1 Automatic-L-230411-Rev002-UM-en

CONTENTS

1. FOREWORD......................................................................................................................... 2

2. INTENDED USE.................................................................................................................... 2

3. ILLUSTRATIONS.................................................................................................................. 3

4. START-UP AND SAFETY PRECAUTIONS.......................................................................... 4

4.1 Opening the packaging.......................................................................................................... 4

4.2 Installation............................................................................................................................. 4

4.3 Wiring.................................................................................................................................... 4

4.4 Mechanical safety devices..................................................................................................... 5

4.5 Acceptance testing ................................................................................................................ 5

5. OPERATING THE SLICER ................................................................................................... 6

5.1 Manual operation................................................................................................................... 6

5.2 Automatic operation............................................................................................................... 7

5.3 Switching off.......................................................................................................................... 7

5.4 Using the machine................................................................................................................. 7

6. CLEANING AND CARE........................................................................................................ 8

6.1 Cleaning................................................................................................................................ 8

6.2 Lubricating............................................................................................................................. 9

7. SHARPENING THE BLADE ............................................................................................... 10

8. TRAINING........................................................................................................................... 12

9. STORAGE AND TRANSPORTATION CONDITIONS......................................................... 12

10. DISPOSAL.......................................................................................................................... 12

11. WARRANTY........................................................................................................................ 12

12. TECHNICAL DATA............................................................................................................. 12

13. DIAGRAMS......................................................................................................................... 13

