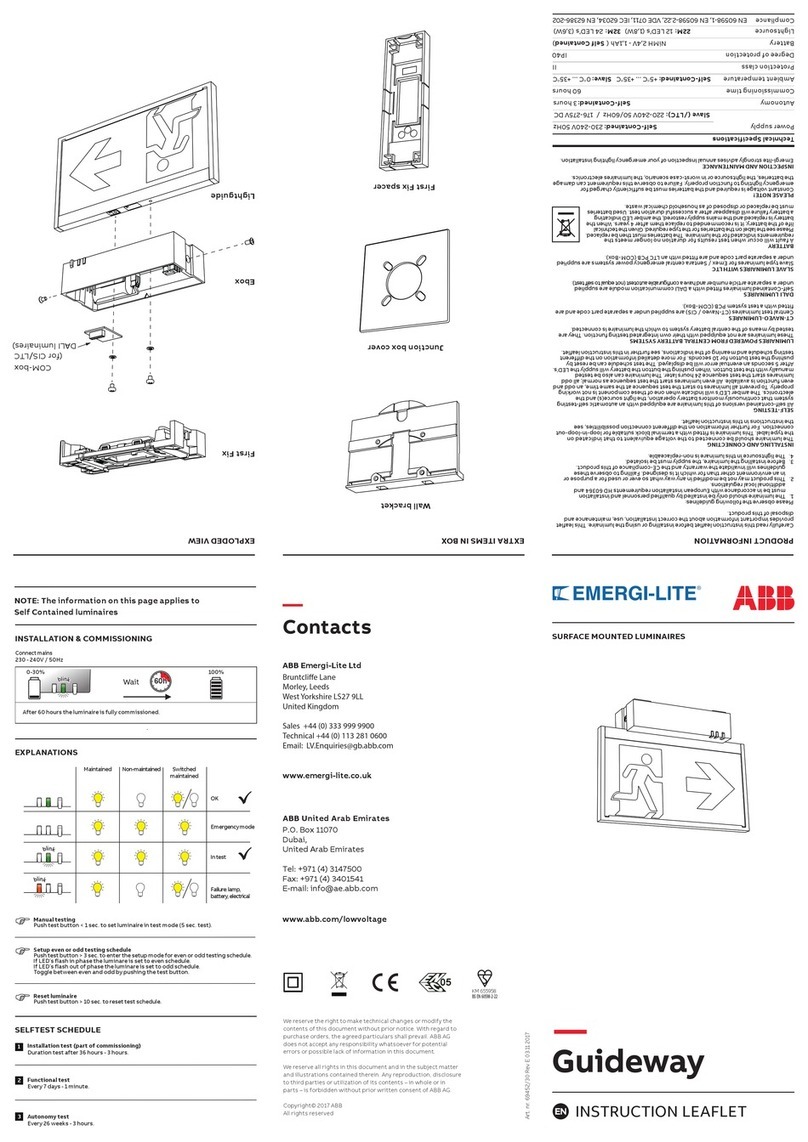

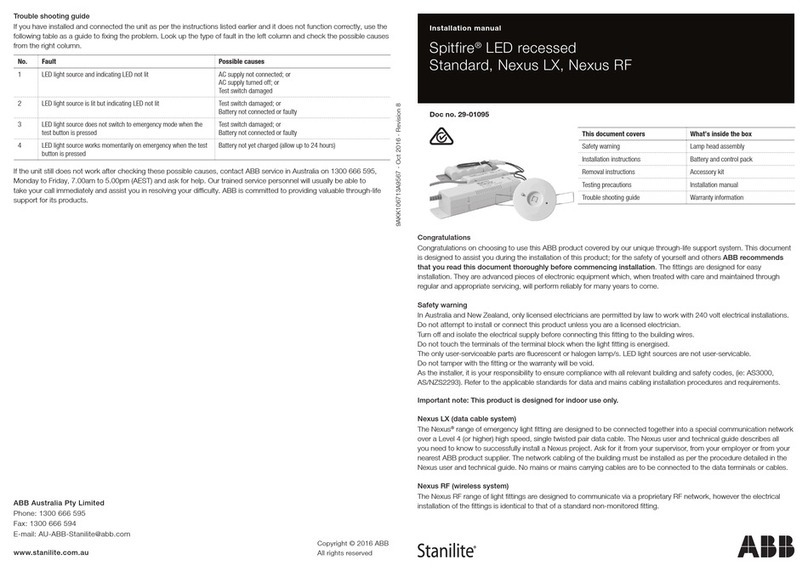

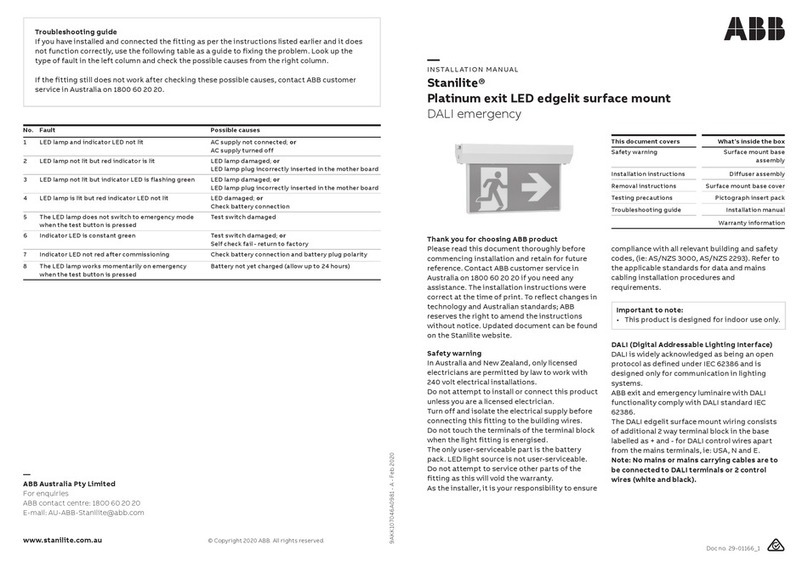

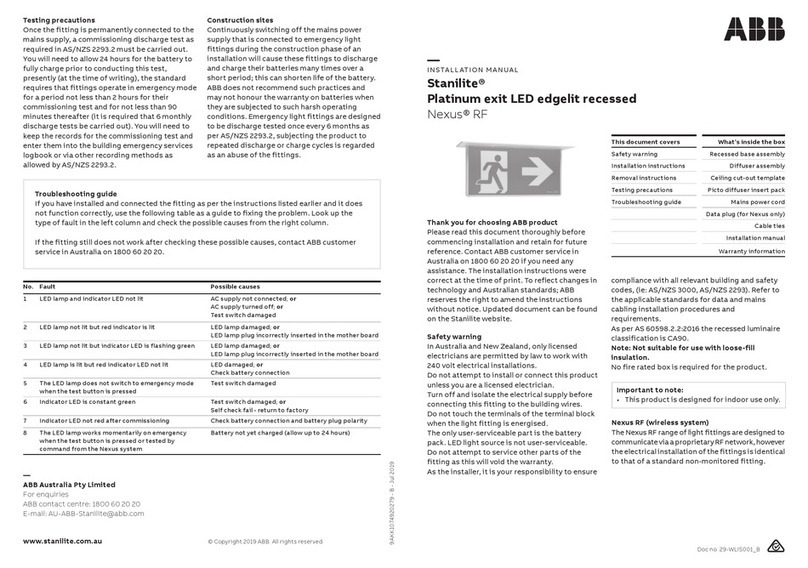

Installation instructions

Important note: A M6 torx screw driver or drive bit is required for the installation.

1. Remove the unit from the packing box and inspect it for damage or imperfections. If any damage is found, do not

install the unit, but replace it carefully into the packing box and notify the ABB product support hotline in Australia on

1800 222 435.

2. If all looks okay, installation can proceed.

3. Put the main frame upside down, remove six (6) special G6 x 1/2 counter sunk torx screws by using a torx pin driver

or screw driver. Gently insert a small flat head screwdriver into the side of the front cover to lever it out, remove the

front cover. See figure 3.

4. Loosen the thumb screws to remove the side diffusers. Leave the bottom diffuser on.

5. Remove the unit from the bracket by gently inserting a small screwdriver into the slot (at ‘D’ in figure 4) on the front of

the bracket towards the right hand end of the fitting to ease the locking tab into the fitting and away from the bracket.

