9928 Respirator

Fitting Instructions Warnings:

•As with the use of any respiratory device, the wearer must

first be trained in the proper use of the product.

•This product does not protect the wearer against gases

vapours, solvents from paint spray operations or atmospheres

containing less than 19.5% oxygen.

• 3M suggests the 9928 respirator for use up to 10 times the

Occupational Exposure Limit (OEL) of Ozone, and relief from

nuisance levels of organic vapours (i.e. levels below the OEL).

• Use only in adequately ventilated areas containing sufficient

oxygen to support life.

• Do not use when concentrations of contaminants are

immediately dangerous to life or health.

• Leave the area immediately if:

* breathing becomes difficult

* dizziness or other distress occurs

• Discard and replace respirator if it becomes damaged,

breathing resistance becomes excessive, or at the end of one

shift.

• Never alter or modify this device.

Respiratory protection is only effective if it is correctly

selected, fitted and worn throughout the time when the wearer

is exposed to hazards.

3M offers advice on the selection of products and training in

the correct fitting and usage.

For more information on 3M products and services please call

the 3M Health & Safety Helpline on 0870 60 800 60.

For callers within the Republic of Ireland: 1 800 320 500.

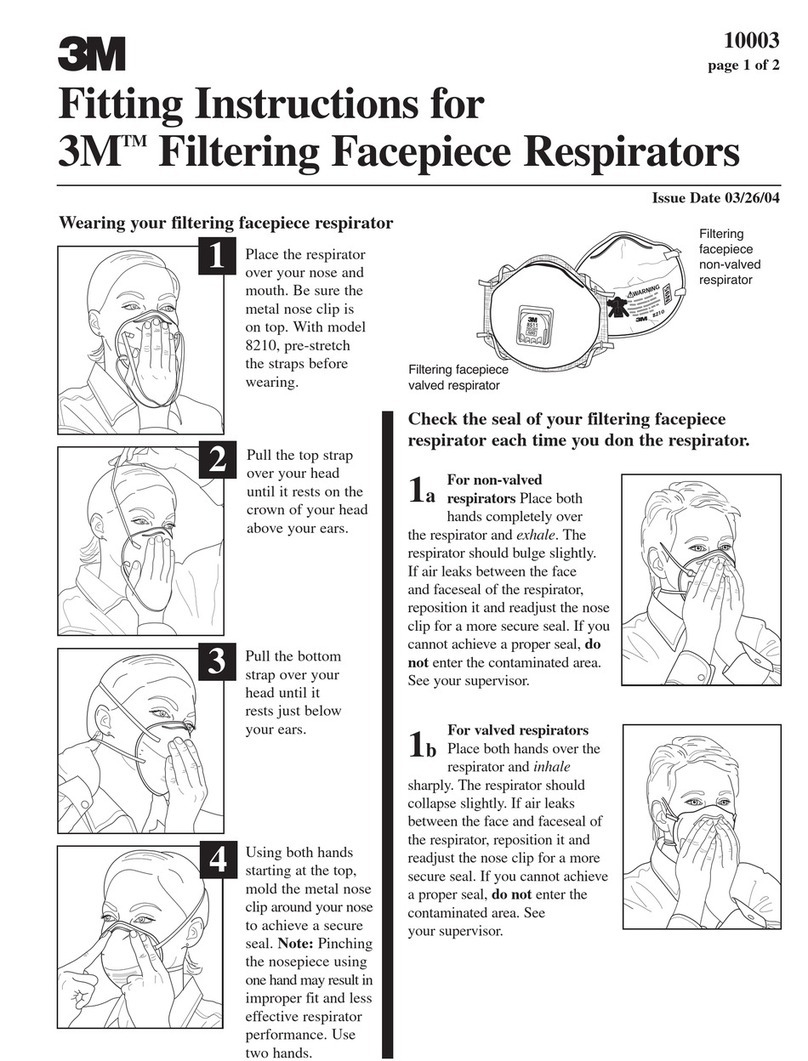

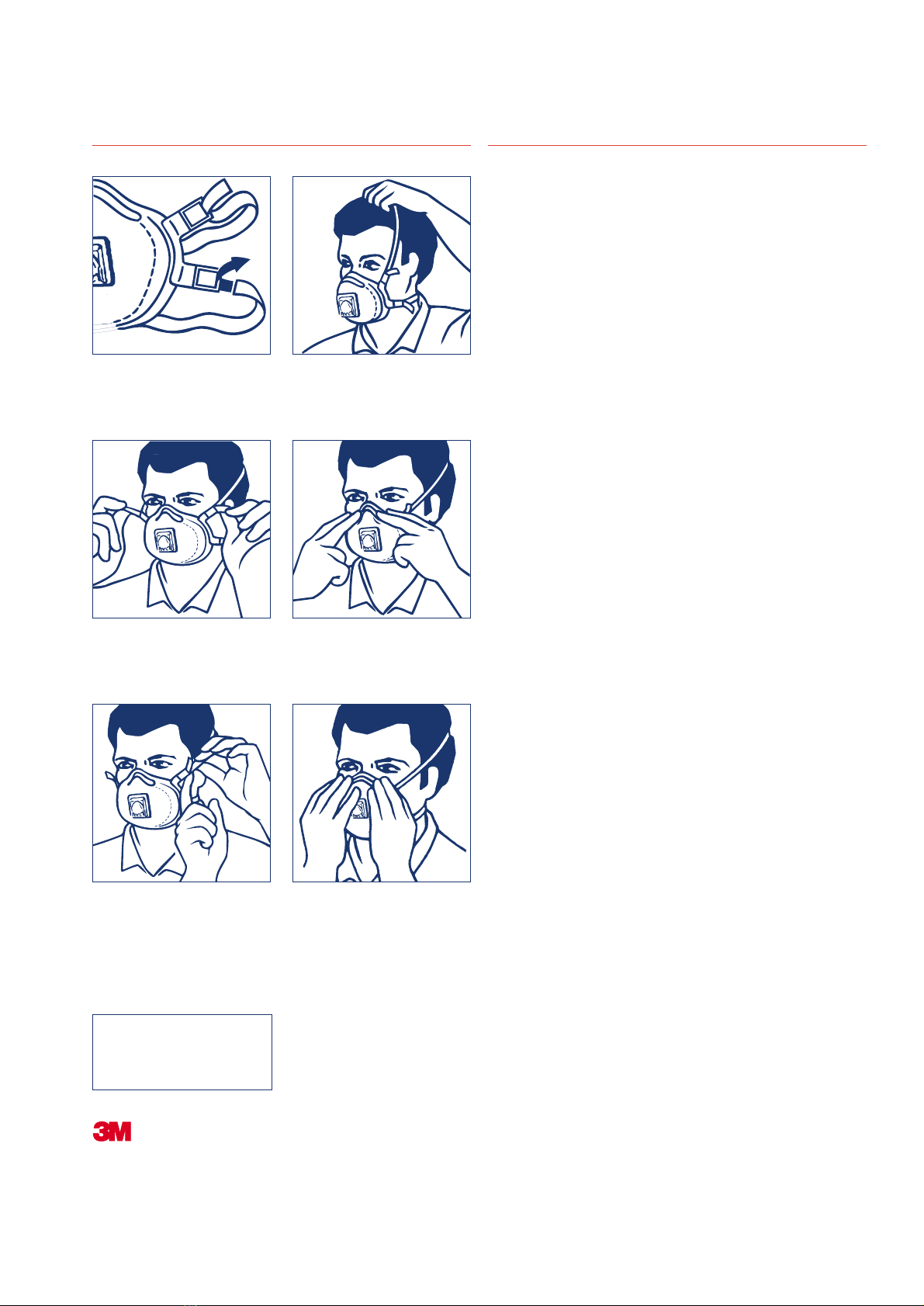

1.Thread top elastic strap through

top buckles. Repeat for bottom strap

and buckles. Place the bottom elastic

strap around the head just below the

ears. Untwist the strap.

2. Place the top elastic strap around

the head, above the ears. Untwist the

strap.

3.Adjust tension by pulling tabs of

each strap, as shown. 4. Using both hands, mould metal

nosepiece comfortably to shape of

nose.

Occupational Health Group

3M United Kingdom PLC 3M Ireland

3M House, PO Box 1, 3M House, Adelphi Centre, Upper Georges St.

