3352423 (A3-D-P) Page 2 of 3

HP Gauge – Indicated pressure should not decrease more than 10bar in

1 minute.

Note: If fitted wth LPWWU, proceed to test the LPWWU. See the

following section. If not fitted, proceed as follows:

●Disconnect the male coupling (1) Fig. 2 from the female QRC of the

independent air supply. Press carefully the centre of the rubber cover

of the LDV to vent pressure.

●Type A and AE – Press the reset button of the LDV to switch ‘Off’

positive pressure.

6.5 LPWWU Test – if fitted

●Check that the valve of the independent air supply is ‘Closed’.

●Type A and AE – Fold the rubber cover from the front of lung demand

valve. Cover and seal the outlet of the LDV with the ball of the hand.

Press the centre of diaphragm then lift the hand to slowly vent

pressure.

●Type N – Carefully press the centre of the rubber cover to and slowly

vent pressure.

●Observe the LP gauge during venting.

Test Parameters – the whistle should sound between 5.0bar and 4.0bar.

●Should the whistle not sound at the preset pressure, refer to Dräger

Service.

Note: If the selected independent air supply incorporates a high

pressure whistle then the HPWWU will sound first.

●Following venting of the whistle, disconnect the female coupling of the

hose from the independent air supply.

●Fold the rubber cover from the front of lung demand valve and press

centre of diaphragm to vent pressure. Refit the rubber cover.

6.6 Fitting LDV to face mask

●Inspect the face mask as defined in the relevant Instructions for Use.

●Fully extend (open) the straps of the head harness.

Type A

●Check that the face mask port and the connector O-ring of the LDV are

clean and undamaged.

●Push the connector of the LDV into the port of the face mask until it

‘clicks’ in position.

●Check that the attachment is secure by pulling the LDV away from the

face mask – there should be no axial movement.

Types AE and N

●Check that the face mask port and sealing ring are clean and

undamaged.

●Screw the hand wheel of the LDV into the port of the face mask and

align the LDV as shown in Fig. 1 then finally tighten.

●Having ‘passed’ the test, and the LDV fitted to the face mask, the

equipment is now available for use.

7 Use

Safety Warning: Before using the airline manifold connection to the

equipment, ‘check’ that the independent air supply to be used

complies with air quality, pressure and flow requirements (see

Technical Data) and that a ‘Permit for Use’ has been issued. The

respirable breathable air supply source connection to the wearer

must be located in, or positioned in a safe and uncontaminated area.

Dräger recommend that a ‘Controller’ must be present at all times at

the air source connection to monitor and maintain the air supply to

the wearer of the Dräger PAS Colt Series Airline equipment.

7.1 Putting on equipment

●Check content indicator of the cylinder assembly ensuring a fully

pressurised cylinder, i.e. contents indicator needle must be aligned

with the nominal charged pressure – 200 or 300bar.

●Type A and AE – Press the reset button of the LDV to switch ‘Off’

positive pressure.

●Extend the shoulder strap. Open the buckle of the waist belt and

extend the strap at the male buckle end of the strap. Leave the female

buckle in position.

●While supporting the face mask, place the left arm through the

shoulder harness, taking the harness over the head and onto the right

shoulder, positioning the strap diagonally across the body with the

cylinder/carrying Holster positioned against the left hip. Loop the waist

belt around the waist and fasten the buckle – Do Not tighten. Put the

neck strap of the face mask over the neck then insert the neck strap

stud into the hole in the centre strap of the head harness. Face mask

is now in the ready position.

●Grip the cylinder valve with the left hand and lift until the waist belt is in

line with the waist then pull the free end of the waist belt strap, through

the male buckle, until the equipment is secure and comfortable on the

waist. Pull down and adjust the shoulder strap.

