5. SERVICING AND MAINTENANCE OF THE MEAT SLICING MACHINE

For hygienic reasons meat slicing machines must be kept clean at all times. They must be disassembled and

cleaned both at the end of each working day and each time the type of product being cut is changed (e.g.

from fresh to cooked meat).

5.1 Cleaning

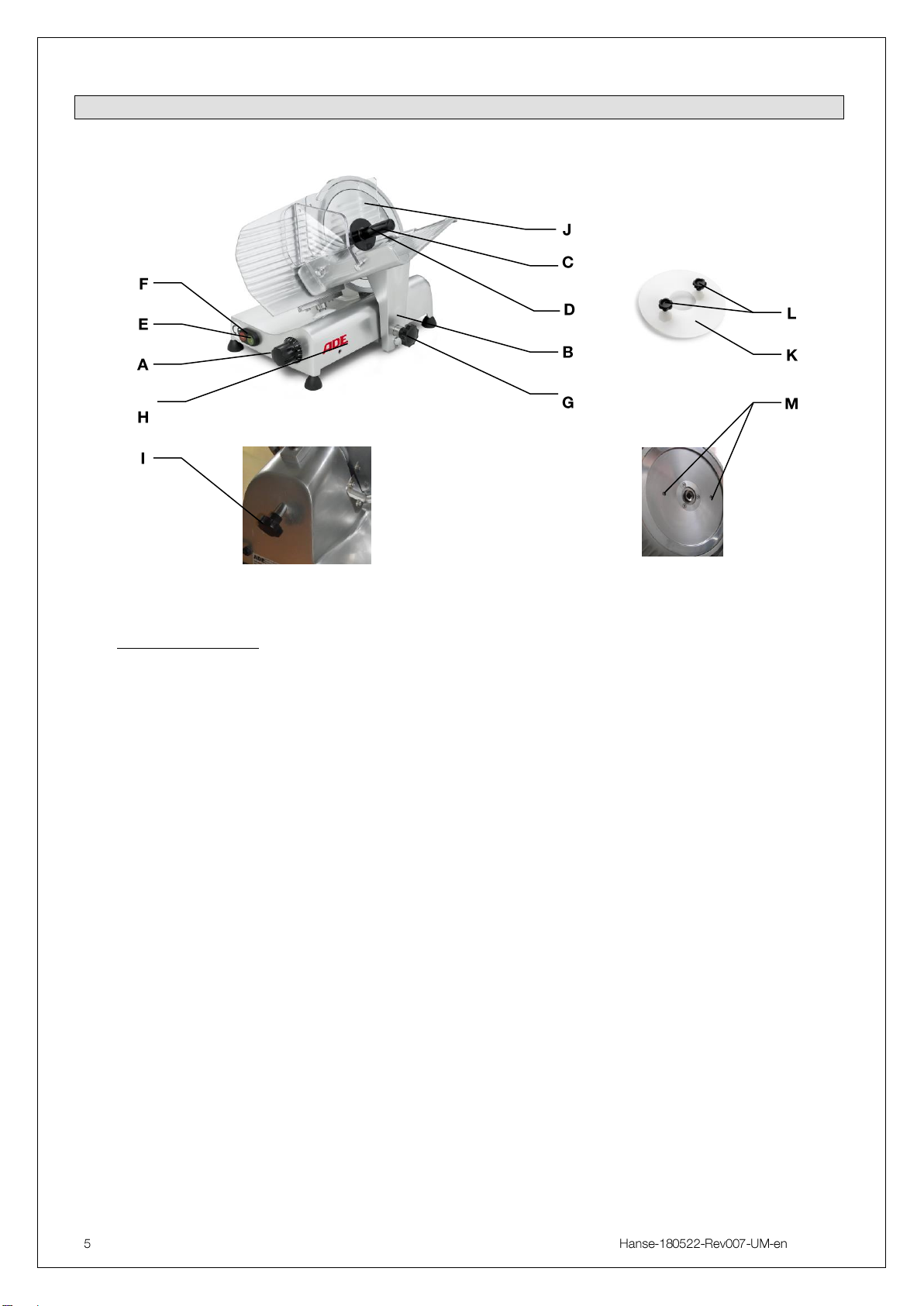

1) Remove the plug from the socket in order to disconnect the machine from the electrical supply. Note that

pressing the red stop button on the machine "F" can in no way be considered adequate disconnection of

the machine.

2) Set the thickness setting knob "A" to "0" (null) or its end position before removing the carriage.

3) Completely unscrew the handwheel "G", regardless of its position.

4) Use light pressure to pull the holding carriage back to its end stop "H", releasing the blocking unit lock.

The holding carriage can now be lifted vertically upwards from its guides, with the cut adjustment knob

remaining locked at position "0".

Like all other removable parts of the machine, the carriage may not be cleaned in a dishwasher!

5) Completely unscrew the hand screw "I" and remove the blade protecting plate "J" using suitable protec-

tive clothing, such as, for example chain mail gloves.

6) If the optional blade removal tool has been purchased:

Position the blade removal tool "K" over the holes "M", provided in the blade and fasten the two together

by screwing the two thumbscrews "L" into the threads.

7) Undo the screws holding the blade using a screwdriver and remove the complete blade using both

thumbscrews.

8) Once dismounted, wash the cutting blade with warm water and a liquid cleaner, rinse with clean water,

allow to dry and then disinfect using, for example, alcohol. The machine base and the other components

must always be cleaned with warm water and liquid cleaner and a non-scratching cloth. These parts

should also be rinsed with clean water, allowed to dry and then be disinfected, for example, using alco-

hol. Under no circumstances should abrasive cleaners or bleaches (i.e. cleaners based on sodium hypo-

chlorite) be used as these would permanently damage the machine surface.

9) Assembly of the machine is to be carried out in the reverse order to that described above.

Ensure that when cleaning the blade water does not enter the blade hub as this can lead to damage

to the bearings, motor and other components in the machine. In addition, note that water can cause

rusting when not allowed to dry off properly.

Under no circumstances may either the machine or its components be cleaned using a water jet or

high pressure cleaner.

Neither the carriage. the blade cover plate nor other removable parts may be cleaned in a dish-

washer!

The cutting blade guard is a particularly important protective device and may only be removed when

the blade is secured in its normal position with screws.

5.2 Lubrication

The slicing machine holding carriage and holder guides must be regularly lubricated in order to ensure that

they always slide freely. Only high quality acid and resin-free vaseline oil (e.g. ESSO MARCOL 82 or

BERGOIL WHITE OIL 105) should be used; this type of lubrication should be carried out regularly using small

quantities of lubricant.