1 Juwel-200624-Rev010-UM-en

CONTENT

0.

FIGURES ...................................................................................................................................................2

1.

FOREWORD..............................................................................................................................................4

2.

INTENDED USE ........................................................................................................................................4

3.

PREPARATION AND OPERATION ..........................................................................................................4

3.1

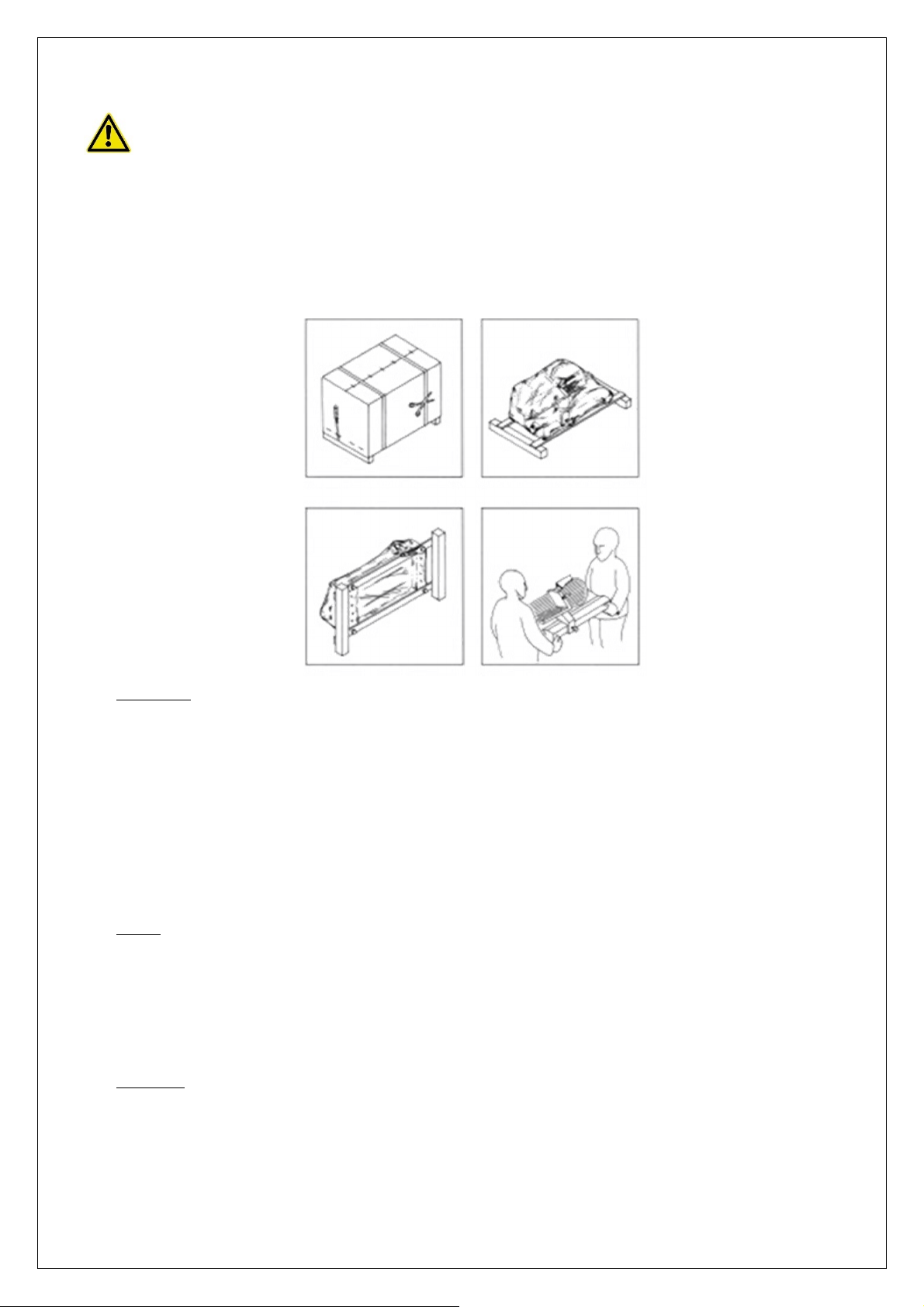

Opening the packaging ..............................................................................................................................4

3.2

Installation ..................................................................................................................................................5

3.3

Wiring .........................................................................................................................................................5

3.4

Operation ...................................................................................................................................................5

4.

CONTROLS AND SAFETY DEVICES ......................................................................................................6

4.1

Controls......................................................................................................................................................6

4.2

Mechanical safety devices .........................................................................................................................6

4.3

Testing .......................................................................................................................................................6

5.

USING THE SLICER .................................................................................................................................7

5.1

Operating procedure ..................................................................................................................................7

6.

