USING THE PANEL

- Turning the panel on

Each time the power is turned on, it will start beeping for 30 seconds. This function is used to stabilise the operating conditions of the

handset line and to restore the default codes and panel settings. It can always be cancelled using lower call button or the "#" button.

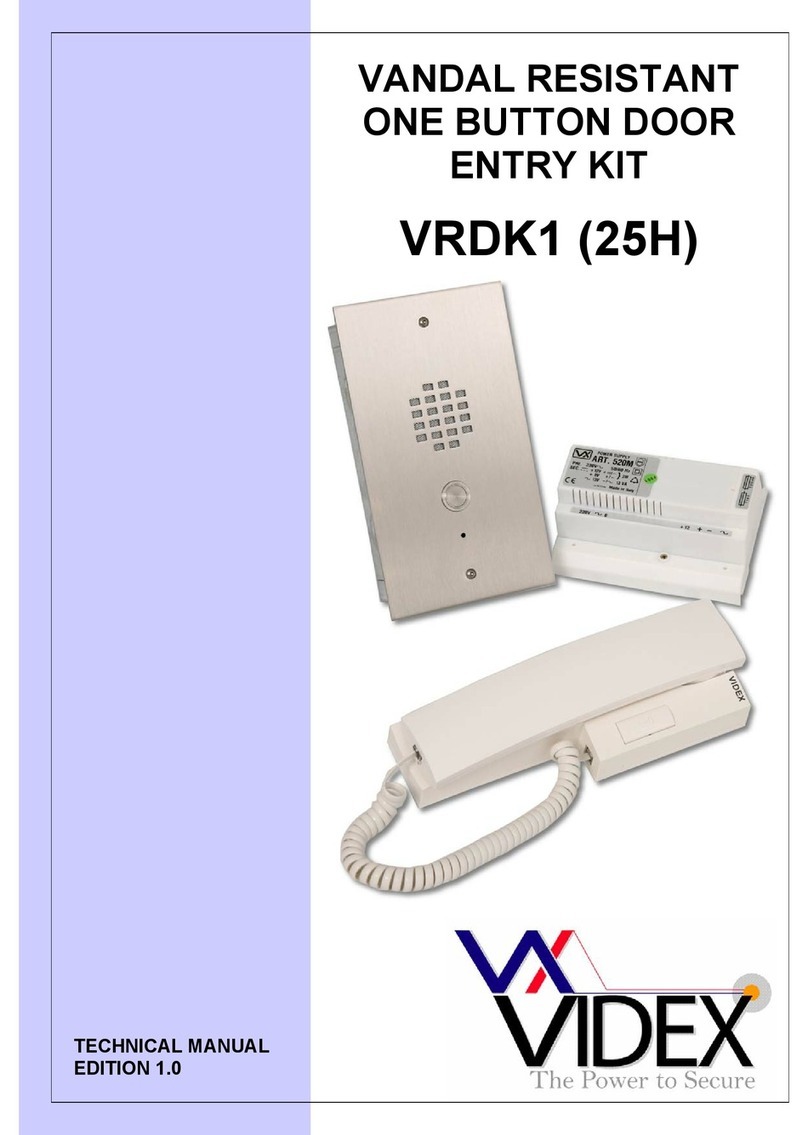

- Calling:

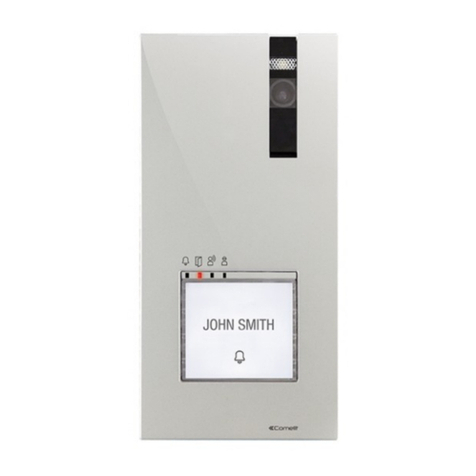

Panels with direct call buttons: To call the subscriber press the appropriate ringer button - the handset in the apartment being

called will start ringing.

