E. Troubleshooting

Ensure that breaker is installed correctly and all

terminal connections are torqued per instructions.

If the breaker fails to close check:

1.

2.

3.

4.

5.

For overload and short circuit on the system.

Handle position - TRIPPED - reset by moving

handle fully to OFF position and then to the ON

position, see Figure 4.

Undervoltage trip is supplied with rated

voltage.

Shunt trip is de-energized and no trip signal

exists

Breaker trip unit settings are properly adjusted.

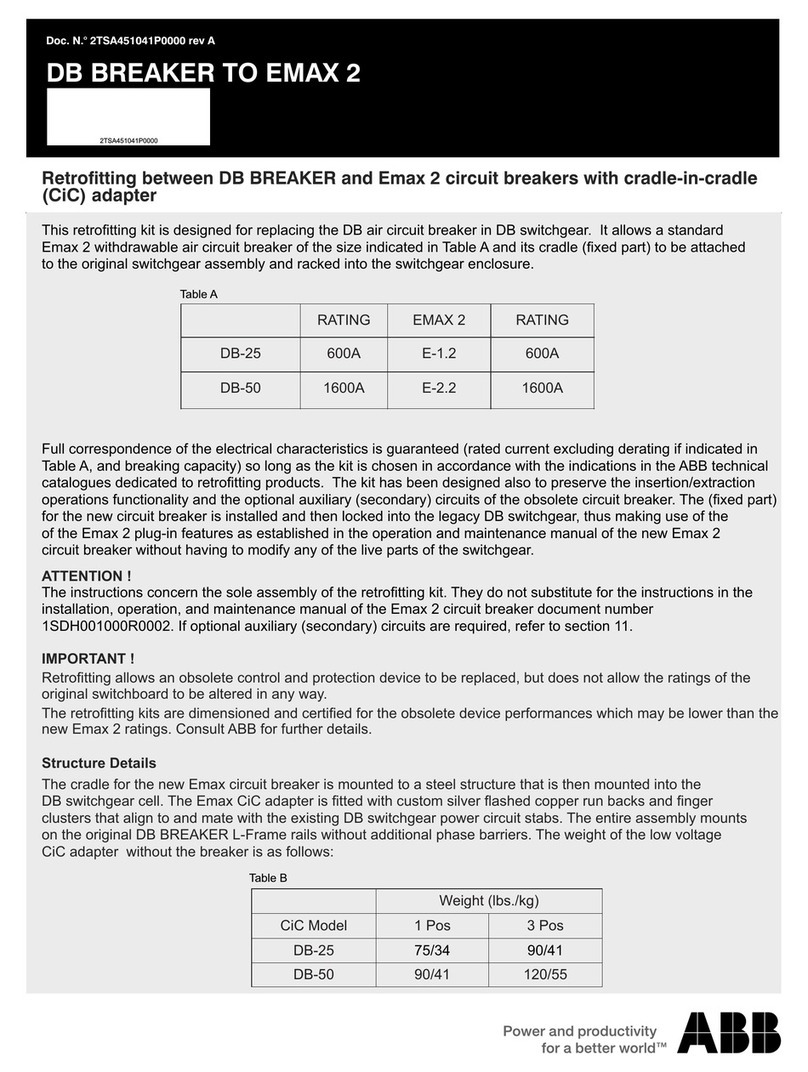

Installation instruction

references:DEH40324 –

Auxiliary switch & bell alarms.

DEH40363 – Undervoltage

release & shunt trip modules

DEH40532 – Terminal lugs.

