1 FL-200128-Rev007-UM-en

Inhaltsverzeichnis

Inhaltsverzeichnis ........................................................................................................................... 1

Safety information........................................................................................................................... 2

General safety instructions.......................................................................................................... 2

Personal safety ........................................................................................................................... 2

Safety of the device .................................................................................................................... 3

Work area safety......................................................................................................................... 3

Safety in maintenance ................................................................................................................ 4

Residual risks ............................................................................................................................. 4

Intended use................................................................................................................................... 4

Exclusion of use:......................................................................................................................... 4

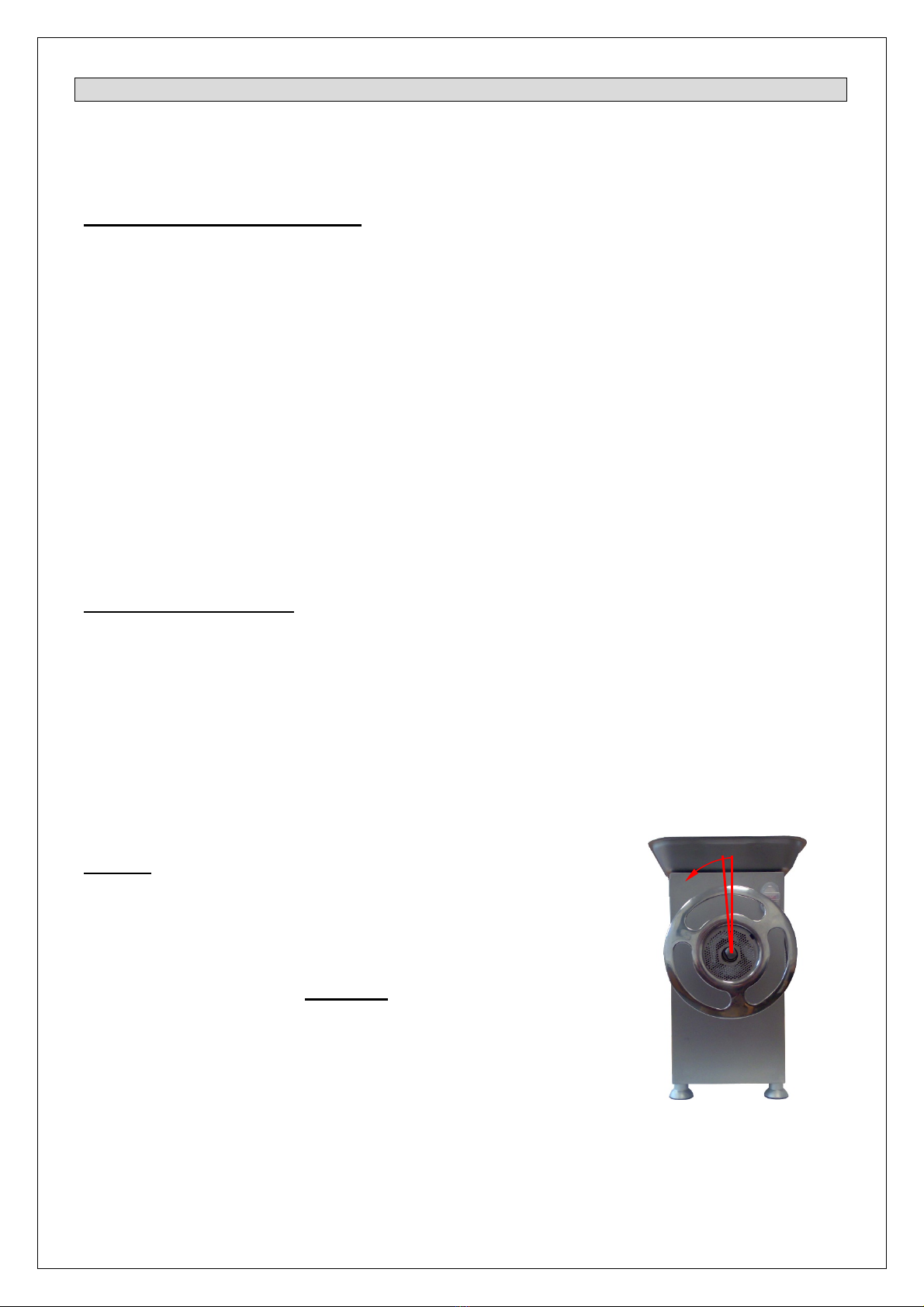

Installing and setting up the meat mincer........................................................................................ 5

Inspecting the contents of the box............................................................................................... 5

Installing the meat mincer ........................................................................................................... 5

Start-Up ...................................................................................................................................... 5

Operating the meat mincer ............................................................................................................. 6

Power On and Off ....................................................................................................................... 6