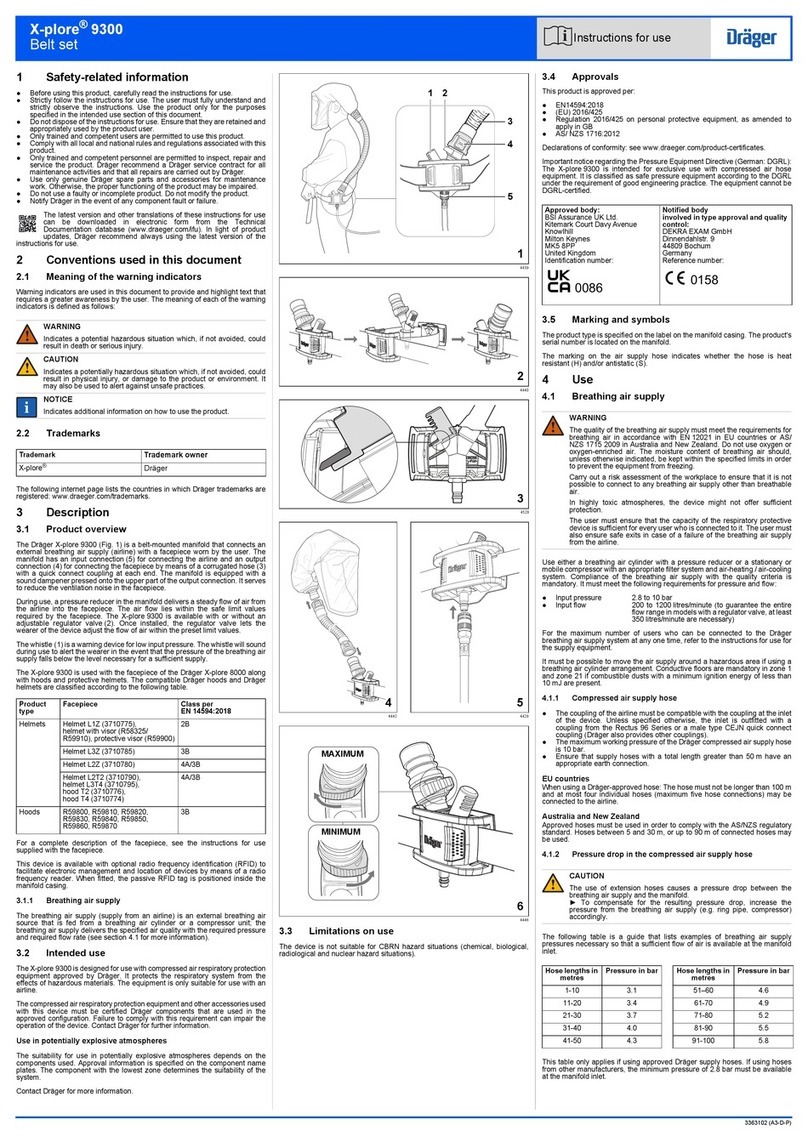

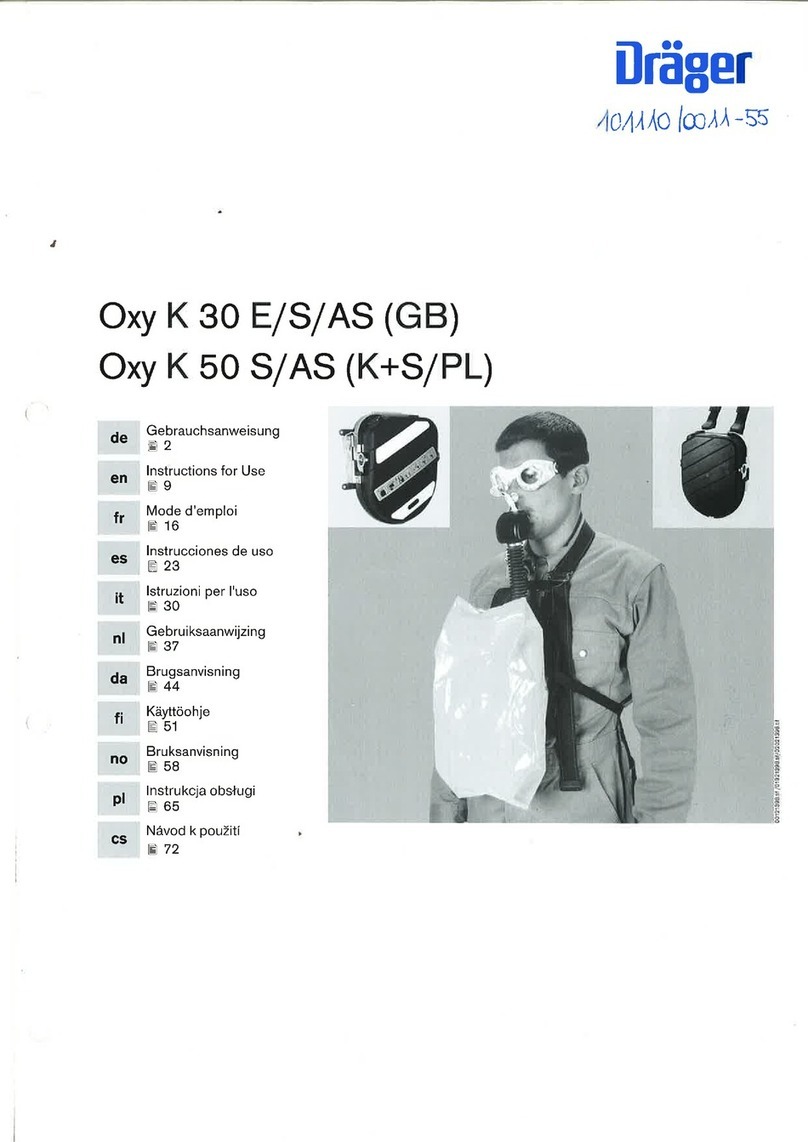

Figure 2 shows the correct wearing position.

●Type A and AE – Press the reset button of the LDV to switch ‘Off’

positive pressure.

8 Pre Operational Checks

The Controller

●‘Close’ any relief valves that may be fitted to the independent air supply

and then slowly, but fully, ‘Open’ the valve of the independent air

supply to pressurise the system.

The Wearer

●Type A and AE – Press the reset button of the LDV to switch ‘Off’

positive pressure mechanism.

●Connect the male coupling (1) Fig. 2 to the female QRC of the supply

hose of the independent air supply.

Safety Warning: Facial hair, beard stubble, side-whiskers, and the

wearing of spectacles will adversely affect and interfere with face

mask seal. Correct fit of face mask only ensured if face mask seal

makes close contact with skin.

