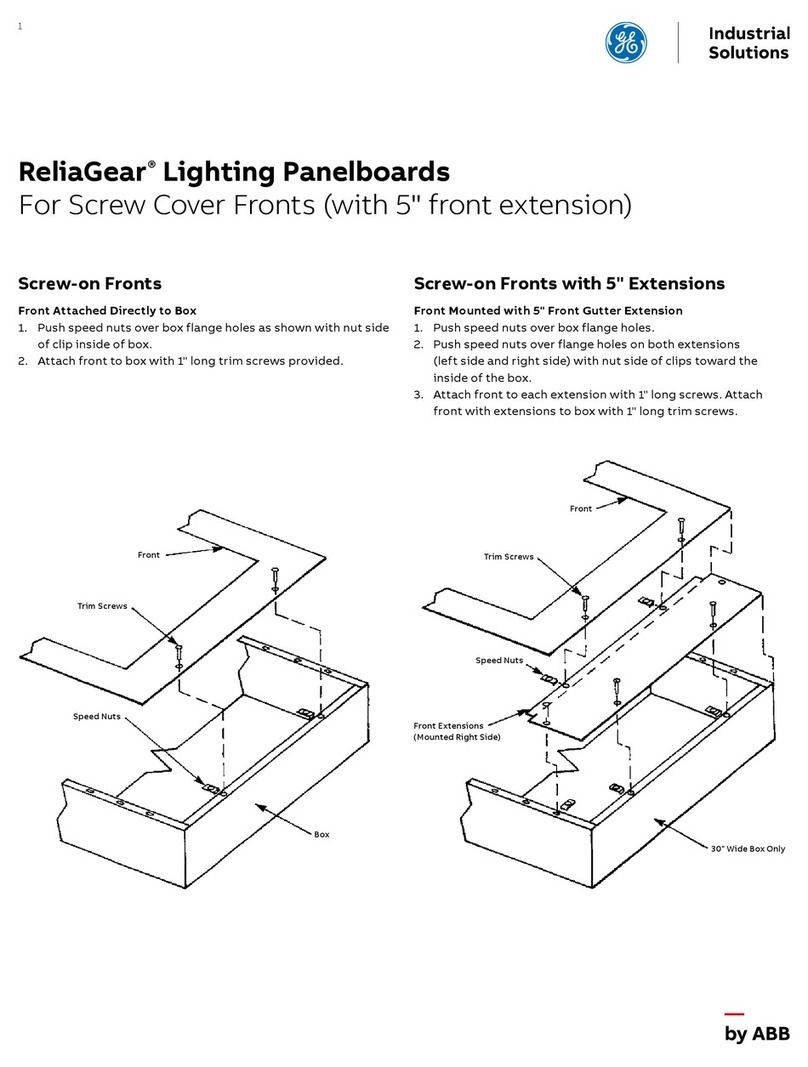

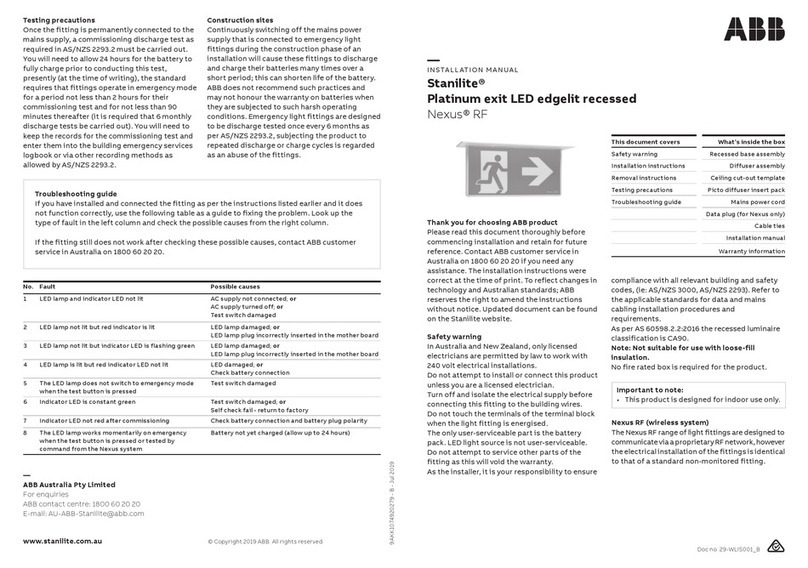

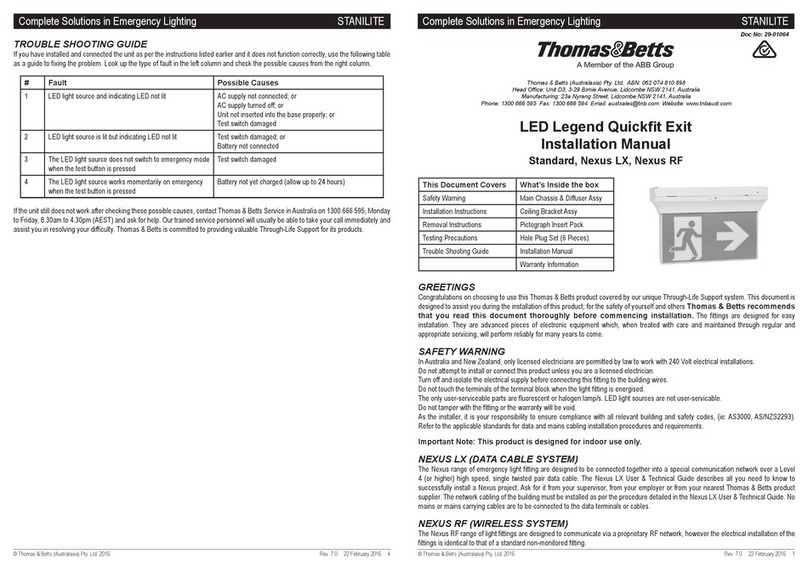

Enclosure

mounting

holes

354

164

Gear tray

mounting

screws

Figure 1 Figure 2

Figure 3

Installation instructions

Important: The mounting holes are at the same location as the lid’s screws, see figure 2. The holes

centre distance is 164 x 354mm. If the mounting holes are drilled through the enclosure, the

installer must seal the holes with suitable sealant to maintain the enclosure IP rating integrity.

1. Unscrew 4 screws and remove the lid.

2. Unscrew 4 screws from the gear tray then remove it from the enclosure.

3. Decide on the mains entry (back or side) then drill a cable entry hole to suit the conduit or cable

gland size. Remove all burrs and sharp edges around the cable entry hole and make sure the

enclosure is free of dust. For cable side entry; the holes centre is 25mm from the base.

Removal instructions

1. Before removing the installed fitting, de-

energise and lock of the supply circuit.

Note: There may be 2 actives present, ensure all

power is isolated before proceeding.

2. Remove the lid and gear tray from the

enclosure.

3. Disconnect the mains supply from the

terminal block (and data cable for Nexus LX

fitting or antenna cable for Nexus RF fitting)

and disconnect the battery plug from the PCA

before removing the fitting.

4. Determine the mounting location, hold the enclosure in position and secure it in place by

appropriate M6 screws (the housing mounting holes diameter is 6.4mm) (due to the wide variety

of building construction materials, fasteners are not supplied). Make sure the mounting screws are

fixed into solid material that is strong enough to support the weight of the fitting which is

approximately 4kg. A suitable washer should be used in conjunction with the screw.

5. Run cable in the ceiling or wall space as appropriate or surface mounted in conduit, slide the cable

gland over the cable then feed the cable through the entry hole of the enclosure. Allow adequate

wire length to reach the terminal block then secure the cable gland in place.

6. Terminate wires to the terminal block. Be careful with multi-stand conductors that all the strands

are twisted together before insertion into the terminal block. Any stray strands that inadvertently

come into contact with their neighbouring terminal will cause undesireable results when fitting is

powered.

7. Install the gear tray and secure it to the enclosure by 4 screws.