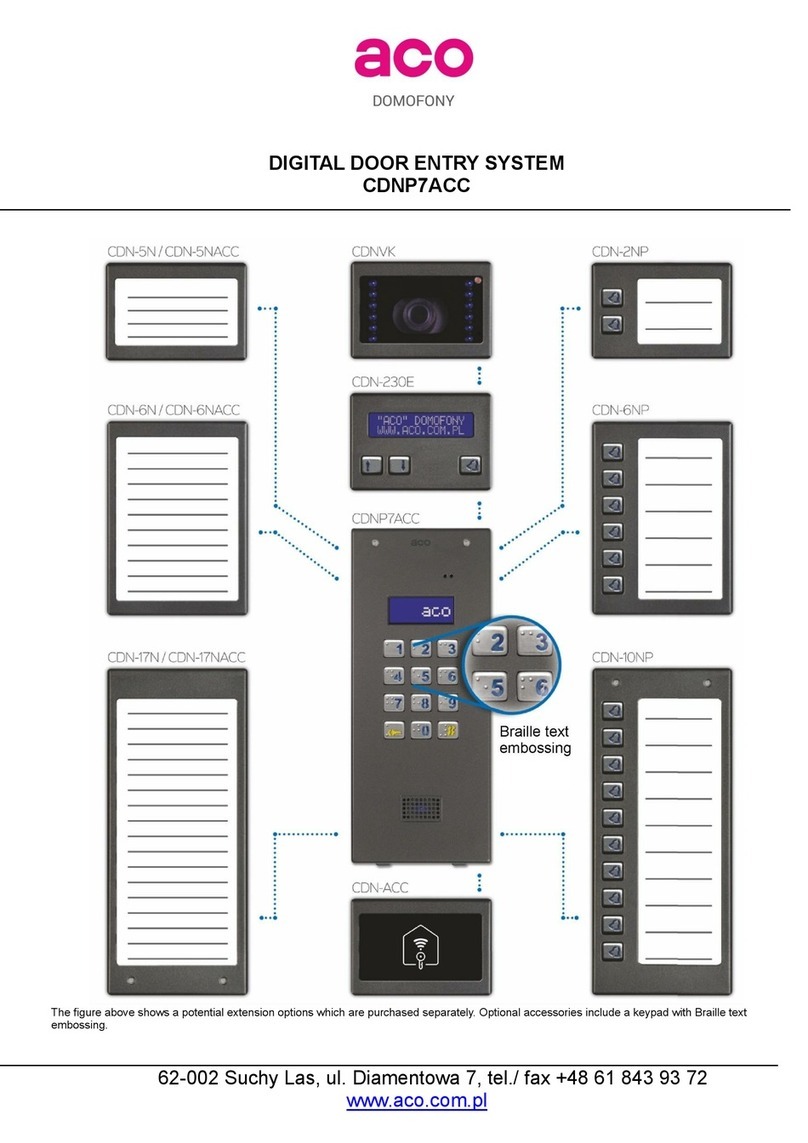

Panels with only the numeric keypad: To call the subscriber, select the number of the apartment using the keys on the keypad

(pre-set from 1 to 10). Within 3 seconds the indoor unit in the apartment will start ringing.

The panel sends two ringing tones and sets itself to stand by waiting for the handset to be picked up. If the call is not answered within

20s, another single signal is sent. If the monitor handset is not picked up within approximately 40s, the panel will automatically switch

from calling to standby mode. Calling can be cancelled at any time by pressing the "#" button. If the call is answered, the connection

to the panel is established. Now conversation is possible and the door can be opened. The connection can last up to 2 minutes.