MAINTENANCE AND CARE OF THE SLICER.........................................................................................7

6.1

Cleaning .....................................................................................................................................................7

6.2

Lubricating..................................................................................................................................................8

7.

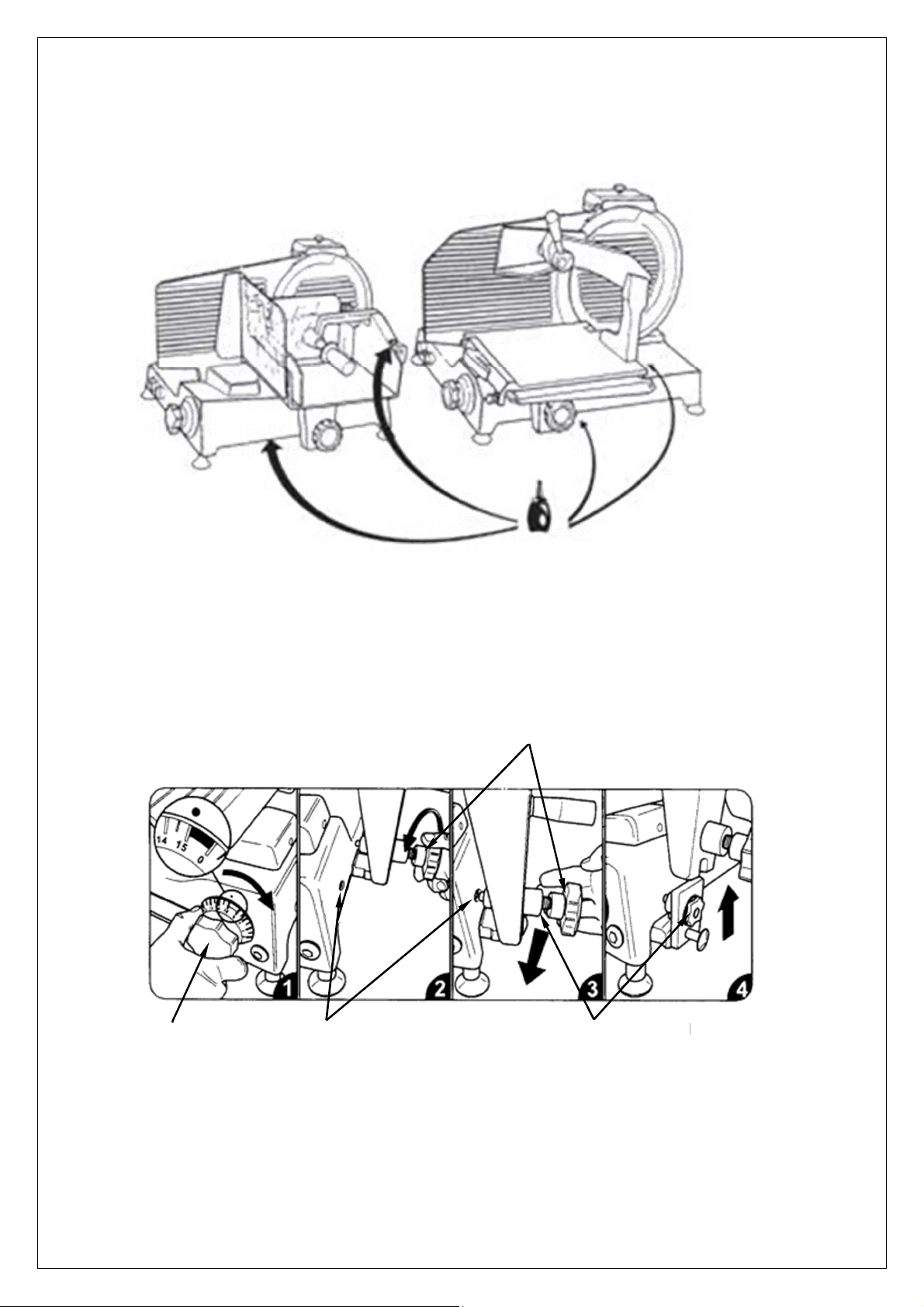

SHARPENING OPERATIONS...................................................................................................................8

7.1

Sharpening blade.......................................................................................................................................8

8.

CLEANING AND MAINTENANCE.............................................................................................................9

9.

TRAINING ................................................................................................................................................10

10.

WARRANTY.............................................................................................................................................10

11.

TECHNICAL FEATURES ........................................................................................................................11

12.

CE – Declartion of conformity ..................................................................................................................11

13.

WIRING DIAGRAMS ...............................................................................................................................12

14.

EXPLODED VIEWS.................................................................................................................................13

15.

SPARE PARTS SERIES JUWEL ............................................................................................................19