The unit is then free to slide to the right along the bracket for about 50mm, at which time the slots line up and it can

be lowered away from the bracket, allowing the two to separate.

Note: The main metal frame can be mounted on either side but inside can only be accessed from one end. Make sure

to leave a gap of at least 650mm to remove the unit from the metal frame.

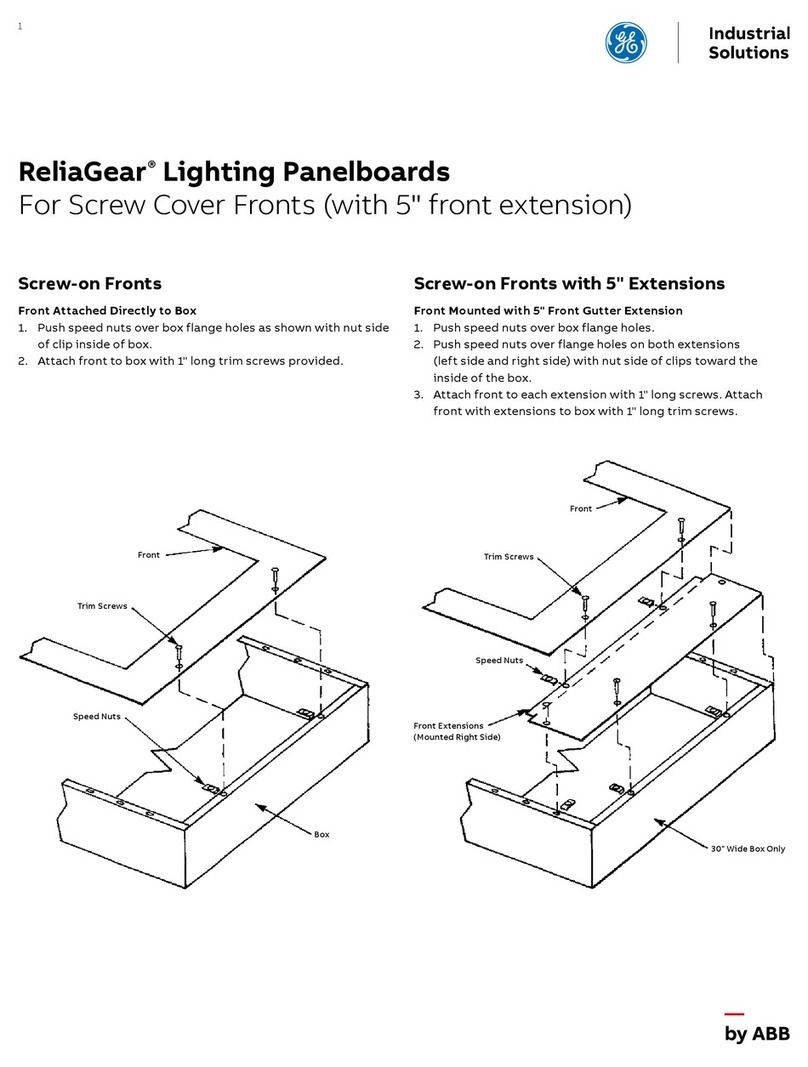

6. Determine the mounting configuration and position, ie: ceiling or wall. Drill mounting holes at the positions as shown

in figure 1 or figure 2. All drilling locations are indicated on the metal frame by dimple features. Due to the wide variety

of building construction materials, mounting screws are not provided with the unit. Use appropriate hardware to suit

the individual installation and structural support needs of the unit (17kg approx). The cable entry hole for wall mounting

can be drilled through the polycarbonate panel and the cable entry hole for ceiling mount must be drilled at the dimple

at the centre of the top face, marked A as shown in figure 1.

7. Run the cables in the ceiling or wall space as appropriate through the cable hole into the bracket, a suitable bush may

have to be used to protect the cable as it passes through the cable entry hole into the mounting bracket. Secure the

main frame to the wall or ceiling before terminating any wiring. Strip, connect and terminate the cables as indicated

in figure 3. Ensure that the double insulation of the cable/s passes completely into the terminal block enclosure so

that no single insulation is exposed when the cover is in place. Be careful with multi-strand conductors that all of the

strands are twisted together before insertion into the terminal. Any stray strands that inadvertently come into contact

with their neighbouring terminal or the metal frame of the fitting will cause undesirable results when the fitting is

powered. Install the plastic panel over the terminal block.