- Using a code or proximity key fob (ACC) :

To open the door (to the E-lock), use the code by entering it on the numeric keypad or, in panel standby mode, by placing a key

fob to the lowest description window. For panels with a numeric keypad and direct dial buttons, the pre-set codes are 1111 (for the

lower button), 2222 (for the upper button). For panels with only a numeric keypad itself, use the resident code from the pre-

programmed code table (code table attached to the panel). To do this, select the number of the apartment, press the "key" button

and then select the relevant code (assigned to the apartment as per the code table).

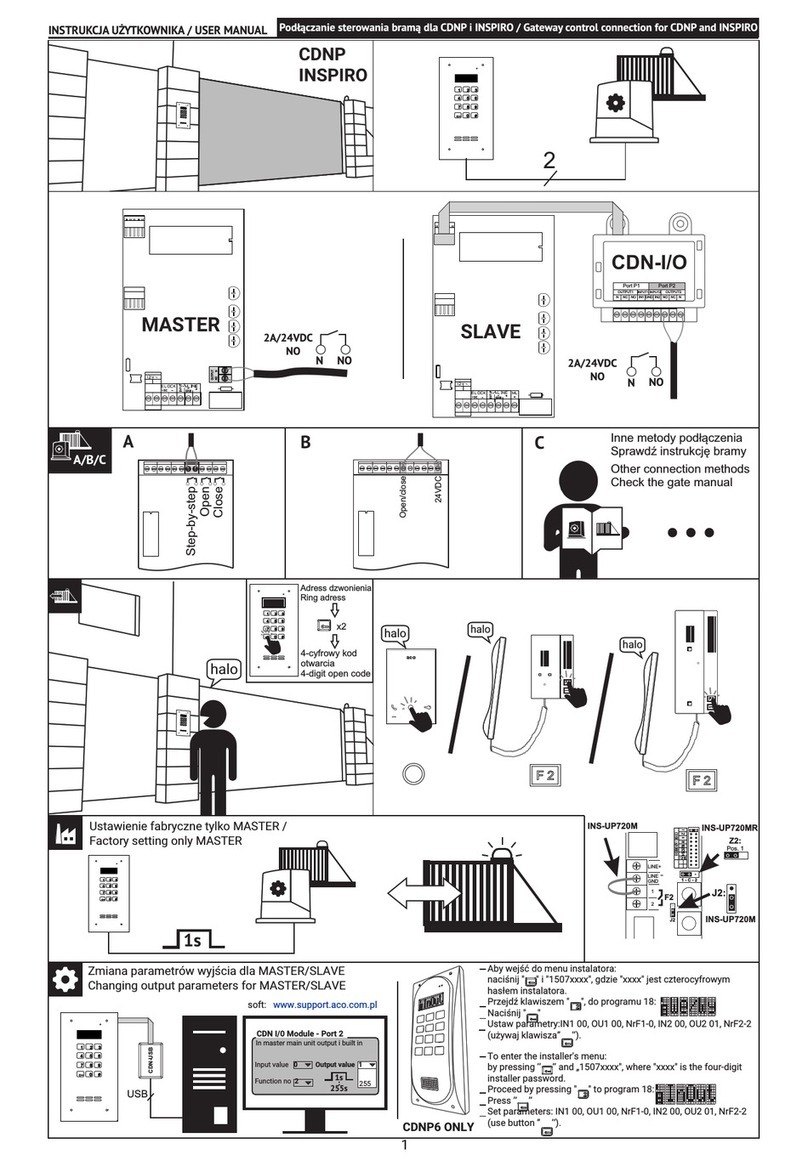

If the code (or the proximity card) is preceded by pressing the key twice, it will activate an additional device, such as a gateway

(this requires an optional I/O module connected to the panel).

The panel has a function to notify residents when the code or proximity card or key fob is used - by a short triple beep emitted

by the handset to which the code or key fob is assigned.

Note! It is recommended to change the codes upon installation of the panel is complete. Code change by the user in panels with

direct call buttons: Enter the current code, then within 1.5 second press and hold the "key" button (for approximately 4s), until the

panel emits the sound of accessing the code change procedure. Then enter a new four-digit code. For panels with only the numeric

keypad, the code can be changed from the installer’s menu (refer to extended user instruction).

