Description

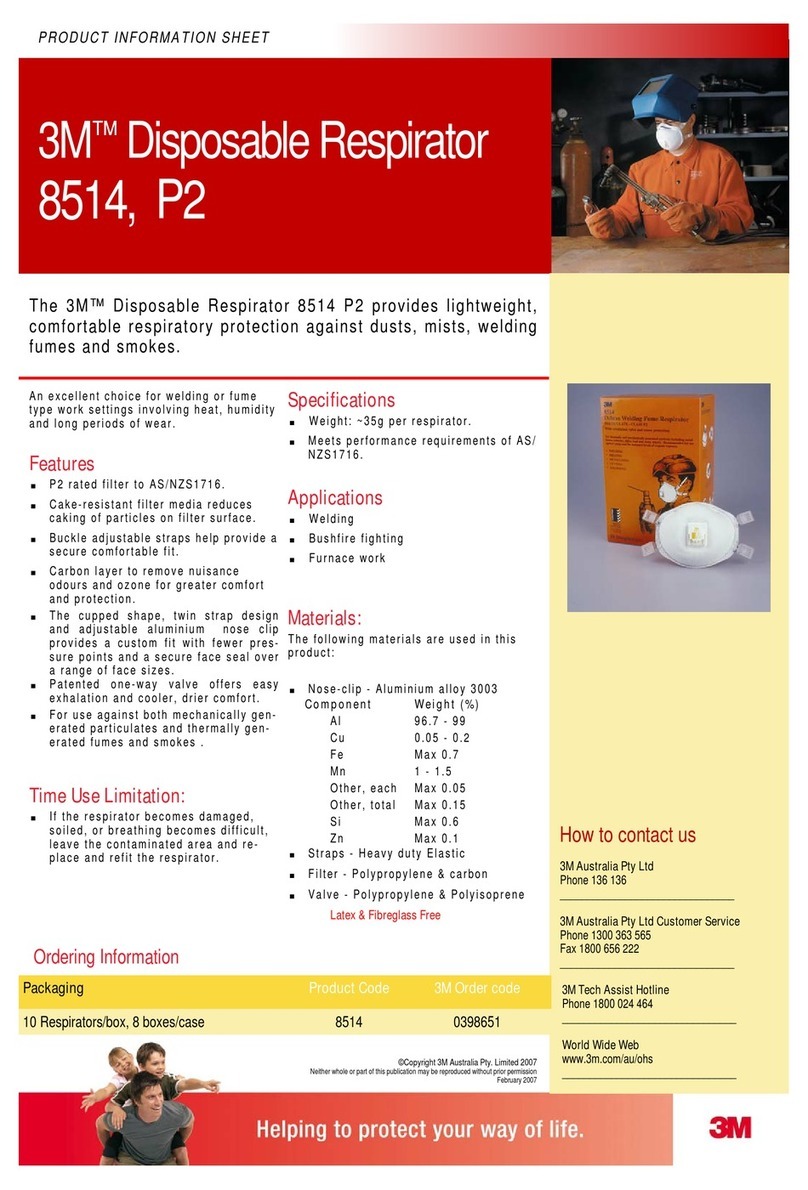

The 3M™ 8710, 8210, 8812 and 8822 Particulate Respirators

provide eective respiratory protection for use in industries

where workers will be exposed to dust particles and/or non-

volatile liquid particles.

Tested and certified to AS/NZS 1716:2003.•

Traditional convex shape, with nose clip and twin strap design.•

Durable, collapse resistant inner shell.•

R e l i a b l e , e ective protection against fine particles.•

3M™ Advanced Electret Filter Material gives eective filtration•

with low breathing resistance for consistent high quality

performance.

3M™ Cool Flow™ exhalation valve oers improved comfort in•

hot humid environments and/or where work is hard and physical*.

Materials

The following materials are used in the production of the 8710,

8210, 8812 and 8822 Particulate Respirators:

Straps• 8812, 8822 – Polyisoprene

8710 and 8210 – Thermoplastic Elastomer

Staples• 8812, 8822 – Steel

8710 and 8210 – no staples

Nose Foam• Polyester

Nose Clip• 8210 – Aluminium

8710, 8812, 8822 – Steel

Filter• Polyester / Polypropylene

Valve*• Polypropylene

Valve diaphragm*• Polyisoprene

These products do not contain components made from natural

rubber latex.

Maximum mass of products:

• Unvalved (8710 & 8210) = 8g

• Valved (8812 & 8822) = 13g

Standards

These products meet the requirements of Australian New Zealand

Standard AS/NZS 1716:2003, Respiratory protective devices. They

should be used to protect the wearer from solid and non-volatile

liquid particles only.

Particulate Filter Respirators are classified by filtering eciency and

maximum total inward leakage performance (P1 & P2), also by

inhalation resistance.

P1 filters are indended for use against mechanically generated

particulates such as those generated from sanding, grinding, drilling,

sweeping etc.

P2 filters are intended for use against both mechanically and

thermally generated particulates e.g. welding, brazing etc. P2 filters

may also help reduce breathing in pathogenic biological airborne

particulates such as influenza virus.

Approvals

These respirators have been produced to comply with the

requirements of the Australian / New Zealand Standard AS/NZS

1716:2003 under an agreed production certification scheme

operated during manufacture in accordance with the SAI Global

StandardsMark programme.

Applications

These respirators are suitable for use in concentrations of solid and

non-volatile liquid particles up to the following limits:

Model AS/NZS 1716

Classification

Exhalation

Valve

Protection Factor

x ES

8710 P1 Unvalved up to 10x

8812 P1 Valved up to 10x

8210 P2 Unvalved up to 10x

8822 P2 Valved up to 10x

ES = Exposure Standard

Respiratory protection is only eective if it is correctly selected, fitted and

worn throughout the time when the wearer is exposed to hazards.

3M™ 8710, 8210, 8812 and 8822

Particulate Respirators

* 8812 and 8822 models only

Technical

Datasheet

Ташев-Галвинг ООД

www.tashev-galving.com