14. DECLARATION OF CONFORMITY.................................................................................... 14

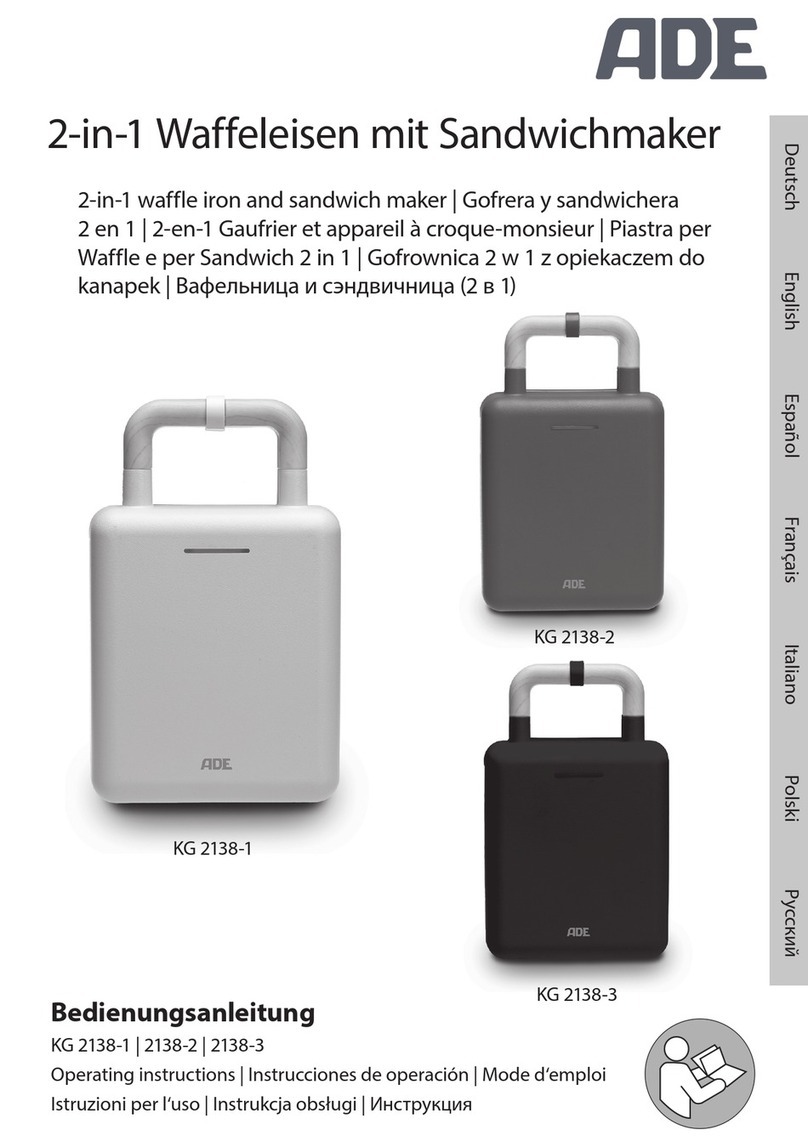

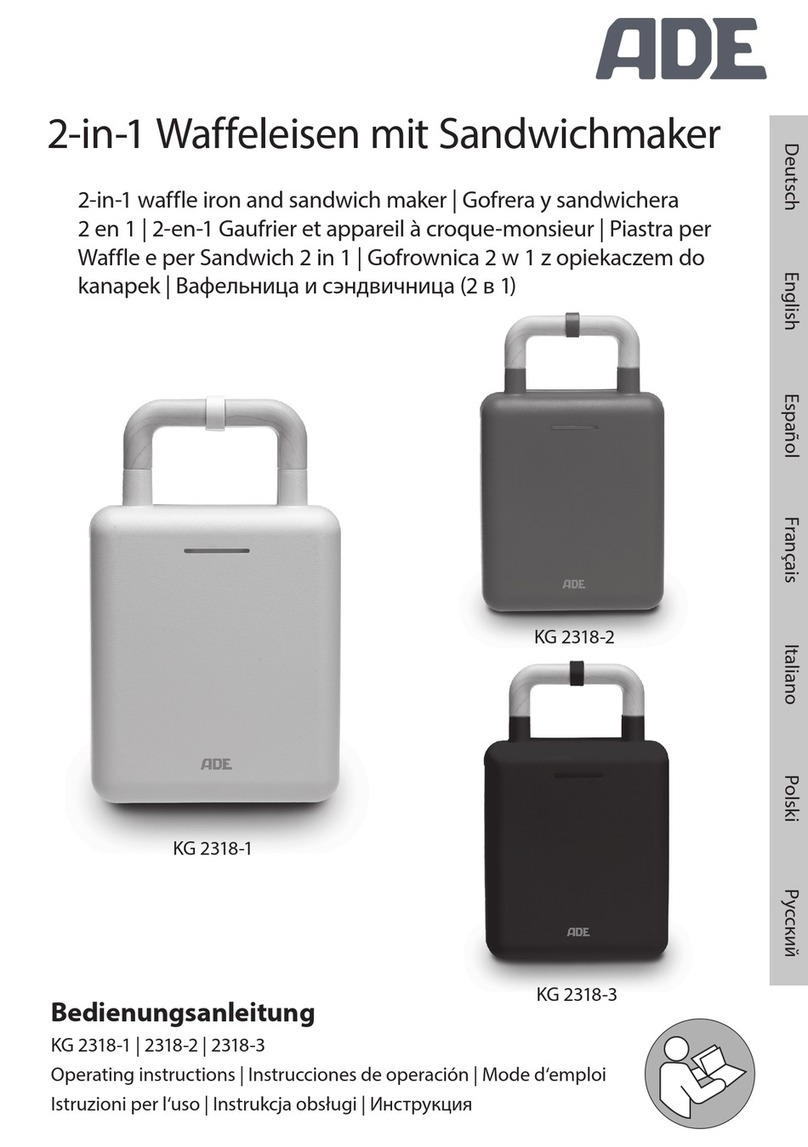

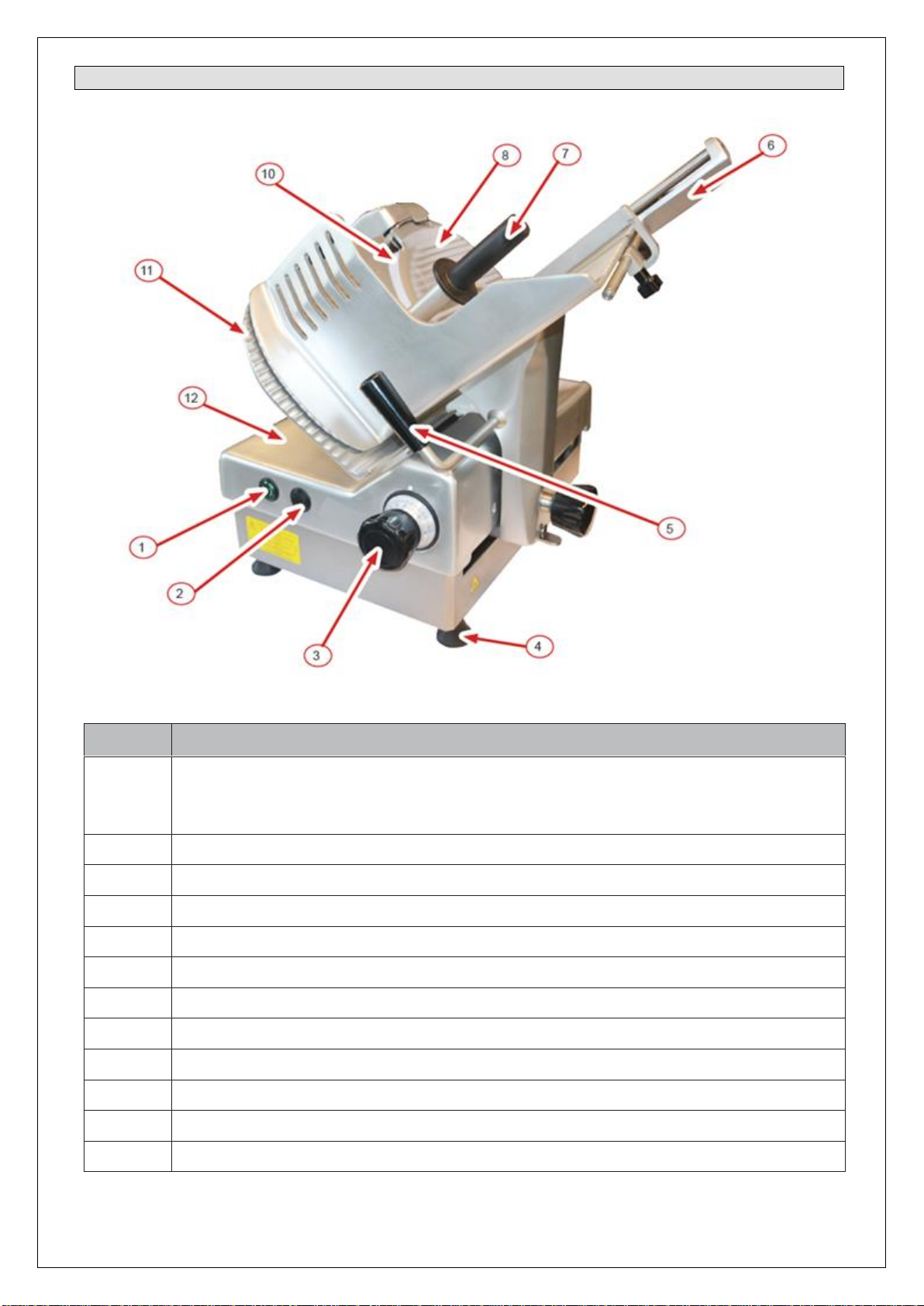

* The illustration shows a machine with accessories not included. An integrated blade sharpener is

not part of the machine.