Description:

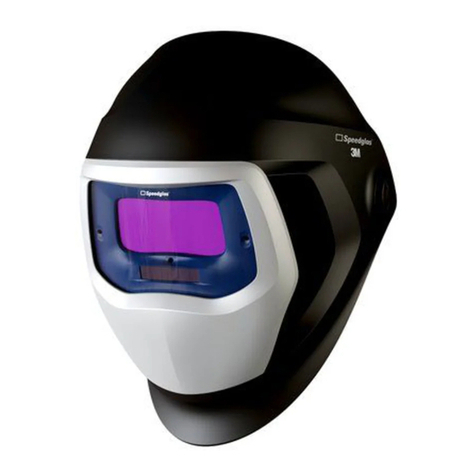

•Multi Protection - 5 levels of protection: Eye, Face, Head,

Respiratory and Hearing (optional accessory)

•Easy to operate and maintain.

•3M™ Speedglas™ 9100 Series Welding Filters and protection

plates

•Large Clear Visor (Same as 3M™ Speedglas™ 9100 FX Welding

Helmet)

•SideWindows

Applications:

The Speedglas 9100 MP Welding & Safety Helmet together with 9100

Series Welding Filters are designed for most welding processes, such

as MMA, MIG/MAG, TIG, plasma welding and oxyacetylene

welding/cutting.

The Speedglas 9100 MP Welding & Safety Helmet is excellent for

welding preparations such as grinding thanks to the large clear

viewing area. The Speedglas 9100 Welding & Safety Helmet is

designed to be used with 3M Air Delivery Units. See appropriate

reference leaflet for approved combinations.

Approvals:

The product meet the requirements of the European Community

Directive 89/686/EEC (Personal Protective Equipment Directive) and

is thus CE marked. The product comply with the harmonized

European Standards EN 175, EN 166 and EN 397. Certification under

Article 10, EC Type-Examination has been issued by INSPEC

International Ltd (Notified body number 0194). The complete 3M™

Speedglas™ 9100 MP Respiratory Systems complies with the

harmonized standards EN 12941 and EN 14594.

Speedglas 9100 MP Welding Helmet with powered air respirators or

supplied air regulators units marked CE0194 have had certification

under Article 10, EC-Type Examination and Article 11, EC Quality

Control issued by INSPEC international Ltd.

Speedglas 9100 MP Welding Helmet with powered air respirators or

supplied air regulators units marked CE0086 have had certification

under Article 10, EC-Type Examination and Article 11, EC Quality

Control issued by BSI.

Equipment Marking:

3M EN175B (medium energy impact B)

3M EN166B (medium energy impact B)

3M 1 BT N (1= optical class, BT=medium energy impact at extremes

of temperatures (-5°C and +55°C), N=Resistance to fogging)

3M EN12941 TH3 (nominal protection factor 500, higher strength

requirement for breathing hose and couplings)

3M EN12941 TH2 (nominal protection factor 50, medium strength

requirement for breathing hose and couplings)

3M EN14594 3B (nominal protection factor 200, higher strength

requirement)

3M Speedglas 9100 MP Welding Helmet with M-300 helmet shell

meet the requirements of EN 397

LD=Lateral Deformation, 440 V a.c.=Electrical Insulation

Additional markings on the product refer to other standards.

Mechanical Strength

EN 166, EN 175

No symbol Minimum robustness

S Increased robustness

F Low energy impact (45 m/s)

B Medium energy impact (120 m/s)

T Tested at extremes of temperature

(-5°C and +55°C)

Operating instructions:

Adjust the Speedglas 9100 MP Welding Helmet according to your

individual requirements to reach the highest comfort and protection.

(see fig B:1 - B:3).

Adjust and fit the air delivery unit as outlined in the appropriate User

Instruction. Adjust the face seal to suit the shape of the face. (see fig

G:7) If needed, lift the visor and adjust the airflow deflector. When fully

opened, more airflow is directed across the face. When partially

closed, a portion of the air is directed towards the visor. (see fig H:1)

It is important that the face seal is correctly mounted and fitted

to provide the correct protection factor. Do not remove the welding

helmet or turn off the air supply until you have vacated the

contaminated area.

Headtops used in aggressive environments or outside in direct

sunlight may need to be replaced more frequently than headtops used

occasionally indoors.

3M recommends a maximum life (shelf-life plus in-use life) of 3

years from the date of manufacture when stored in accordance with

the recommended storage conditions for the head protection part

(helmet).

Note: date of manufacture is molded on the helmet plastic part.

When working in environments with intense light radiation that

gives heat, environments with welding spatter or when high visibility is

required, 3M Speedglas Safety Helmet Cover shall be used.

Limitations of use:

Only use with original 3M spare parts and accessories listed in

the reference leaflet

and within the usage conditions given in the Technical Specifications.

The use of substitute components, decals, paint or other

modifications not specified in these user instructions might seriously

impair protection and may invalidate claims under the warranty or

cause the product to be noncompliant with protection classifications

and approvals.

3M™Speedglas™9100 MPWelding & Safety Helmet

Page 1 (of 2) © 3M 2015-02-12 All rights reserved

Rev 2013-02-05