To add and remove proximity key fobs, use the ACC computer program, version v3.5 or later, available at www.aco.com.pl. and

connect the panel to the computer using the optional CDN-USB cable (to be purchased separately).

- Restoring codes and panel settings to factory default settings and deleting all key fobs:

Turn the panel power supply off, wait 5 seconds, turn the power on again. The panel will beep for 30 seconds. Press the "#"

button during this time and press at the same time (immediately) press:

- keys 1 and 7 to restore the lower key code to 1111 (for panels with direct dial buttons)

- keys 2 and 7 to restore the top button code to 2222 (for panels with direct dial buttons)

- keys 2, 5, 8 to restore all factory settings, including both codes (in models without a numeric keypad, press the lower calling key

after the first beep that can be heard after power is turned on and hold it until the factory settings reset procedure is started).

- Restoring codes and panel settings to factory default settings and deleting all key fobs:

Turn the panel power supply off, wait 5 seconds, turn the power on again. The panel will beep for 30 seconds. Press the "#"

button during this time and press at the same time (immediately) press:

- keys 1 and 7 to restore the lower key code to 1111 (for panels with direct dial buttons)

- keys 2 and 7 to restore the top button code to 2222 (for panels with direct dial buttons)

- keys 2, 5, 8 to restore all factory settings, including both codes (in models without a numeric keypad, press the lower calling key

after the first beep that can be heard after power is turned on and hold it until the factory settings reset procedure is started).

- Handset line failure: The panel detects failures (short circuit) of the handset line - indicated by blinking of keypad backlight. During

this time, E-lock can be activated by pressing any button and building can be entered. When the correct state of the line is detected

(when short circuit ceases), the panel is automatically restored to normal operation.