Operating the meat mincer.......................................................................................................... 6

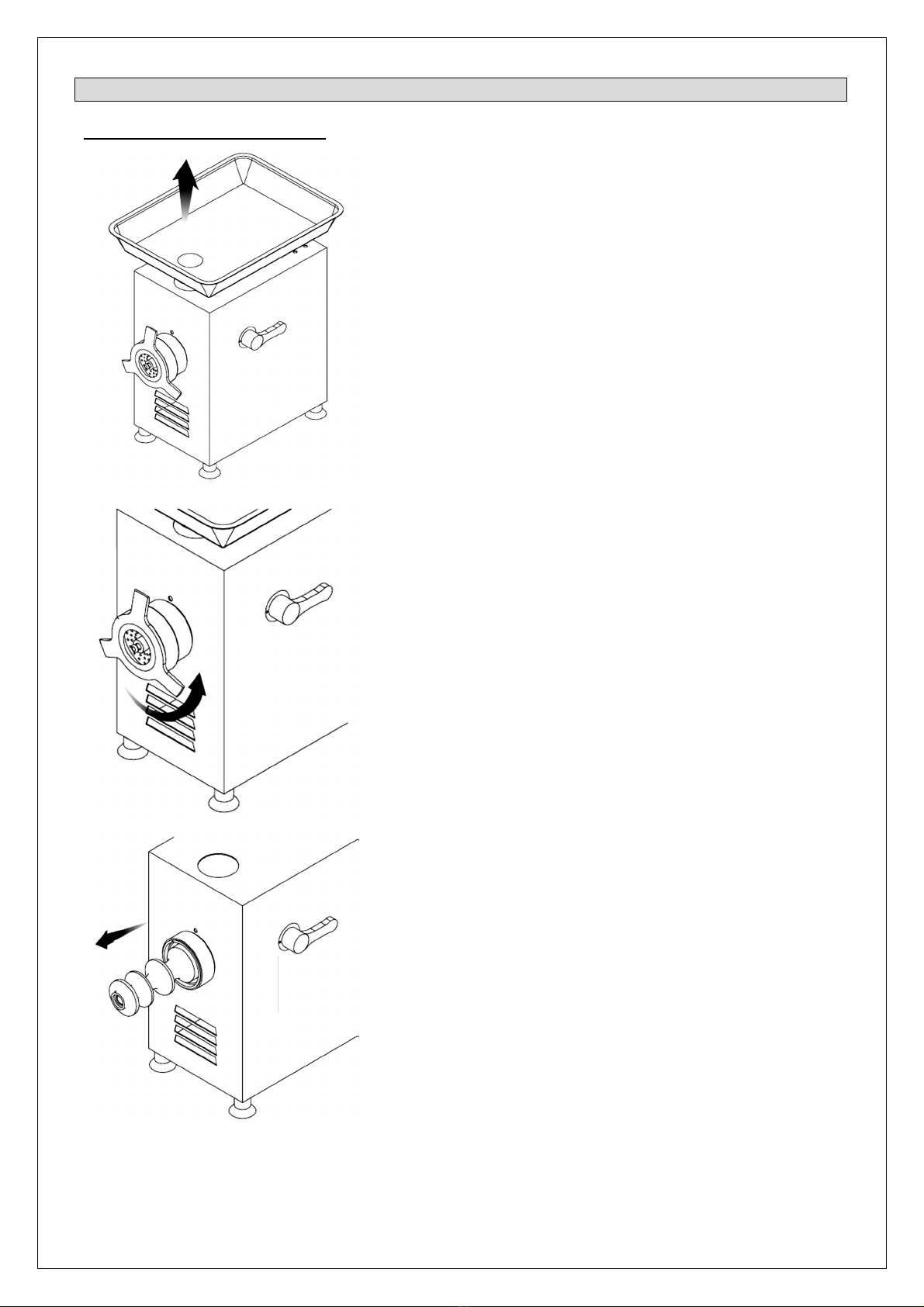

Dis- and Reassembling the cutting set............................................................................................ 7

Disassembling the cutting set ..................................................................................................... 7

Reassembling the cutting set ...................................................................................................... 8

Changing the cutting set ............................................................................................................. 9

Cleaning, maintenance and servicing, disposal............................................................................... 9

Disassembling the meat mincer for cleaning............................................................................... 9

Cleaning ..................................................................................................................................... 9

Troubleshooting ........................................................................................................................ 10

Storage and Transport Conditions ............................................................................................ 10

Warranty ................................................................................................................................... 10

Disposal.................................................................................................................................... 10

CE marking and declaration of conformity..................................................................................... 11

Technical Data.............................................................................................................................. 12

Exploded view .............................................................................................................................. 13

Spare parts list.............................................................................................................................. 15

Block diagram............................................................................................................................... 16