Market Place, Bracknell, Dun Laoghaire

Berkshire RG12 1JU Co. Dublin, Ireland

Tel: Bracknell (01344) 858000. Tel: 01 2803555

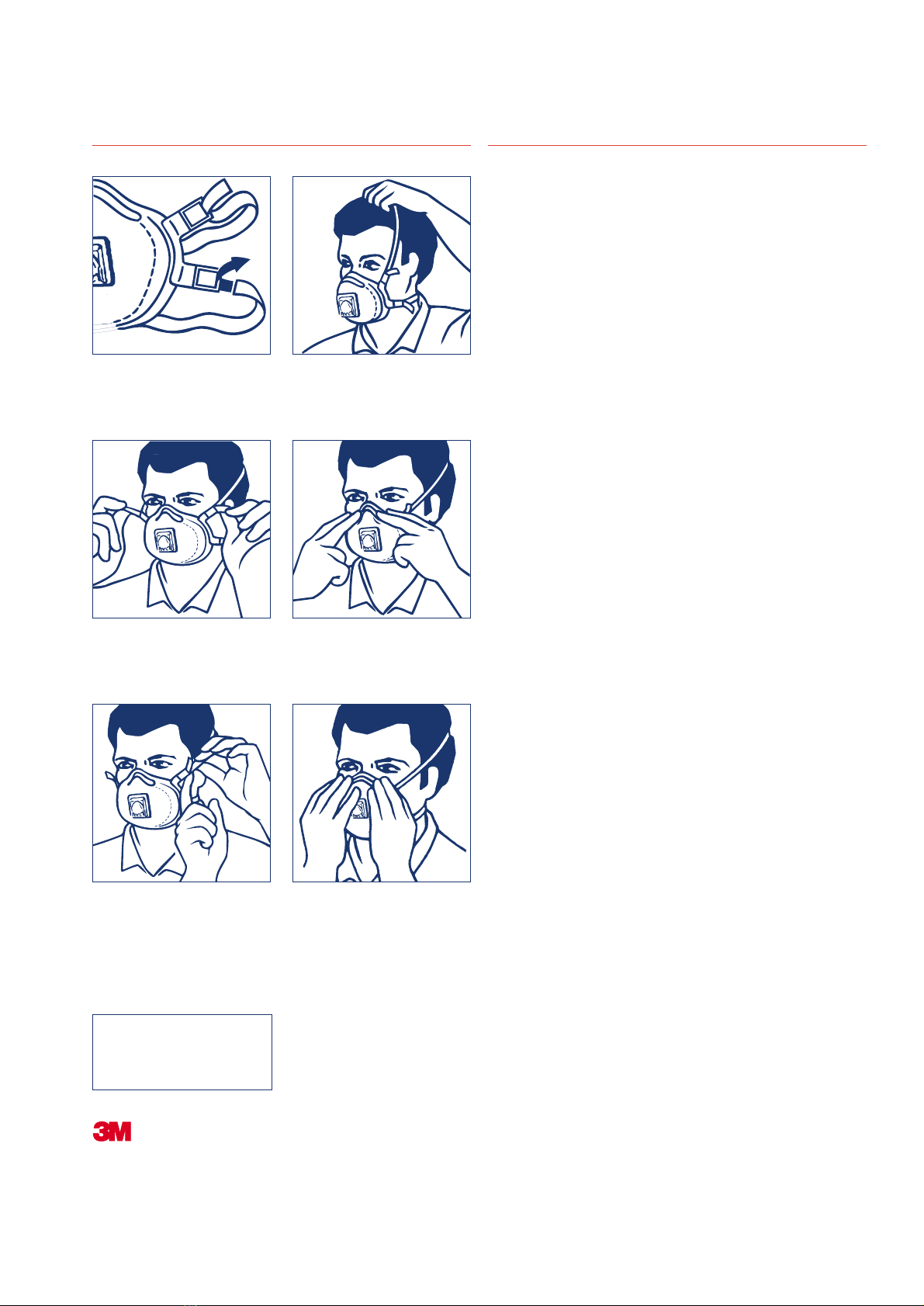

5. Strap tension may be decreased

without removing respirator from the

head by pushing out on the back of

the buckles. If you cannot achieve a

proper fit do not enter contaminated

area. See your supervisor.

Note: do not use with beards or

other facial hair that may inhibit

contact between the face and the

edge of the respirator.

6.The seal of respirator on the face

should be fit-checked prior to

wearing in the work area.

a) Cover the front of the respirator

with both hands, being careful not to

disturb the position of respirator.

b) Inhale sharply. A negative

pressure should be felt inside

respirator. If any leakage is detected,

adjust position of respirator and/or

tension of strap. Retest the seal.

Repeat the procedure until the

respirator is sealed properly.

CH9928