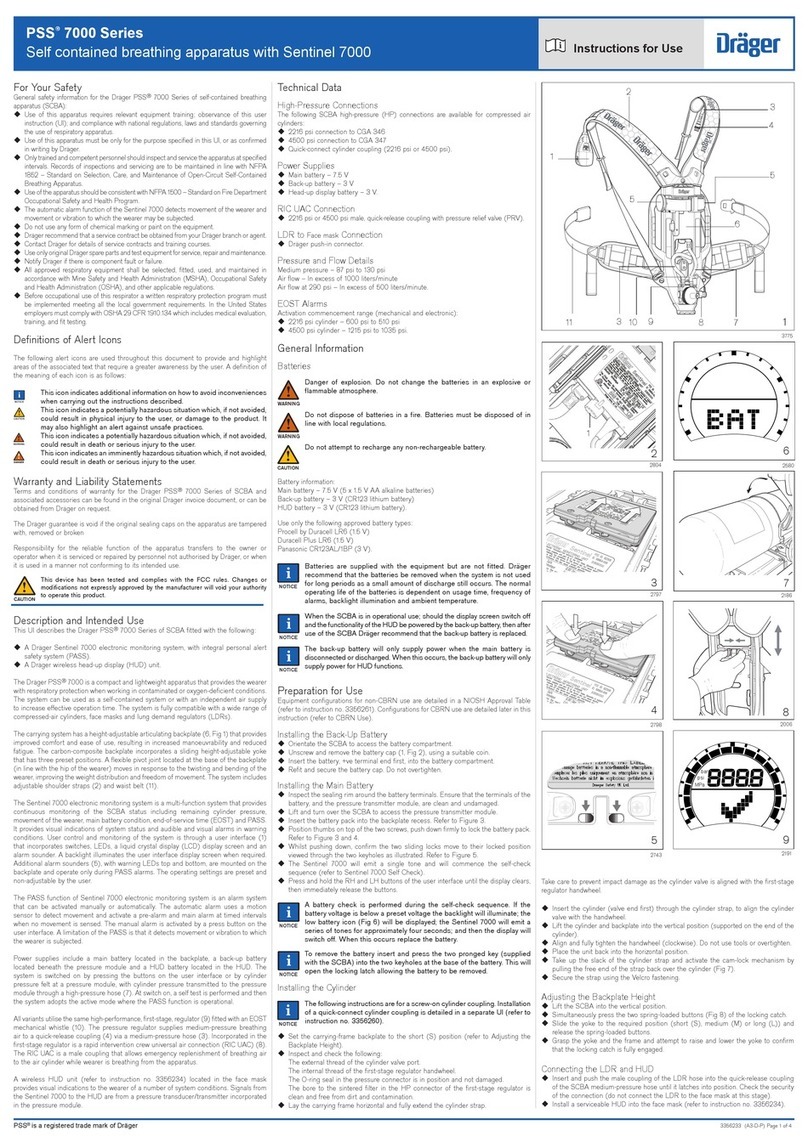

●Spread the head harness (Fig. 3). Drop the head forward and place

chin into the chin cup of the face mask, position harness over the head

locating harness centre plate with back of the head.

●Refer to Fig. 4. Tighten both lower (1), then upper straps (2) evenly

towards back of the head. Check and if necessary, tighten the centre

strap (3).

●On achieving a face seal and on taking first breath inhalation the Type

P and PE LDV’s will automatically switch to positive pressure starting

the air supply to the face mask.

●Check that the head has a full range of movement without pulling

against the LDV hose. If any resistance to movement is felt, re-adjust

the hose routing and then recheck. If resistance is still felt, Do Not use

the breathing apparatus and contact Dräger.

●Breathe normally, and before use perform Function Check.

8.1 Function Check

The Controller

●‘Close’ the valve of the independent air supply.

The Wearer

●Breathe normally to vent air from the system. During venting the

whistle (if fitted) will alarm at the preset pressure. When fully vented,

hold breath. The face mask should hold onto the face indicating a

positive seal.

●Immediately indicate to the ‘Controller’ of a positive face seal and

request to immediately ‘open’ the valve of the independent air supply.

The Controller

●When ‘Wearer’ indicates to the ‘Controller’ of a positive face seal – the

‘Controller’ should immediately ‘Open’ the valve of the independent air

supply to pressurise system.

The Wearer – In Use

●Inhale and hold breath. Unit must balance, i.e. no audible leak.

●Continue breathing normally. The expired air should flow easily out of

the exhalation valve.

●Continue breathing normally and proceed to the working area.

The Wearer – Evacuation

●Breathe normally.

●When the task is completed, or when advised by the ‘Controller’ –

proceed to the safe area (Controller). During evacuation take care to

hold and carefully withdraw the airline supply hose. See After Use.

IN AN EMERGENCY

●‘Open’ the cylinder valve of the equipment (anticlockwise) slowly, but

fully. Breathe normally.

●Disconnect the male coupling (1) Fig. 2 from the female QRC of the

hose from the independent air supply. Breathe normally and

immediately leave the hazardous area by the shortest and safest

escape route.