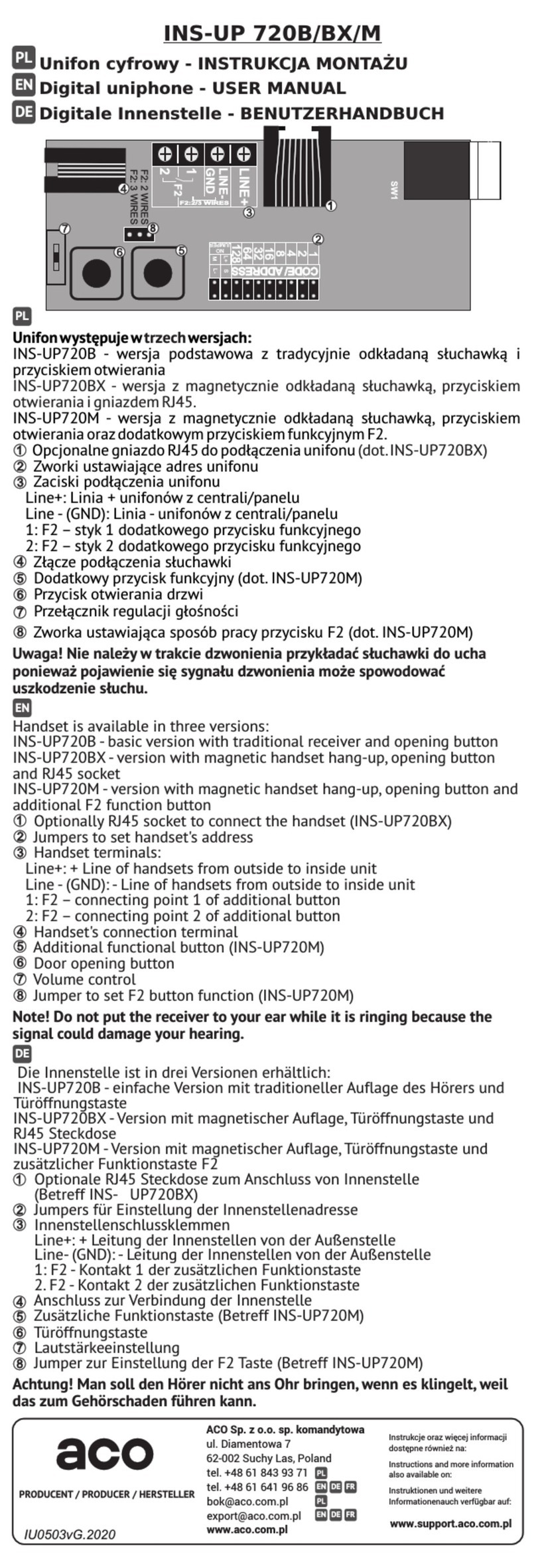

USING THE OPERATION

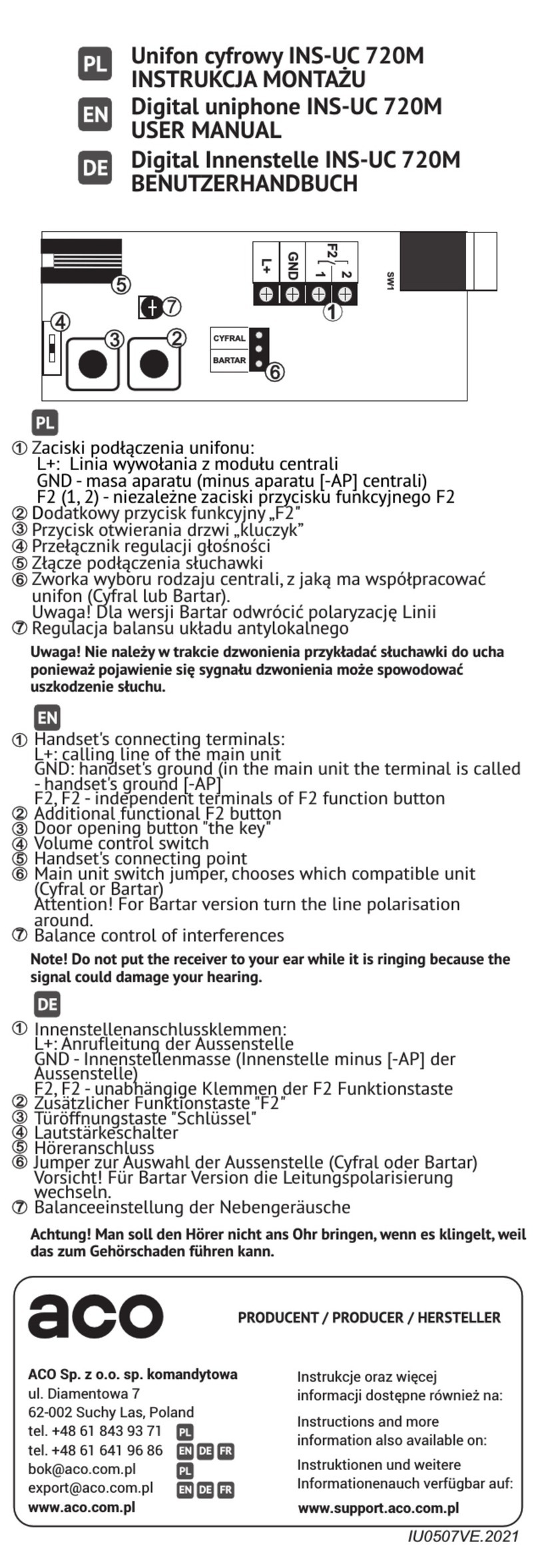

To answer the call while it is ringing, simply pick up the handset of the monitor. During the connection, it is possible to open the

door using the “key” button. Additional devices, such as a gateway, can be activated using the "F2" function key (only with optional

I/O module connected to the panel).

The call ends automatically when the handset is hung up.