8. Check operation of the fitting to ensure that the installation was successful. When powered up.

allow a few minutes to give the battery a small charge then press the test button. Hold the test

button in for a few seconds and observe the operation of the lamp switching from mains to the

emergency mode. If the lamp on emergency mode works momentarily, that’s okay. Try again in a

few more minutes in case battery is completely discharged, it may take a little time to charge up

enough to operate even momentarily. After this time, press the test button again and if the lamp

does not work at all, check the supply, the connections and follow the instruction given in the

troubleshooting guide at the end of this document.

Wire colour

Orange +ive Red wire to LED strip

White -ive Black wire to LED strip

Earth Green/Yellow to terminal Earth or

Important: 24 hours is required to allow the fitting battery to reach full capacity, ie: prior to a

discharge test. As the installer, it is your responsibility to conduct the initial discharge testing of

the installed fitting. Refer to AS/NZS 2293.

Construction sites

Continuously switching off the mains power

supply that is connected to emergency light

fittings during the construction phase of an

installation will cause these fittings to discharge

and charge their batteries many times over a

short period; this can shorten life of the battery.

ABB does not recommend such practices and

may not honour the warranty on batteries when

they are subjected to such harsh operating

conditions. Emergency light fittings are designed

to be discharge tested once every 6 months as

per AS/NZS 2293.2, subjecting the product to

repeated discharge or charge cycles is regarded

as an abuse of the fittings.

Testing precautions

Once the fitting is permanently connected to the

mains supply, a commissioning discharge test as

required in AS/NZS 2293.2 must be carried out.

You will need to allow 24 hours for the battery to

fully charge prior to conducting this test,

presently (at the time of writing), the standard

requires that fittings operate in emergency mode

for a period not less than 2 hours for their

commissioning test and for not less than 90

minutes thereafter (it is required that 6 monthly

discharge tests be carried out). You will need to

keep the records for the commissioning test and

enter them into the building emergency services

logbook or via other recording methods as

allowed by AS/NZS 2293.2.