Safety Warning: When in an escape scenario Dräger strongly advise

that the supplementary supply facility is not used.

9 After Use

Safety Warning: Do Not remove equipment until in safe area, clear of

hazard.

Airline Mode – The Wearer

●Release the side straps of the head harness.

●Type A and AE – Press the reset button of the LDV to switch ‘Off’

positive pressure then remove the face mask.

Airline Mode – The Controller

●Following removal of the face mask by the wearer, ‘Close’ the valve of

the independent air supply.

Airline Mode – The Wearer

●Firmly press the centre of the rubber cover of the LDV to activate the

airflow from the LDV to vent pressure from the system.

Safety Warning: Do Not direct the airflow onto the face, eyes or skin.

●Following venting, disconnect the male coupling (1) Fig. 2 from the

female QRC of the hose from the independent air supply.

Airline Mode – The Controller

●Refer to the After Use section of the Instructions for Use relevant to the

independent air supply

9.1 Escape Mode

●Release the side straps of the head harness.

●Remove the face mask then ‘Close’ the cylinder valve.

●Type A and AE – The system will vent from the lung demand valve.

Type N – Fold rubber cover from the front of lung demand valve and

press centre of diaphragm to vent pressure. Refit rubber cover.

9.2 Airline Mode and Escape Mode

●Following venting of the equipment, unbuckle the waist belt, lift the

shoulder strap buckle to loosen the harness then remove the

equipment.

Note: Do Not drop or throw down equipment as damage could occur.

●Type A and AE – Press the reset button of the LDV to switch ‘Off’

positive pressure.

●Pass equipment to Service Department.

10 Routine Maintenance

To be performed after use of equipment.

See also Maintenance and Test Intervals Chart.

10.1 Removal of Cylinder

Safety Warning: Cylinder valve should be closed and system vented.

●Unscrew the hand wheel of the reducer from the cylinder valve and

carefully remove the valved cylinder assembly from the carrying

Holster. To prevent damage, ensure that the hand wheel of the

pressure reducer remains clear of the cylinder.

●Recharge the cylinder.

10.2 Charging Cylinders

Refer to ‘For Your Safety’

Safety Warning: Air quality for compressed air breathing systems

must conform to the requirements of EN12021.

Only charge compressed air cylinders which:

●Conform to National Standards.

●Feature the original manufacturers test date and test mark.

●Have not exceeded the test date indicated on the cylinder by the last

testing station.

●Do Not used damaged cylinders.

Recharge to the rated pressure indicated on the label or stamped on the

neck or shoulder of cylinder. Dräger recommend a charge rate of 27bar/

minute. Rapid charging will induce an increase in temperature resulting in

an incomplete charge – check pressure at ambient and if required ‘Top Up’

charge.

To prevent overcharging of the selected cylinder Dräger recommend that

a pressure-limiting device is fitted to the charging compressor.

10.3 Visual Inspection

Check the integrity of,

●Bandolier Shoulder Harness with Waist belt.

●Cylinder Carrying Holster – Fixed.

●Pressure Reducer, LDV and Hose Assemblies.

●Airline Manifold Connection and Hose – with or without LP whistle.

●Face mask – refer to relevant Instructions for Use.

●Valved Cylinder Assembly with Contents Indicator.

●Damaged cylinders must not be used.

●Optional Variants

●Pressure Reducer with ChargAir – Direct Filling Assembly.

●Cylinder Carrying Holster – Drop Down. Check function of the latching

mechanism.

11 Cleaning, Disinfecting, Drying

Safety note: Do not exceed 60 °C for drying, and remove components

from the drying facility immediately when dry. Drying time in a heated

dryer must not exceed 30 minutes.

Safety note: Do not immerse pneumatic or electronic components in

cleaning solutions or water.

Safety note: If water is trapped and then freezes inside the pneumatic

system of the breathing apparatus (such as the lung demand valve),

operation will be impaired. Prevent any liquid from entering, and

thoroughly dry the breathing apparatus after cleaning to prevent this

from occurring.

