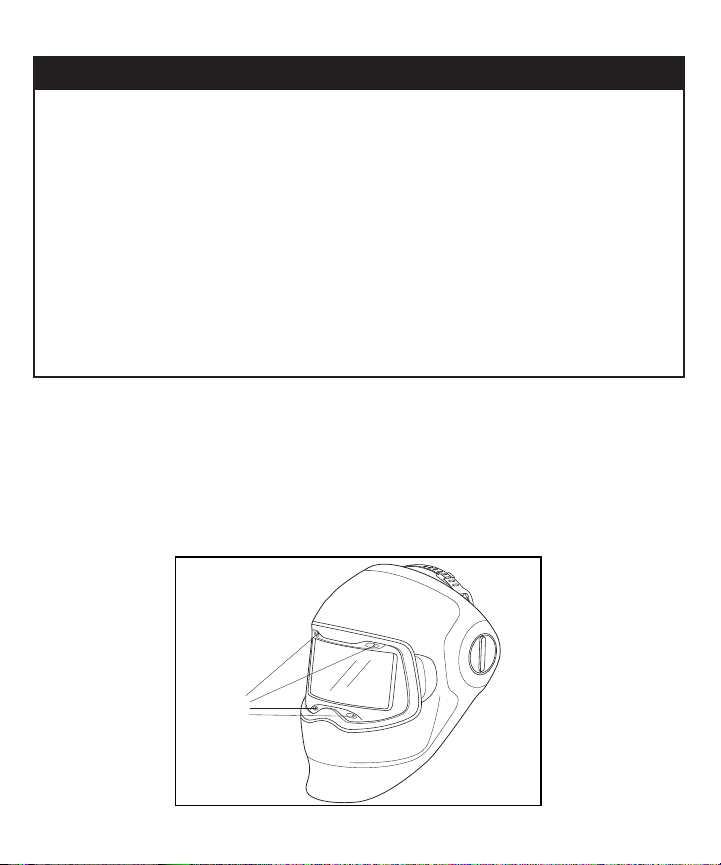

The 3M™ Speedglas™ Welding Helmet G5-02 helps protect the wearer’s eyes and face. It gives permanent

protection from sparks/spatter, UV and IR radiation resulting from certain arc/gas welding processes (shade 12

equivalent regardless of whether the lter is in the light or dark state or whether the auto-darkening function is

operational).

List of Warnings within these User Instructions

WWARNING

1. This product meets the requirements of certain industrial eyewear and face protection standards. It

does not provide complete eye and face protection from signicant impact and penetration and is not

a substitute for good safety practices and engineering controls. Misuse may result in serious bodily

injury or death. For correct use, consult your supervisor and User Instructions or contact 3M Technical

Service in the U.S.A. at 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

2. This product is not a respirator. Welding may produce high levels of welding fume or other airborne

contaminants which may exceed the Occupational Exposure Limit (OEL). As a result, users and their

employer must determine the expected hazards, and if needed select appropriate respiratory protection.

Properly selected, used, and maintained respirators in a full respiratory protection program help protect

against certain airborne contaminants by reducing airborne concentrations in the wearer’s breathing

zone below the OEL. Failure to use respirators or misuse of respirators may result in overexposure to

contaminants and lead to sickness or death.

3. Do not use any welding product without appropriate training.

4. When exposed to eye and face hazards, wear additional eye and/or face protectors appropriate to the

hazard. ANSI Z87.1 – Occupational and Educational Eye and Face Protection, incorporated by reference in

the OSHA Eye and Face Standard 29 CFR 1910.133, requires safety spectacles or goggles to be worn in

conjunction if the visor can be raised from the normal position during use. Failure to do so may result in

serious bodily injury or death.

5. Failure to follow these instructions may reduce the capability of the 3M™ Speedglas™ Welding

Helmet G5-02 shell to withstand impact and penetration and may result in serious bodily injury or death:

a. Use only the cleaning processes and agents described in these User Instructions to clean the shell.

b. Do not immerse in water or spray directly with liquids.

c. This welding helmet must not be painted or cleaned with solvents. Any decals applied to the

welding helmet must be compatible with the surface material and known not to affect adversely

the characteristic of the materials used in the welding helmet. Decals may affect the impact and

ammability characteristics of this welding helmet and prevent inspection for damage under decals.