ABB SM3000 User manual

Other ABB Measuring Instrument manuals

ABB

ABB ProcessMaster FEP630 series User manual

ABB

ABB SM1000 User manual

ABB

ABB K-TEK AccuTrak AT500 User manual

ABB

ABB CoriolisMaster FCB400 User manual

ABB

ABB ScreenMaster RVG200 User manual

ABB

ABB Relion 670 series Quick start guide

ABB

ABB DATUM L150 User manual

ABB

ABB Comem eOLI22 User manual

ABB

ABB 8002 User manual

ABB

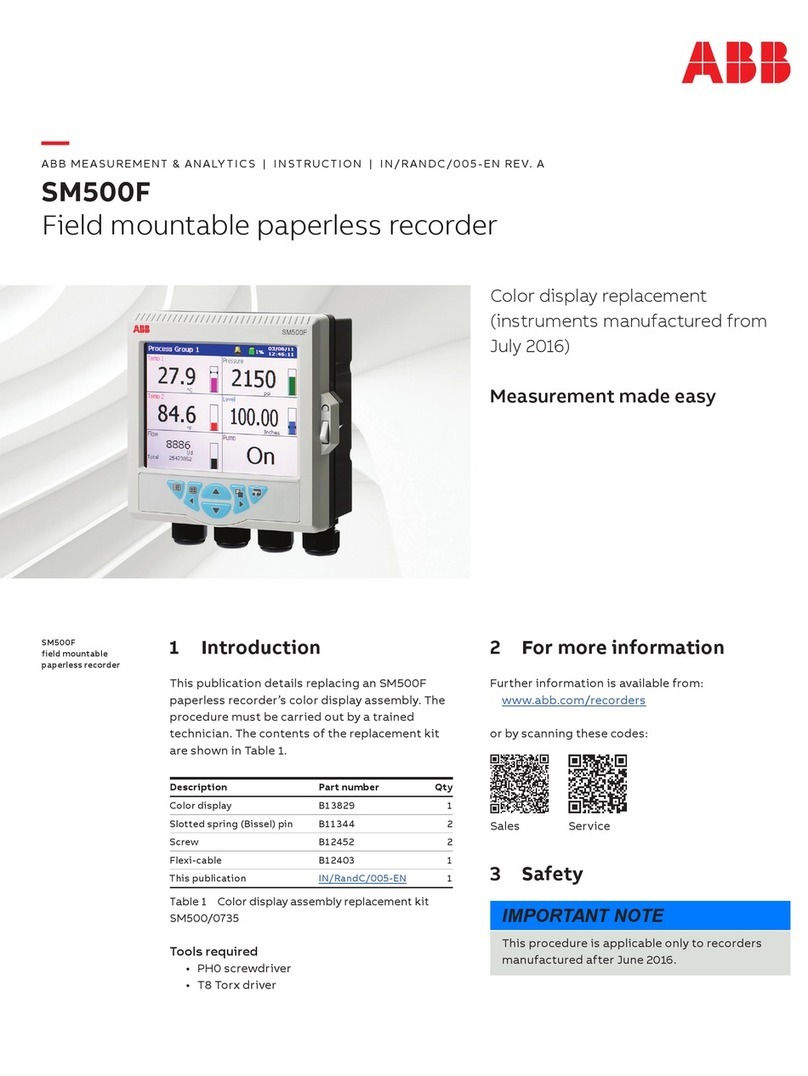

ABB SM500F User manual

ABB

ABB Navigator 600 Silica User manual

ABB

ABB GLA232 Series User manual

ABB

ABB ProcessMaster FEM630 User manual

ABB

ABB EasyLine EL3000 User manual

ABB

ABB CoriolisMaster FCM2000 User manual

ABB

ABB CoriolisMaster FCM2000 Training manual

ABB

ABB EV1 User manual

ABB

ABB XFC6200EX User guide

ABB

ABB LS4000 User manual

ABB

ABB C1900 Series User manual