For information about suitable cleaning and disinfecting agents

and their specifications refer to document 9100081 on

www.draeger.com/IFU.

Refer also to the Instructions for Use for the lung demand valve, face mask

and other associated equipment.

●Use only clean lint-free cloths

●Clean the breathing apparatus manually using a cloth moistened with

cleaning solution to remove excess dirt.

●Apply disinfecting solution to all internal and external surfaces.

●Rinse all components thoroughly with clean water to remove all

cleaning and disinfecting agents.

●Dry all components using a dry cloth, in a heated dryer or in air.

●Contact service personnel or Dräger if disassembly of pneumatic or

electronic components is required.

12 Lung Demand Valve (LDV)

12.1 Internal cleaning and disinfecting

Safety note: Internal cleaning and disinfecting may only be carried

out by properly trained personnel. Disassembly of the lung demand

valve by untrained personnel is not permitted and may damage the

equipment.

Safety note: Ultrasonic cleaning will damage the diaphragm. Dräger

recommend that ultrasonic cleaning methods are not used for any

part of the lung demand valve.

Safety note: Cleaning solutions will eventually remove lubricants

from moving parts. Carry out functional tests following cleaning,

disinfecting and drying. Re-lubricate moving parts as required.

●Roll back the rubber sleeve (Fig. 5, Item 1) to access the retention

staple (2). Insert a flat blade screwdriver under the staple and while

pressing the end of the hose into the hose connection of the reducer –

remove the retention staple. Remove hose from the reducer.

●Remove component parts of the relief valve, i.e. the spring, O-ring

retainer and O-ring from the nozzle of the medium pressure hose. If

required, remove the lung demand valve from the front port of the face

mask.

●Disassemble the lung demand valve as follows:

○Remove the rubber cover (Fig 6, Item 1) from the front of the lung

demand valve housing. Twist the bayonet cap (2) anticlockwise to

remove it (a plate spanner is available from Dräger for this task –

see Section 17). Do not attempt to remove the spring from the

bayonet cap, and do not stretch, compress or damage the spring

during cleaning and disinfecting (note that the spring is not fitted

on N-type lung demand valves).

○Carefully grip the slip ring (Fig 6, Item 3). If required, rotate the slip

until the external lugs are free from the retaining lugs of the

housing (Fig 7). Remove the slip ring from the housing.

○Carefully grip the centre of the diaphragm (Fig 6, Item 4) between

the thumb and forefinger. Tilt and remove the diaphragm from the

housing.

○Replace the rubber cover on the front of the lung demand valve to

protect the balanced piston lever (6).

●Immerse and manually agitate the lung demand valve, diaphragm, slip

ring and bayonet cap in a cleaning solution.

●Rinse all parts in clean water.

●Immerse and manually agitate all parts in a recommended disinfecting

solution.

●Remove the rubber cover from the front of the lung demand valve and

rinse all parts in clean water, taking care not to damage the balanced

piston lever.

●Press the reset button (5) to switch off the lung demand valve and then

connect the demand valve hose to a medium-pressure breathing air

supply (minimum of 4 bar).

Safety Warning: Do not direct the airflow on to the face, eyes or skin.

●Lightly press the balanced piston lever to blow away any moisture.

●Disconnect the air supply and dry all parts using a clean lint-free cloth

or a dedicated drying facility.

●If re-lubrication of the moving parts is required, position the main

lever (Fig 8, Item 1) and secondary lever (2) as shown. Apply two short

squirts of lubricant (Silkospray silicone lubricant) to the circled area in

the direction indicated by the arrow.

●Reassemble the lung demand valve as follows:

○Carefully install the diaphragm into the lung demand valve

housing.

○Carefully insert the profiled side of the slip ring into the housing,

ensuring that it sits inside the exterior bead of the diaphragm.