The ringing volume of the monitor can be adjusted in stand-by mode (using the switch at the bottom of the unit). Door

can be opened in standby mode by pressing the “key” button.

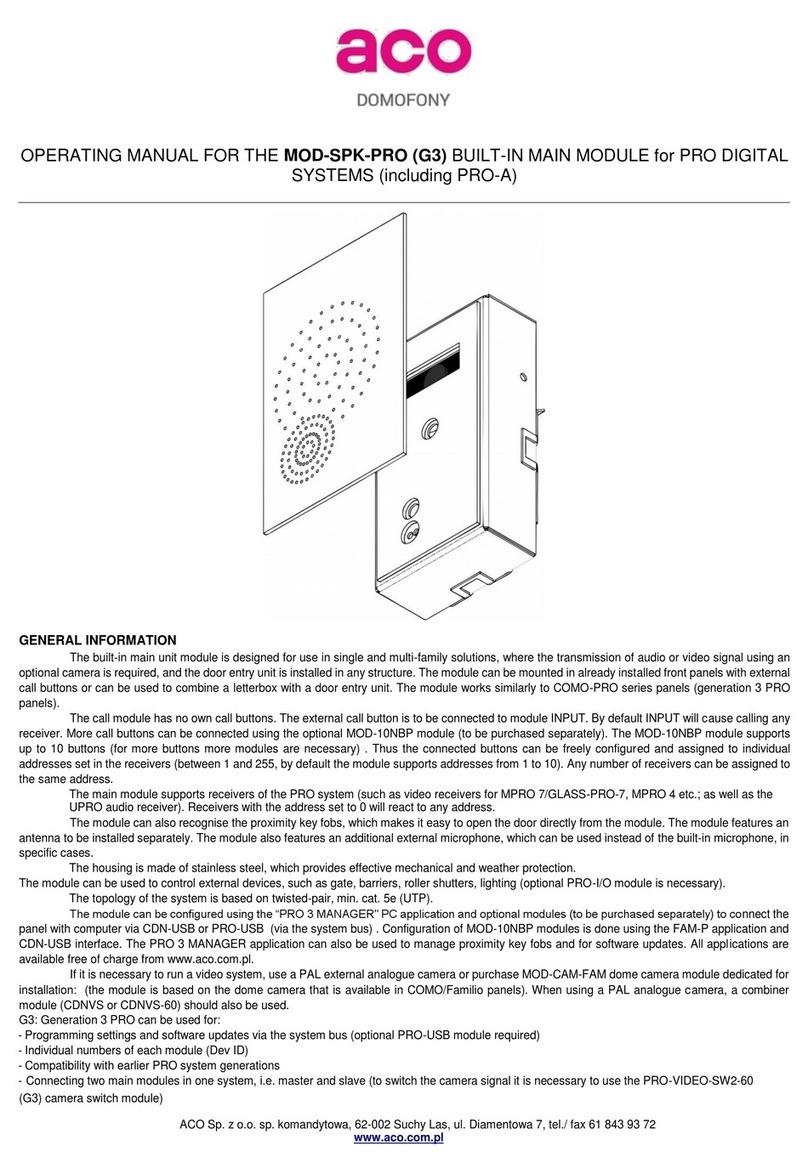

Refer to the extended user manual of FAM-PV series panels available at www.aco.com.pl to find out more features of the FAM-PV

series panels (programming advanced functions, systems with greater number of panels, interconnection with other ACO systems:

CDNP, Inspiro, and basic troubleshooting). All settings may also be changed using the FAM_P computer software.

Software can be downloaded from www.aco.com.pl. (Connect the panel to the computer using the optional CDN-USB

cable.)

RULES FOR STORING WASTE ELECTRICAL EQUIPMENT

Waste electrical equipment must not be disposed of with other waste. It should be stored in places designated for this purpose. For

this purpose, please contact the responsible institutions or companies involved in waste recycling.

- Directive 2002/96/EC of 27.01.2003

IU0204enVG.1950