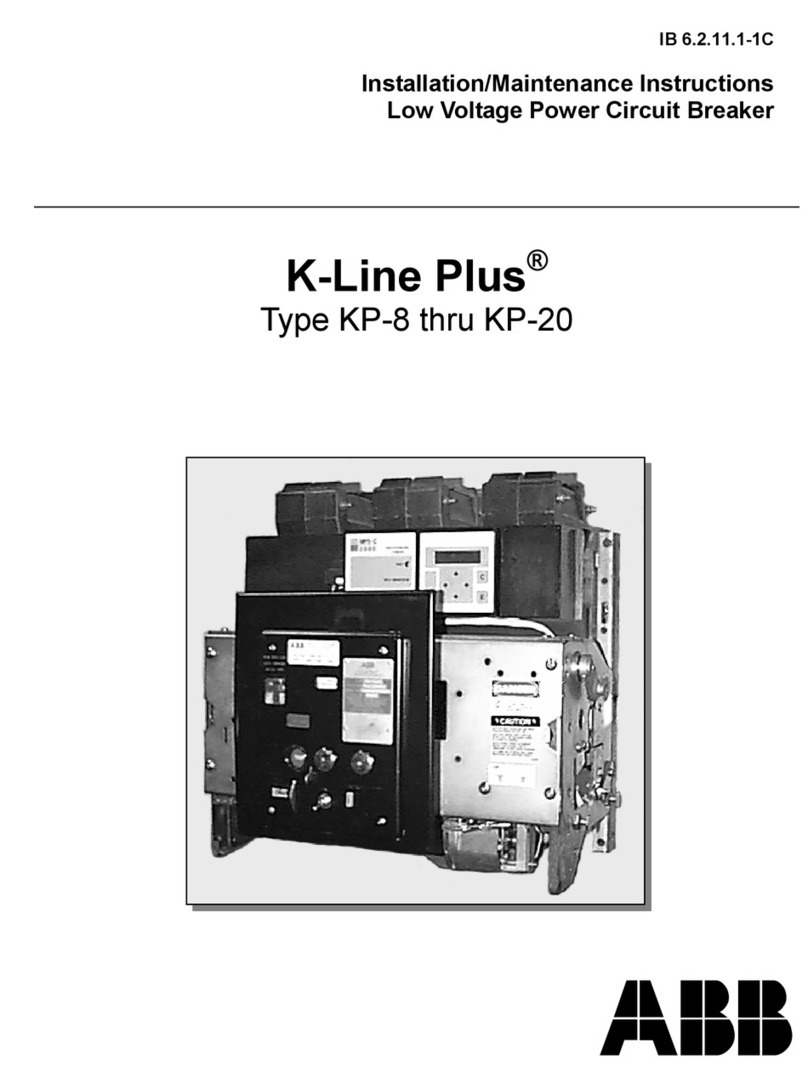

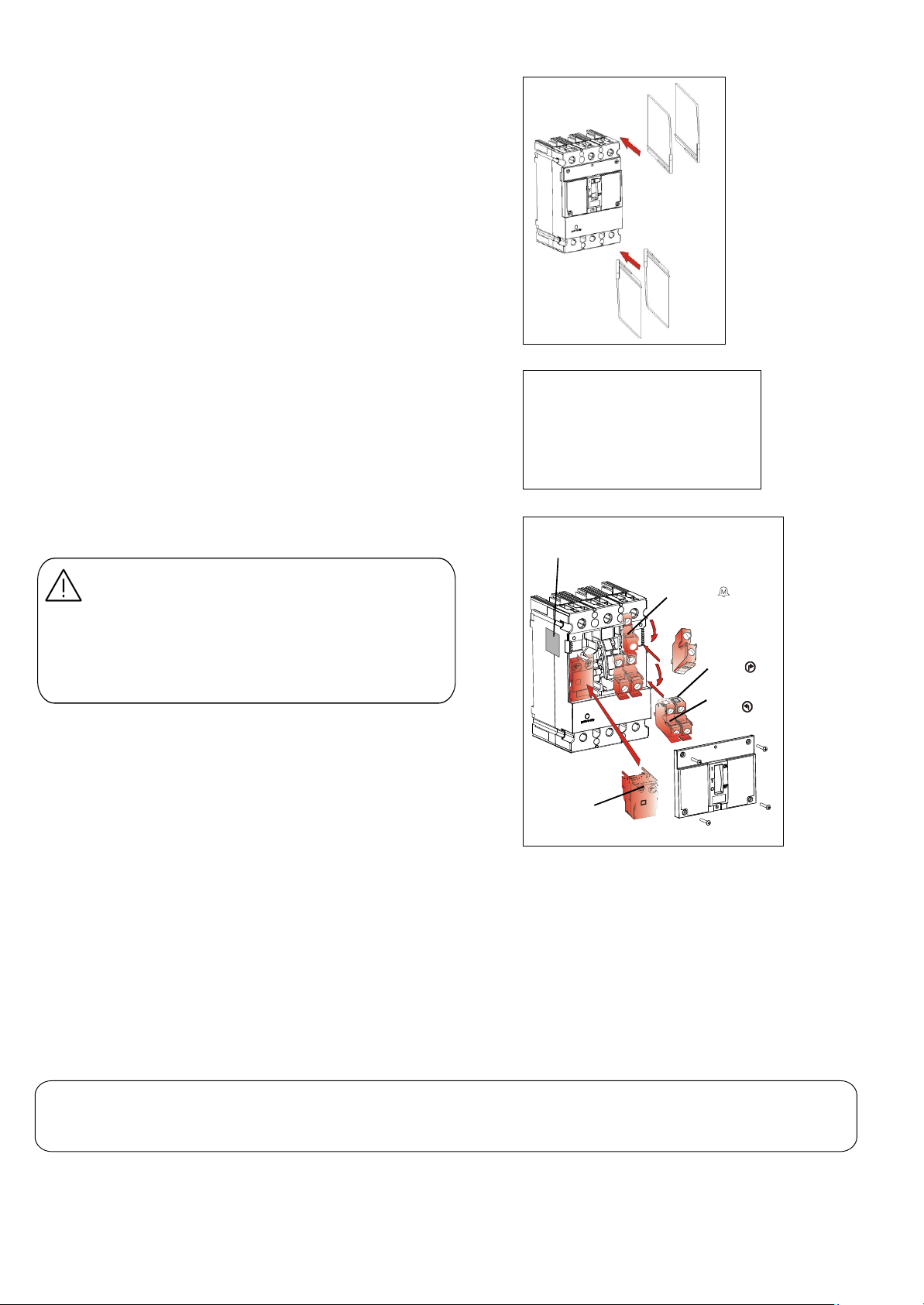

Optional inter-

phase Barriers

Applied accessorylabel to

side of breaker

Bell al arm swit ch ID

Outside auxiliary

switch ID

Inside auxili ary

switch ID

Shunt trip and

Unde rvoltage modu le

Warning: Danger of electrical shock or injury. Turn off

power supplies ahead of equipment before attempting

to service.

Important:: Danger d’electrocution. Couper

l’alimenation avant d’effectuer toute action d’entretien.

Operate the breaker push to test button and toggle the

handle several times, testing the mechanical operation

of the device. If there are any signs of damage or if the

mechanism is sluggish or sticky, replace the breaker.

For abnormal or heavy duty conditions refer to NEMA

publication AB4 and for recommended maintenance

practices NFPA70B.

G. Storage

Store in a dry, dust free, environment protected from

corrosion. Long term storage should be in the original

shipping carton. Temperature range –40°C to +80°C.

H. Accessories

For full details of the accessories and their application,

contact your local ABB representatives. When installing

accessories read the accompanying accessory

installation instruction and follow carefully all cautions

and warnings.

®

—

Fig 6. Typical Accessories. See Buylog for Details

4

1SQC930037M0201, DEH41073 February 2020

—

ABB Inc.

305 Gregson Drive

Cary, NC 27511.

electrification.us.abb.com

—

We reserve the right to make technical

changes or modify the contents of this

document without prior notice. With

regard to purchase orders, the agreed

particulars shall prevail. ABB Inc. does not

accept any responsibility whatsoever for

potential errors or possible lack of

information in this document.

We reserve all rights in this document and

in the subject matter and illustrations

contained therein. Any reproduction or

utilization of its contents – in whole or in

parts – is forbidden without prior written

consent of ABB Inc.

Copyright© 2019 ABB

All rights reserved

—

GE is a trademark of GE. Manufactured

by ABB Inc. under license from GE.

If technical assistance is required contact your

local ABB sales office. In the US call ABB Post

Sales Customer Service, 1-888-437-3765.

F. Maintenance

Generally no maintenance is required but it is

recommended that the breaker be cleaned and

inspected on an annual basis.

Note: For a 2 pole breaker there are no auxiliary

switch & bell alarm switch; For a 1 pole there are no

accessories; Installation of an accessory in a 2 pole

breaker is the same as a 3 pole breaker.

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be met

in connection with installation, operation, or maintenance. Should further information be desired or should particular problems arise that

are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the ABB Company. The breaker is a sealed unit,

which contains no user serviceable parts, tampering with seal will void warranty.