− Maintained fittings are design for permanent illumination: connect incoming unswitched active, neutral and earth to

terminal marked USA, N and E respectively.

− Data connection for Nexus LX product installation:

The same colour wire from each data cables connects to the terminal marked +.

The other colour wire from each of the data cables connects to the terminal marked -.

When connected, replace the terminal block cover so that it clicks and locks into place.

− No mains or mains carrying cables are to be connected to the data terminals or cables.

8. Fit the LED lamp (carefully follow the instruction label on top of the unit) and attach the unit to the mounting bracket

by aligning the top left hand end of the unit (the end without the protruding electrical connecting metal lugs) with the

large cut-away slot towards the left hand end of the bracket. Slip the left hand end of the unit up into the slot in the left

hand end of the bracket (step (1) in figure 4) and hold the unit horizontal to and parallel with the bracket. It should be

approximately 50mm to the right of its final destination. Simply slide the unit (step (2) in figure 4) 50mm to the left along

and into the bracket to engage the connection and the locking tab. Once in place, the unit cannot be removed from

the bracket without the use of a tool (a small screwdriver) to push in the locking tab at ‘D’ in figure 4.

9. Once powered up, the LED lamp should energise and remain lit until the power supply fails. The emergency function

of the light fitting should only operate when the normal lighting power supply fails or when somebody presses the

manual test button located on the side of the unit. Normal status of the unit when powered, red LED indicates that the

power is connected and the battery is charging or when commissioned on the Nexus LX/RF network and the unit is

receiving a command from the Nexus LX/RF controller to switch into emergency mode. Normal initial uncommissioned

status of the indicating LED on the unit is flashing green. Once commissioned, the LED changes to a steady red and

flashes red during test. Please refer to the Nexus user and technical guide for a full detailed description of all possible

LED states and their meanings.

10. Check operation of the unit to ensure that the installation was successful. When powered up, allow a few minutes

to give the battery a small charge, then press the manual test button located at the top right hand side edge of the

unit. Hold the test button in for a few seconds and observe the operation of the lamp switching from mains to the

emergency mode. If the lamp on emergency mode works momentarily, that’s okay. Try again in a few more minutes

because if the battery was completely discharged, it may take a little time to charge up enough to operate even

momentarily. After this time, press the test button again and if the lamp does not work at all, check the supply, the

connections and the trouble shooting guide at the end of this document.

11. If the function test is successful, insert the side diffusers and tighten the thumbscrews by hand (clear polycarbonate

panel must be facing outside). Check and adjust the gasket on the end cover, make sure it is sitting flush on the edge.

Fit the end cover to the enclosure and secure it in place by six M6 torx screws. For wall mount version you may not

need screws on the that side.

Removal instructions

See steps 3 and 4 in the installation instruction.

Testing precautions

Once the fitting is permanently connected to the mains supply, a commissioning discharge test as required in

AS/NZS2293.2 must be carried out. You will need to allow 24 hours for the battery to fully charge prior to conducting

this test, presently (at the time of writing), the standard requires that fittings operate in emergency mode for a period not

less than 2 hours for their commissioning test and for not less than 90 minutes thereafter (it is required that 6 monthly

discharge tests be carried out). You will need to keep the records for the commissioning test and enter them into the

building emergency services logbook or via other recording methods as allowed by AS/NZ2293.2.

Construction sites

Continuously switching of the mains power supply that is connected to emergency light fittings during the construction

phase of an installation will cause these fittings to discharge and charge their batteries many times over a short period;

this can shorten the life of the battery and will also result in shortened emergency lamp life. ABB does not recommend

such practices and may not honour the warranty on batteries when they are subjected to such harsh operating

conditions. Emergency light fittings are designed to be discharge tested once every 6 months as per AS/NZS2293.2,

subjecting the product to repeated discharge or charge cycles is regarded as an abuse of the fittings.

Insert here

to remove

Cable Entry

Holes

Terminal

Block

A

100

500

Figure 1: Ceiling mount Figure 2: Wall mount

Side

407

500

Top

Figure 3: Mains connection and how to get acess to main frame

Active Neutral Earth

Figure 4: Frame insertion diagram